Low-potential-gradient voltage-sensitive-capacitance dual-functional titanium dioxide ceramic material and preparing method thereof

A technology of titanium dioxide and ceramic materials, which is applied in the field of low-potential gradient varistor-capacitance dual-functional titanium dioxide ceramic materials and its preparation, can solve the problems of increasing production costs and increasing the process, achieving small potential gradients, simplifying the sintering process, and comprehensive good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

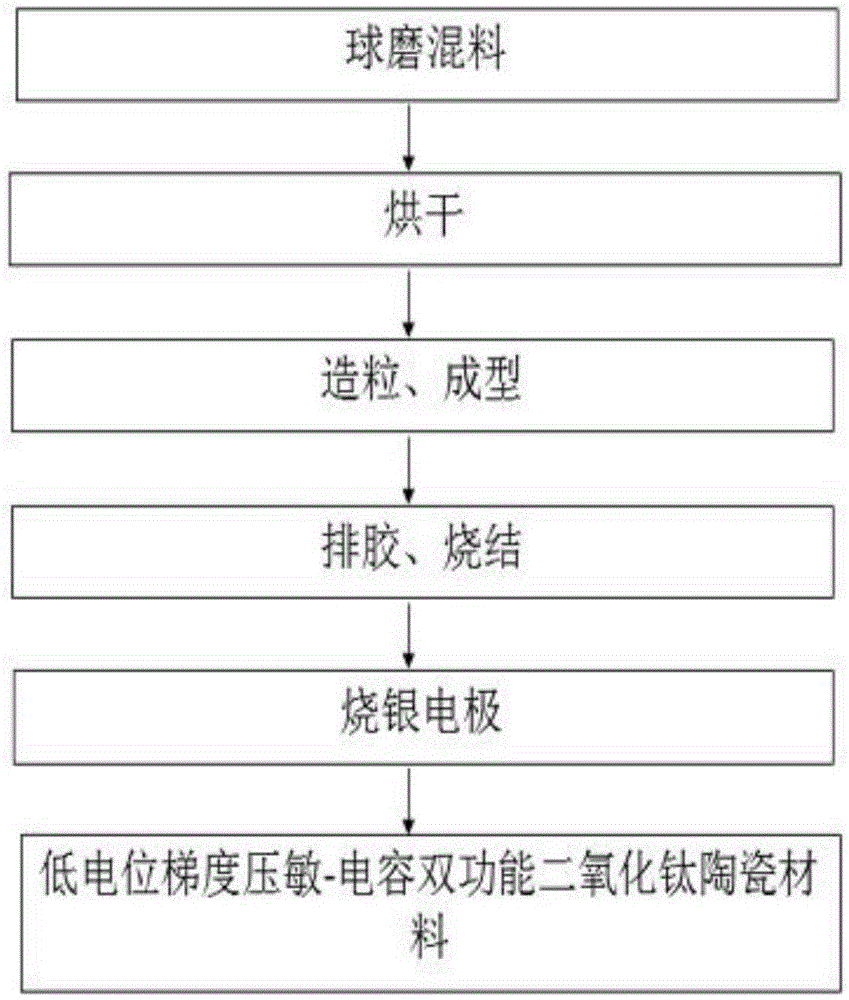

Method used

Image

Examples

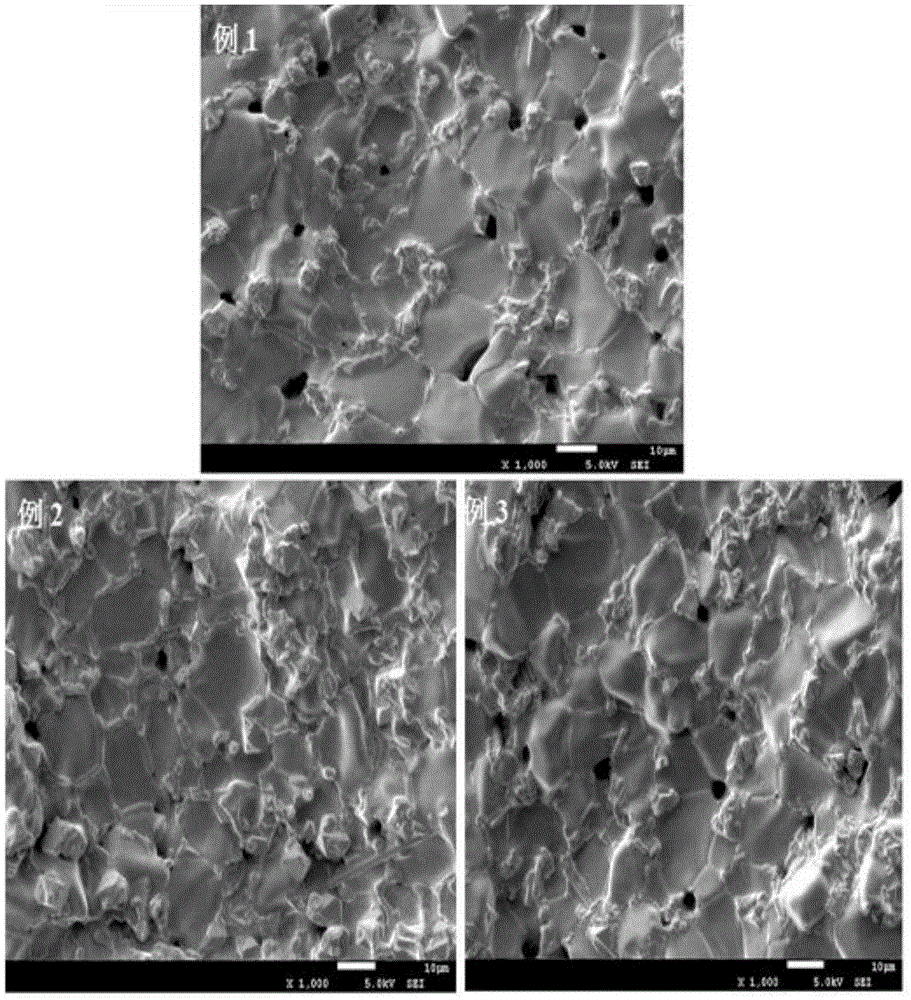

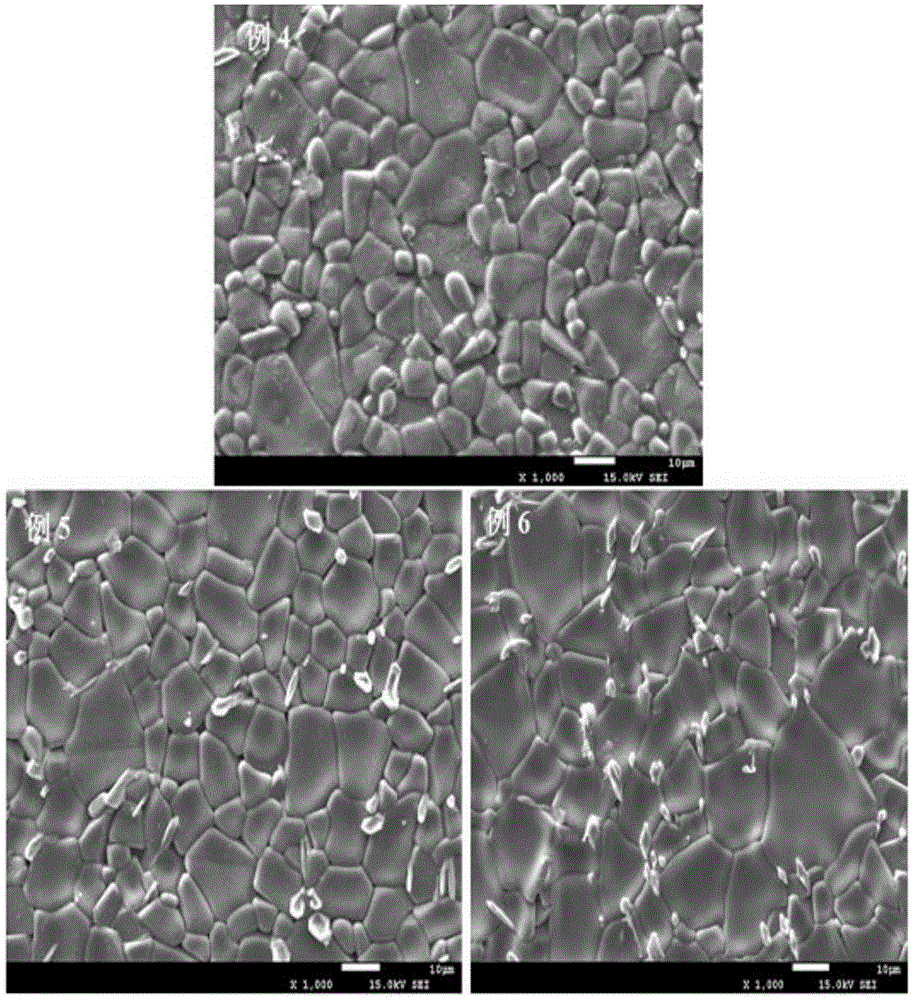

Embodiment 1

[0027] Micron-sized powder according to 99.0mol%TiO 2 , Nb 2 o 5 0.6mol%, 0.3mol%SiO 2 , 0.1mol%Sm 2 o 3 Proportional weighing, after mixing, add to the agate grinding tank, add absolute ethanol as a lubricant, wet ball mill until the powder is fully mixed, and dry the fully mixed powder at 60°C. Add 5.wt% polyvinyl alcohol (PVA) as a binder, and dry press it into a green body. The green body is placed in the furnace and slowly heated to 400°C for 1 hour for debinding treatment, then heated to 1450°C for 2 hours, then cooled to room temperature with the furnace, and kept at 870°C for 1 hour to burn silver electrodes. The resulting titanium dioxide ceramics were tested for performance, and the potential gradient (E 1mA ) is 9.3V / mm, nonlinear coefficient (α) is 2.74, relative permittivity (ε r ) is 4.9 x 10 4 , the loss angle (tanδ) is 0.57.

Embodiment 2

[0029] Micron-sized powder according to 99.0mol%TiO 2 , 0.5%molNb 2 o 5 , 0.2mol%SiO 2 , 0.3%molSm 2 o 3 Proportional weighing. After mixing, put it into the agate grinding tank, add absolute ethanol as lubricant, wet ball mill until the powder is fully mixed, and dry the fully mixed powder at 70°C. Add 6.wt% polyvinyl alcohol (PVA) as a binder, and dry press it into a green body. The green body is placed in the furnace and slowly heated to 400°C for 1 hour for debinding treatment, then heated to 1450°C for 2 hours, then cooled to room temperature with the furnace, and kept at 870°C for 1 hour to burn silver electrodes. The resulting titanium dioxide ceramics were tested for performance, and the voltage gradient was (E 1mA ) 13.1V / mm, nonlinear coefficient (α) is 4.10, relative permittivity (ε r ) is 9.5 x 10 4 , the loss angle (tanδ) is 0.52.

Embodiment 3

[0031] Micron-sized powder according to 99.1%molTiO 2 , 0.6%molNb 2 o 5 , 0.1%molSiO 2 , 0.2%molSm 2 o 3 Proportional weighing. After mixing, put it into the agate grinding tank, add acetone as lubricant, wet ball mill until the powder is fully mixed, and dry the fully mixed powder at 75°C. Add 7.wt% polyvinyl alcohol (PVA) as a binder, and dry press it into a green body. The green body is placed in the furnace and slowly heated to 400°C for 1.5 hours for debinding treatment, then heated to 1350°C for 4 hours of heat preservation and sintering, then cooled to room temperature with the furnace, and kept at 870°C for 1 hour to burn silver electrodes. The resulting titanium dioxide ceramics were tested for performance, and the potential gradient (E 1mA ) is 9.8V / mm, the nonlinear coefficient (α) is 4.13, and the relative permittivity (ε r ) is 9.0 x 10 4 , the loss angle (tanδ) is 0.45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potential gradient | aaaaa | aaaaa |

| Voltage gradient | aaaaa | aaaaa |

| Potential gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com