Polysulfone resin and semi-aromatic nylon alloy, and preparation method thereof

A technology of semi-aromatic nylon and polysulfone resin, which is applied to the alloy of polysulfone resin and semi-aromatic nylon and the field of preparation thereof, can solve the problems of unsatisfactory, poor antistatic performance and flame retardant performance, and high temperature resistance of nylon alloy. , stiffness and low impact strength, etc., to achieve the effect of high production efficiency, stable product quality, antistatic and flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

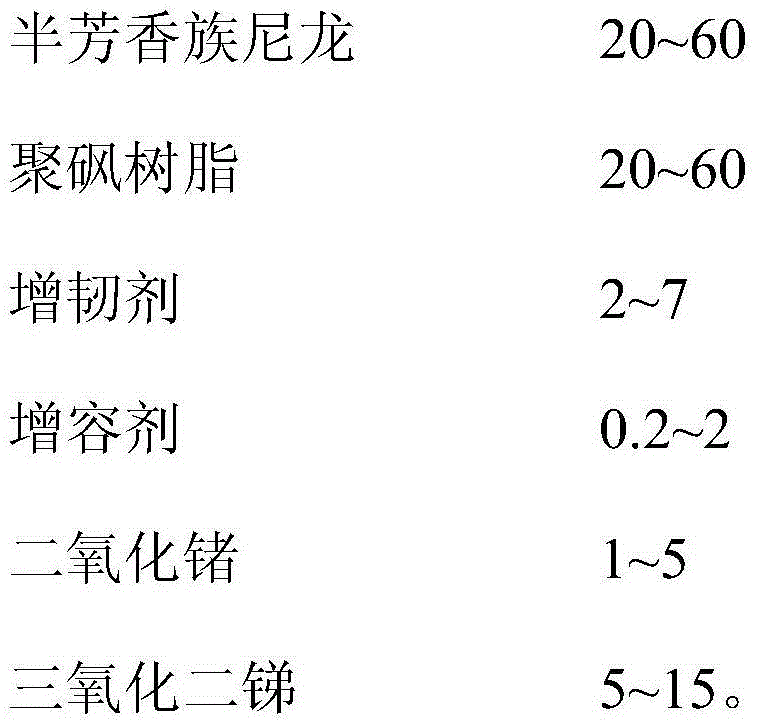

[0030] An alloy of polysulfone resin and semi-aromatic nylon, which is mainly prepared from the following raw materials in parts by weight:

[0031]

[0032]

[0033] The semi-aromatic nylon includes PA6T.

[0034] The polysulfone resin includes polyphenylene ether sulfone.

[0035] The compatibilizer includes maleic acid.

[0036] The toughening agent includes styrene-butadiene-styrene triblock copolymer.

[0037] A method for preparing an alloy of polysulfone resin and semiaromatic nylon as described above, comprising the following steps:

[0038] (1) mixing each raw material of formula quantity to form a mixture;

[0039] (2) Put the mixture into a twin-screw extruder, blend at 250-350° C., extrude, and granulate to obtain an alloy of polysulfone resin and semi-aromatic nylon.

Embodiment 2

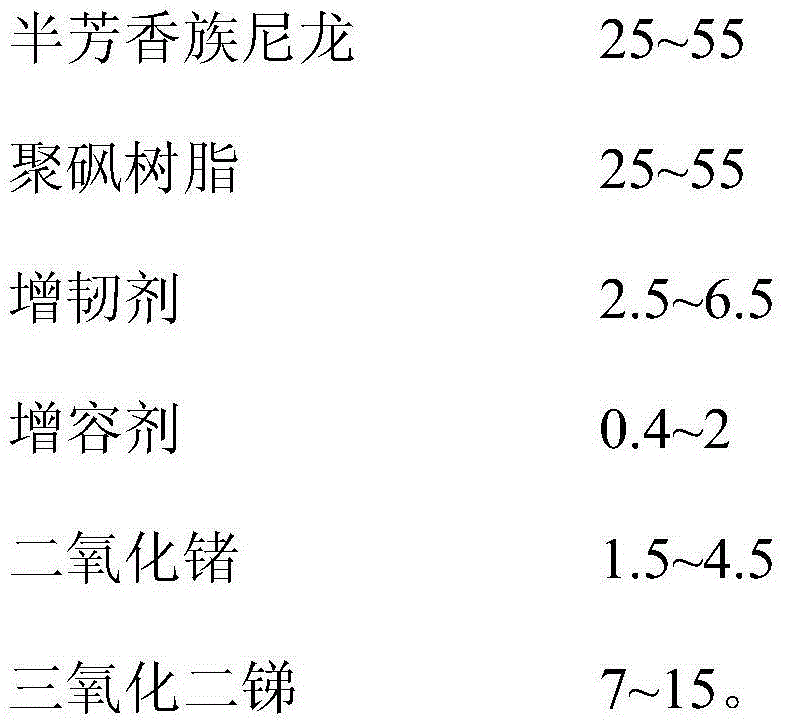

[0041] An alloy of polysulfone resin and semi-aromatic nylon, which is mainly prepared from the following raw materials in parts by weight:

[0042]

[0043] The semi-aromatic nylon includes PA9T.

[0044] The polysulfone resin includes polyethersulfoneketone.

[0045] The compatibilizer includes glycidyl acrylate.

[0046] The toughening agent includes a styrene / hydrogenated isoprene block copolymer.

[0047] A method for preparing an alloy of polysulfone resin and semiaromatic nylon as described above, comprising the following steps:

[0048] (1) mixing each raw material of formula quantity to form a mixture;

[0049] (2) Put the mixture into a twin-screw extruder, blend at 250-350° C., extrude, and granulate to obtain an alloy of polysulfone resin and semi-aromatic nylon.

Embodiment 3

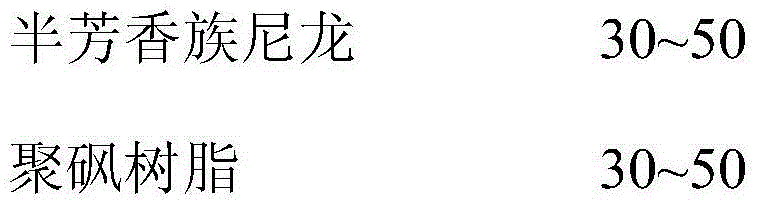

[0051] An alloy of polysulfone resin and semi-aromatic nylon, which is mainly prepared from the following raw materials in parts by weight:

[0052]

[0053] The semi-aromatic nylon includes PA7T.

[0054] The polysulfone resin includes biphenyl polyether sulfone, polyether sulfone ketone and polyphenylene sulfone.

[0055] The compatibilizer includes maleic anhydride.

[0056] The tougheners include mixtures of styrene / hydrogenated isoprene block copolymers and hydrogenated styrene-butadiene-styrene triblock copolymers.

[0057] A method for preparing an alloy of polysulfone resin and semiaromatic nylon as described above, comprising the following steps:

[0058] (1) mixing each raw material of formula quantity to form a mixture;

[0059] (2) Put the mixture into a twin-screw extruder, blend at 250-350° C., extrude, and granulate to obtain an alloy of polysulfone resin and semi-aromatic nylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com