Bendable single substrate lithium-air battery series connection structure

An air battery, series structure technology, applied in the direction of structural parts, battery pack parts, circuits, etc., can solve the problems of metal lithium anode sensitivity, limiting energy density and safety performance, which cannot solve the requirements of internal air electrode diffusion, and achieves Achieve bendability and pressure resistance, increase energy density, and achieve flexible tandem structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

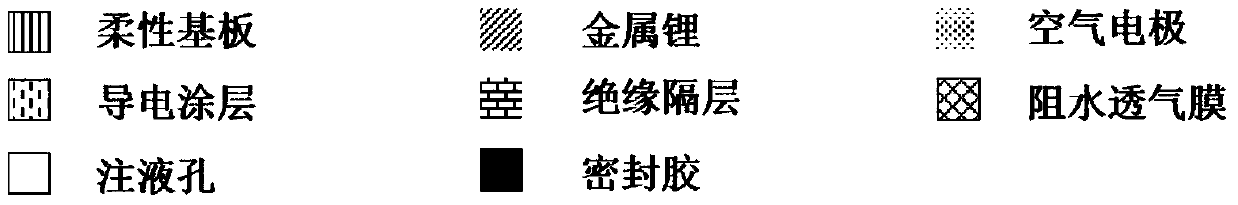

[0029] Such as figure 1 As shown, the flexible substrate is a polyethylene naphthalate film with a thickness of 200 microns, the conductive coating is a fluorine-doped tin oxide film with a thickness of 50 nanometers prepared by magnetron sputtering, and the surface is patterned by laser etching, and the metal lithium It is a common lithium strip for lithium batteries that is laminated on the surface of fluorine-doped tin oxide through a laminator. The insulating interlayer is a 2-5 micron zirconia porous film with a thickness of 2-5 microns prepared by the mask plate magnetron sputtering method. The air electrode is a commercial The carbonized carbon material KB600 and polytetrafluoroethylene are used as the active material and the binder of the air electrode prepared by rolling method, respectively, and the water-blocking and breathable membrane is made of 10-micron polyethylene terephthalate bonded to fluorine-doped tin oxide by hot-pressing sarin resin. Ethylene glycol for...

Embodiment 2

[0031] Such as figure 1 As shown, the flexible substrate is a metal-polymer composite film with a thickness of 500 microns polyethylene terephthalate-aluminized / polyethylene / reinforcing layer / polyethylene, and the conductive coating is prepared by vacuum thermal deposition combined with a mask plate The aluminum metal film with a thickness of 20 nanometers, the metal lithium is a lithium strip commonly used in lithium batteries that is laminated on the surface of metal aluminum by a laminator, and the insulating interlayer is silicon oxide with a thickness of 2-5 microns prepared by combining a mask plate magnetron sputtering method Porous film, the air electrode is cobaltous oxide nanowire and polyvinylidene fluoride prepared by hydrothermal synthesis method respectively as the active material and the air electrode prepared by the binder rolling method, and the water-blocking and breathable film is cured by ultraviolet light. 10 micron polyethylene naphthalate film bonded to ...

Embodiment 3

[0033] Such as figure 1 As shown, the flexible substrate is a metal titanium plate whose surface is oxidized to form a titanium oxide passivation layer, and the conductive coating is formed by vacuum thermal deposition of metal aluminum on the surface oxidation treatment titanium plate of the photoresist mask and then etching the photoresist A patterned aluminum metal film with a thickness of 20 nanometers. The metal lithium is a lithium strip commonly used in lithium batteries that is laminated on the surface of metal aluminum by a laminator. The insulating interlayer is a polypropylene film vacuum-evaporated with a mask plate. The air electrode is the surface Graphene and polytetrafluoroethylene loaded with cobaltous oxide particles in situ were used as the active material and the air electrode prepared by the binder rolling method, respectively, and the water-blocking and gas-permeable membrane was a thermally poured polydimethylsiloxane film. After the battery is packaged,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com