Ultrathin lithium ion battery current collector, ultrathin lithium ion battery and preparation method

An ion battery and current collector technology, applied in the manufacture of electrolyte batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of low durability, poor weldability, increased labor costs, etc., to avoid electrochemical pitting corrosion or Effects of stress corrosion, increased strength and durability, and low labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

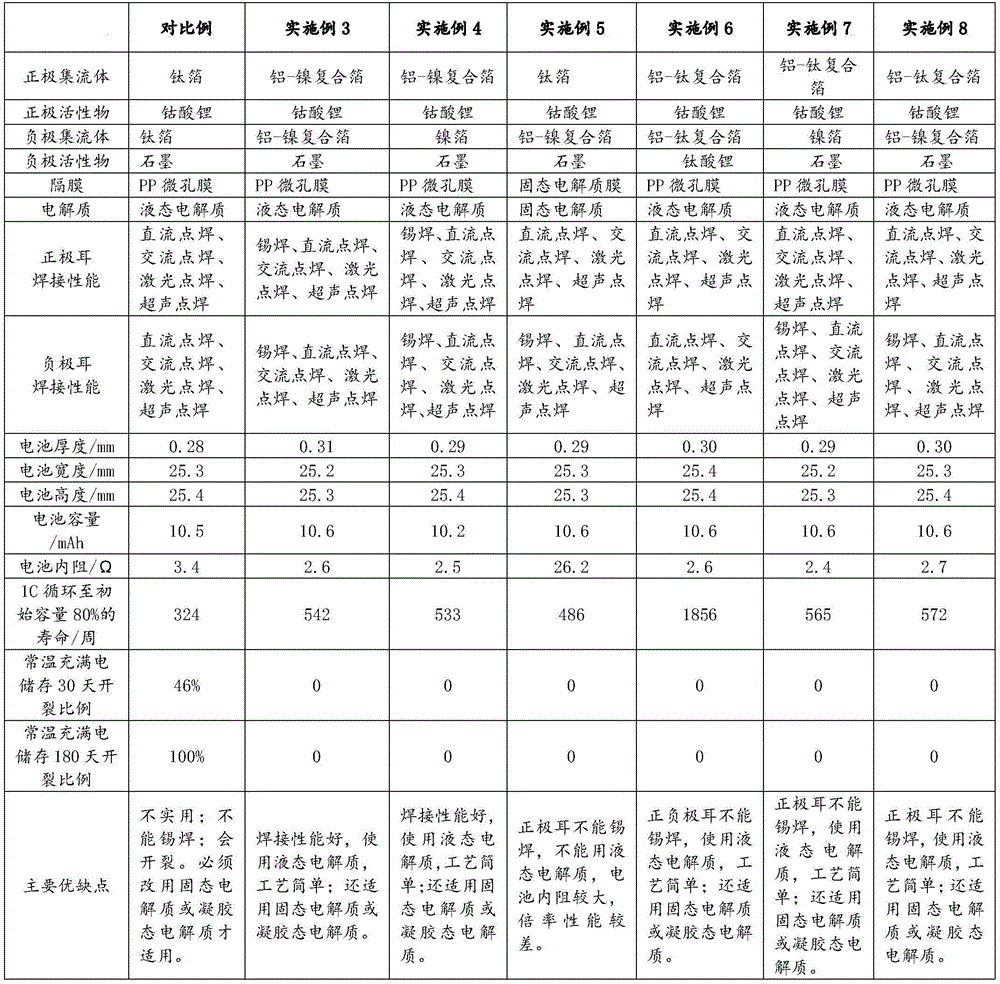

[0043] Embodiment 1: Metal composite foil with easy-soldering layer

[0044] The ultra-thin lithium ion battery current collector of this embodiment, the current collector doubles as the packaging film of the ultra-thin lithium ion battery, the current collector is a metal composite foil, and the metal composite foil at least includes an easy-soldering material made of an easy-to-solder material. layer and a current-collecting conductive layer, the current-collecting conductive layer is one of aluminum layer, aluminum alloy layer, titanium layer, titanium alloy layer or chromium layer; the easy-soldering layer and the current-collecting conductive layer are combined into one.

[0045] The easy-soldering layer is one of nickel layer, nickel alloy layer, copper layer, copper alloy layer, silver layer, silver alloy layer or iron layer, iron alloy layer or stainless steel foil; the metal composite foil is: aluminum- Nickel metal composite foil, aluminum-nickel alloy metal composit...

specific Embodiment approach 2

[0058] Embodiment 2: metal composite foil with corrosion-resistant conductive layer

[0059] The ultra-thin lithium-ion battery current collector of this embodiment, the current collector is also used as the packaging film of the ultra-thin lithium-ion battery, the current collector is a metal composite foil, and the metal composite foil at least includes a corrosion-resistant conductive layer and a reinforced composite layer. The composite layer is one of titanium foil or titanium alloy layer, chromium layer, aluminum layer or aluminum alloy layer, and the corrosion-resistant conductive layer is aluminum layer or aluminum alloy layer; the corrosion-resistant conductive layer and the current-collecting conductive layer are combined into one; the The metal composite foils are: titanium-aluminum metal composite foil, titanium-aluminum alloy metal composite foil, titanium alloy-aluminum metal composite foil, titanium alloy-aluminum alloy metal composite foil, chromium-aluminum met...

specific Embodiment approach 3

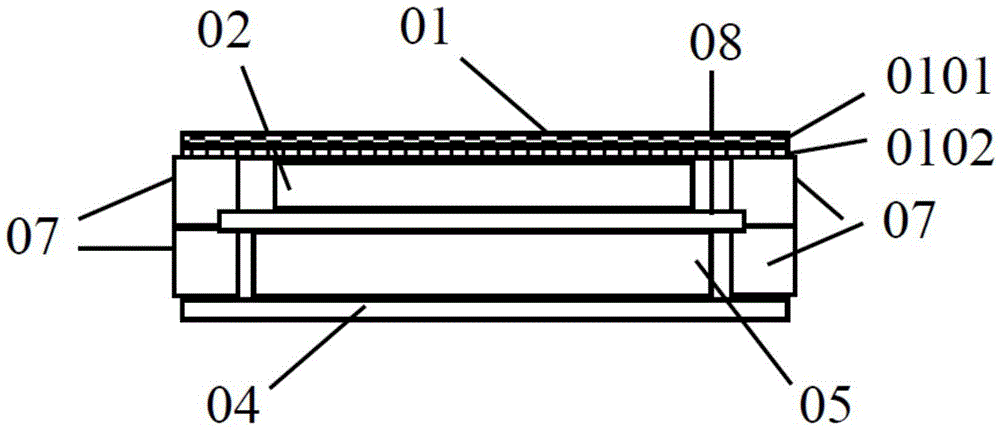

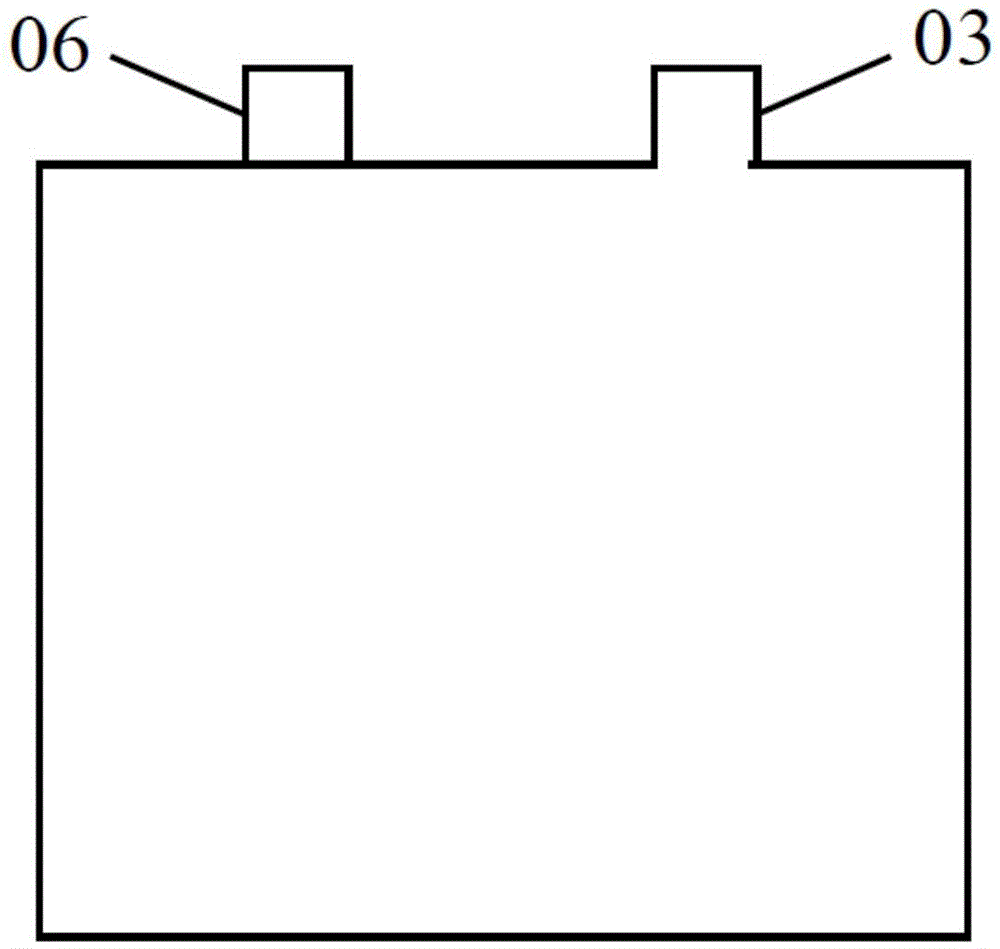

[0069] Specific implementation method three: both the positive and negative electrodes use a metal composite foil battery with an easy-to-solder layer

[0070]This embodiment provides an ultra-thin lithium-ion battery using the current collector described in Embodiment 1, comprising a positive electrode sheet, a negative electrode sheet, an electrolyte, a separator and a hot-melt rubber ring, and the separator separates the positive electrode sheet and the negative electrode sheet, Electrolyte is filled between the diaphragm and the positive electrode sheet and the negative electrode sheet. The positive electrode sheet includes a positive electrode collector and a positive electrode paste. The positive electrode paste is bonded to the positive electrode collector. The negative electrode sheet includes a negative electrode collector and a negative electrode paste. The negative electrode paste is bonded to the negative electrode collector Above, the current collector is also used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com