Chromium ore composite pellet used for reduction in argon-oxygen refining furnace, production method and application thereof

A technology of argon-oxygen refining furnace and composite pellets, which is applied in the field of chromium ore composite pellets for argon-oxygen refining furnace reduction, can solve the problems of winding scale defects, large amount of electric furnace slag, and high content of iron oxide in the final slag, and achieve improvement The effect of desulfurization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

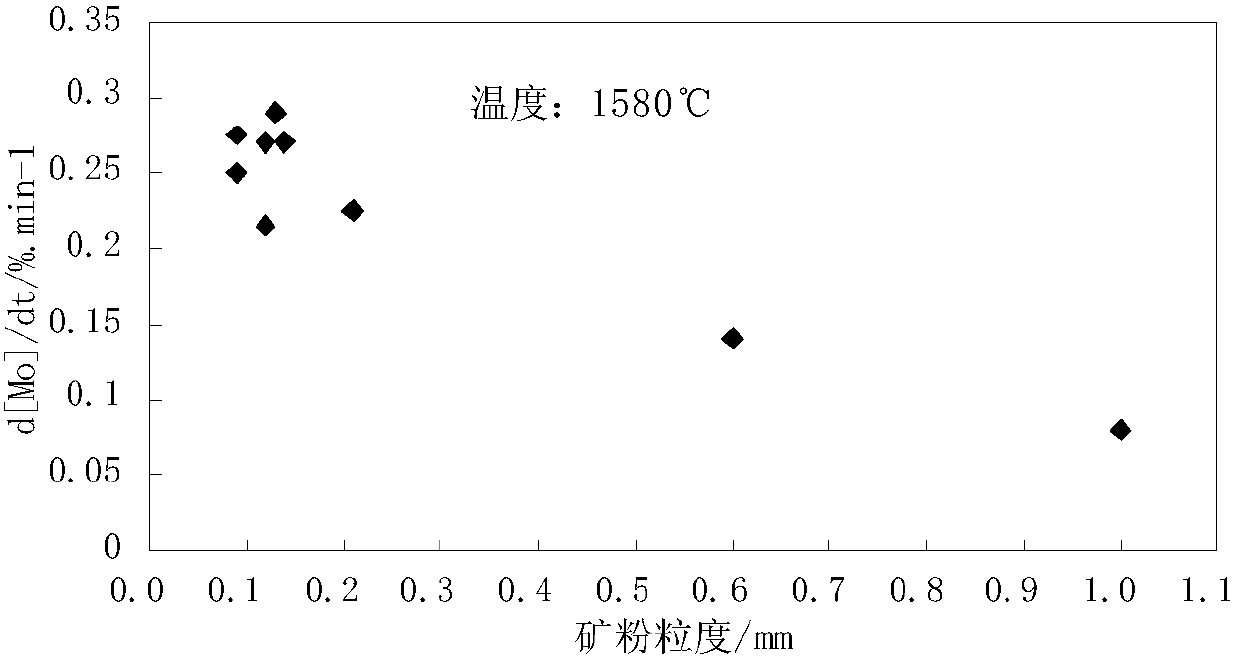

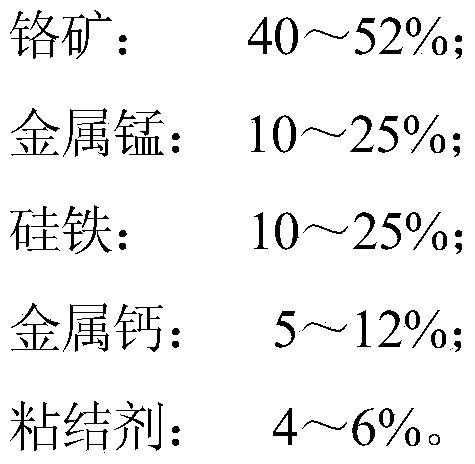

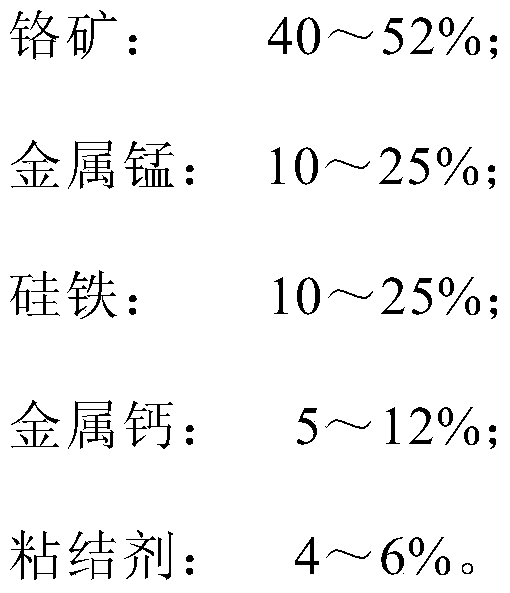

[0034] A kind of chromium ore composite pellet for argon oxygen refining furnace furnace, its component weight percent is:

[0035]

[0036] Various materials further described are:

[0037] The chrome ore is: preferably, Cr in the chrome ore 2 o 3 The mass percentage content is 40.0~50.0%;

[0038] Metal manganese is: preferably, the mass percentage of manganese is ≥97.0%;

[0039] Ferrosilicon is an iron-silicon alloy made of coke, aluminum powder, steel shavings, quartz (or silica) and smelted in an electric furnace. Preferably, the mass percentage of silicon in ferrosilicon is ≥72.0-80.0%, and the mass percentage of carbon is ≤0.50%;

[0040] Calcium metal is obtained by using limestone as raw material, aluminum powder as reducing agent, and processing after cooling by vacuum reduction method. Preferably, the mass percentage of calcium is ≥97.0%;

[0041]The binder is: sodium methyl cellulose, other binders are easy to cause carburization of molten steel.

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com