Catalyst for preparing n-(1,4-dimethylpentyl)-p-phenylenediamine, its preparation method and n-(1,4-dimethylpentyl)-p-phenylenediamine preparation method

A technology of dimethylpentyl and p-phenylenediamine, which is applied in the field of preparation of N--p-phenylenediamine, can solve the problems such as complex synthetic methods of p-phenylenediamine, and achieve easy operation, high purity and conversion rate, React Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

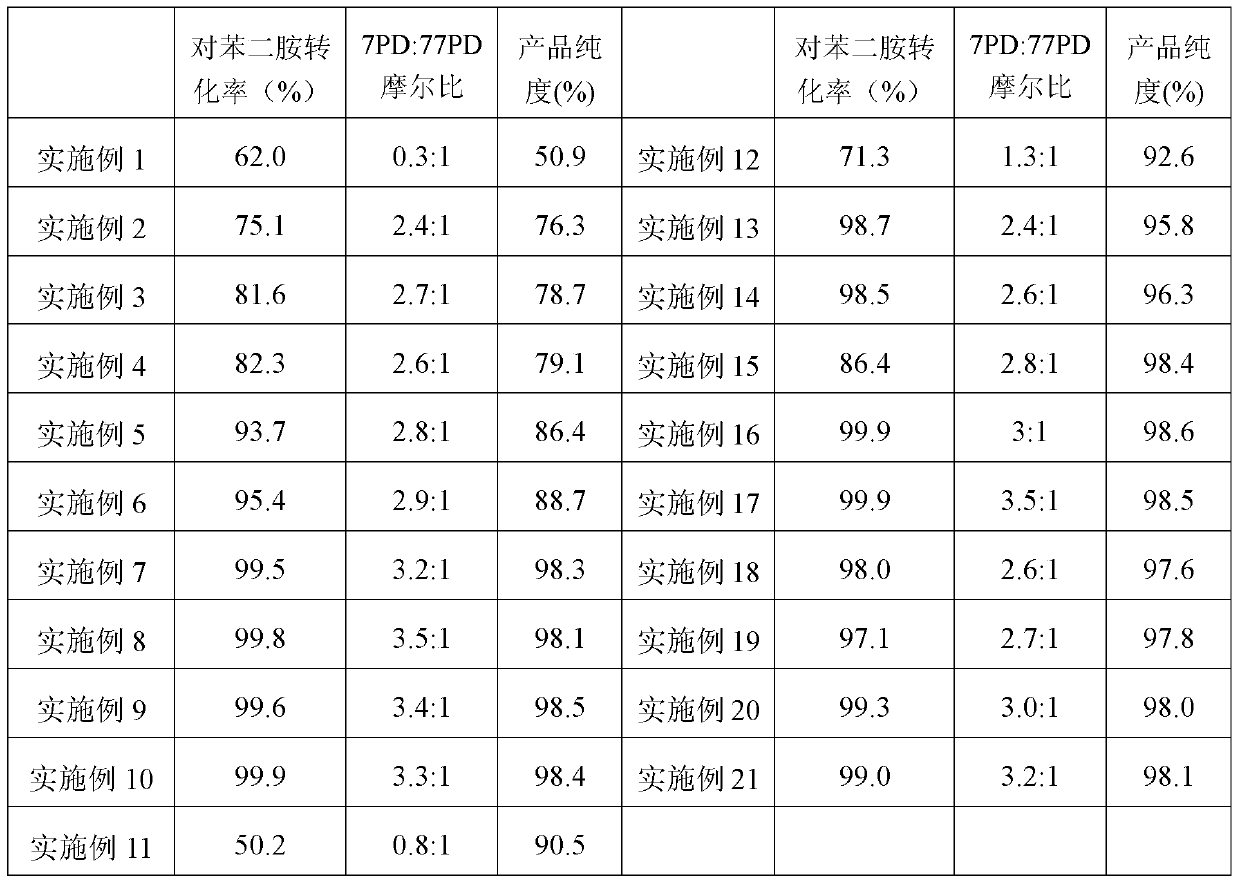

Examples

preparation example Construction

[0030] In addition, the present invention also provides a method for preparing a catalyst for preparing N-(1,4-dimethylpentyl)-p-phenylenediamine, which includes: impregnating the active component with a soluble salt solution, roasting supported on the catalyst carrier to form a catalyst. The catalyst prepared by the method has high dispersibility of the active component in the catalyst carrier, which is beneficial to improving the conversion rate of p-phenylenediamine.

[0031] In a preferred embodiment, the above preparation method includes the following steps: S1, impregnating the catalyst carrier in a mixed solution containing soluble salts of copper, nickel, chromium, palladium and zinc, and then filtering to obtain the first filtrate ; S2, roasting the first filtrate to obtain a catalyst.

[0032] The catalyst carrier is placed in a mixed solution formed by soluble salts of copper, nickel, chromium, palladium and zinc, and these soluble salts can be adsorbed on the cata...

Embodiment 1

[0048] Preparation of catalyst:

[0049] After the alumina and activated carbon were washed with methanol three times, they were dried in a vacuum of 0.05 MPa and 80°C for 5 hours, and were ground into particles with a particle size of 600 mesh. Cu(NO 3 ) 2 , Zn(NO 3 ) 2 , Cr(NO 3 ) 3 、NiNO 3 and PdCl 2 Dissolve in water to obtain a mixed solution; then place the above-mentioned mixture of alumina and activated carbon as a catalyst carrier in the mixed solution, mix and stir for 1 hour, and then let stand for 8 hours. After the impregnation, filter, wash the first filtrate with water for 3 times, and dry at 0.05 MPa and 80° C. for 10 h to constant weight. Continue to raise the temperature to 800° C., and after calcining for 4 hours under nitrogen atmosphere, the catalyst is obtained. The composition of this catalyst is as follows (by weight percentage, unit is %):

[0050] CuO Ni 2 o 3

ZnO Cr 2 o 3

PdCl 2

al 2 o 3

activated ...

Embodiment 2

[0056] Preparation of catalyst:

[0057] After the alumina and activated carbon were washed with methanol three times, they were dried in a vacuum of 0.05 MPa and 80°C for 5 hours, and were ground into particles with a particle size of 600 mesh. Cu(NO 3 ) 2 , Zn(NO 3 ) 2 , Cr(NO 3 ) 3 、NiNO 3 and PdCl 2 Dissolve in water to obtain a mixed solution; then place the above-mentioned mixture of alumina and activated carbon as a catalyst carrier in the mixed solution, mix and stir for 1 hour, and then let stand for 8 hours. After the impregnation, filter, wash the first filtrate with water for 3 times, and dry at 0.05 MPa and 80° C. for 10 h to constant weight. Continue to raise the temperature to 800° C., and after calcining for 4 hours under nitrogen atmosphere, the catalyst is obtained. The composition of this catalyst is as follows (by weight percentage, unit is %):

[0058] CuO Ni 2 o 3

ZnO Cr 2 o 3

PdCl 2

Al 2 o 3

activated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com