a sio 2 Brazing method for ceramic matrix composites

A composite material and brazing method technology, which is applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve the problems of poor wettability of active brazing filler metals, and it is difficult to achieve high-quality connection and effective connection of composite components. Achieve the effect of easy industrial production, low cost, high quality connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

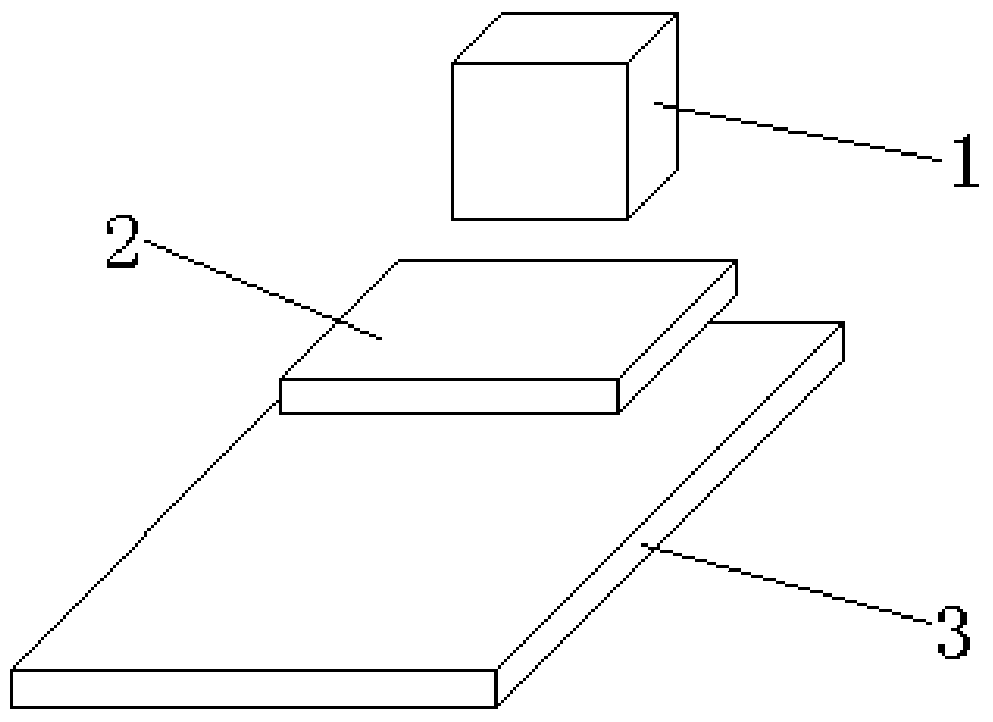

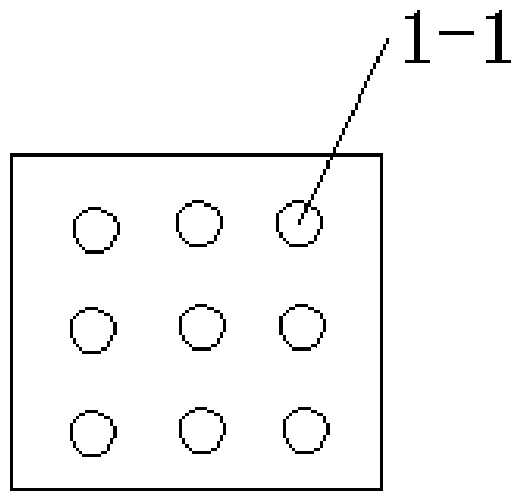

[0019] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment specifically, a kind of SiO described in this embodiment 2 The brazing method of the ceramic matrix composite material is specifically carried out according to the following steps:

[0020] 1. SiO 2 The ceramic matrix composite material and the metal material were polished with sandpaper respectively, and then cleaned with acetone for 10-20 minutes to obtain the cleaned SiO 2 Ceramic matrix composites and cleaned metal materials;

[0021] 2. SiO after cleaning with a punching machine 2 Blind holes are drilled on the surface of the ceramic matrix composite material to be welded, and the blind holes are evenly distributed on the SiO 2 On the surface of the ceramic matrix composite material to be welded, the diameter of the blind hole is 0.5 mm to 5 mm, the depth of the blind hole is 1 mm to 10 mm, and the distance between the blind holes is 1.0 mm to 5.0 mm, and the SiO with a por...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the SiO described in step one 2 The ceramic matrix composite is SiO 2f / SiO 2 Composite ceramics, SiO 2f / Al 2 o 3 Composite ceramics, quartz glass ceramics or SiO 2 -BN composite ceramics. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031]Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the metal material described in step 1 is Nb, TC4 titanium alloy or Invar alloy. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com