Silk woven medical suture with color discrimination and anti-bacterial functions and preparing method thereof

A technology for color identification and suture, applied in the field of medical textiles, can solve the problems of high requirements on the type of polymer absorbable materials, complex processing technology, and potential safety hazards, and achieves soft and delicate hand feel, short process flow, and easy soaping. and washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

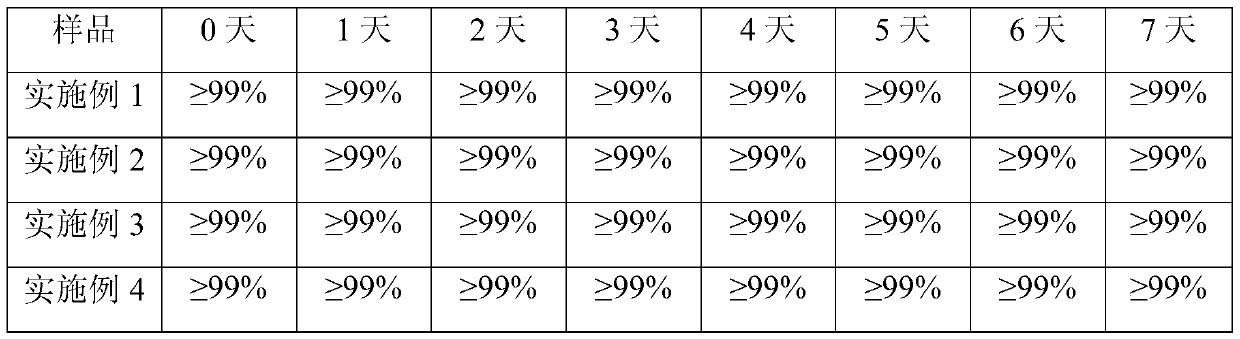

Examples

preparation example Construction

[0025] A method for preparing a silk braided medical suture with both color recognition and antibacterial functions, comprising the following steps:

[0026] a Weigh natural dyes with 5-10% mass of silk threads, add the natural dyes to distilled water 30-50 times the mass of silk threads and dissolve them for 5-10 minutes to obtain a dyeing solution; then soak the silk threads into the prepared dyeing solution , raising the temperature of the dyeing solution to 40-50° C., incubating and dyeing for 10-20 minutes, then raising the temperature of the dyeing solution to 70-80° C., and incubating and dyeing for 70-90 minutes to obtain dyed pretreated silk threads. The natural dye can be gallnut or Keshu or oak leaf, the silk thread is a single thread, and the linear density specification of each thread can be 13 / 15D or 17 / 19D or 20 / 22D or One of 27 / 29D or 30 / 32D or 40 / 44D.

[0027] Existing silk dyeing process is to carry out degumming pretreatment to silk earlier, adopts syntheti...

Embodiment 1

[0039] a Weigh 1 kg of silk thread with a linear density specification of 13 / 15D, then weigh 50 g of Galla gall natural dye, add the weighed natural dye to 30 kg of distilled water and dissolve for 5 minutes to obtain a dyeing solution. Then soak the silk thread in the prepared dyeing solution, raise the temperature of the dyeing solution to 40° C., keep it warm for 20 minutes, then raise the temperature of the dyeing solution to 70° C., keep it warm for 90 minutes, and obtain the dyed pretreated silk thread.

[0040] b prepare 30kg concentration of acetic acid aqueous solution of 0.5g / L, then add 150g FeSO 4 Add to acetic acid aqueous solution and dissolve for 5 minutes to obtain a mordant bath. Then soak the dyed pretreated silk thread in the prepared mordant dyeing bath, raise the temperature of the mordant dyeing bath to 40°C, keep it warm for 50 minutes, and then carry out conventional soaping and water washing on the mordant treated silk thread, and dry it to obtain dyed...

Embodiment 2

[0044] a Weigh 1 kg of silk thread with a linear density specification of 17 / 19D, then weigh 100 g of Keshu natural dye, add the weighed natural dye to 50 kg of distilled water and dissolve for 10 minutes to obtain a dyeing solution. Then soak the silk threads in the prepared dyeing solution, raise the temperature of the dyeing solution to 50° C., keep it warm for 10 minutes, then raise the temperature of the dyeing solution to 80° C., keep it warm for 70 minutes, and obtain the dyed pretreated silk thread.

[0045] b prepare 50kg concentration of 1g / L acetic acid aqueous solution, then add 500g FeSO 4 Add to acetic acid aqueous solution and dissolve for 10 minutes to obtain a mordant bath. Then soak the dyed pretreated silk thread in the prepared mordant dyeing bath, raise the temperature of the mordant dyeing bath to 50°C, keep it warm for 40 minutes, and then carry out conventional soaping and water washing on the mordant treated silk thread, and then dry it to obtain dyed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com