ZnO-Bi2O3-based low-voltage voltage-sensitive ceramic capable of being sintered at low temperature and preparation method thereof

A zno-bi2o3, low-temperature sintering technology, applied in the direction of varistor, varistor core, etc., can solve the problems of high sintering temperature, high voltage gradient, internal stress, etc. Linear coefficient, effect of increasing grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: A low-temperature sintered highly nonlinear ZnO-Bi 2 o 3 Low-voltage varistor-based ceramics and a preparation method thereof.

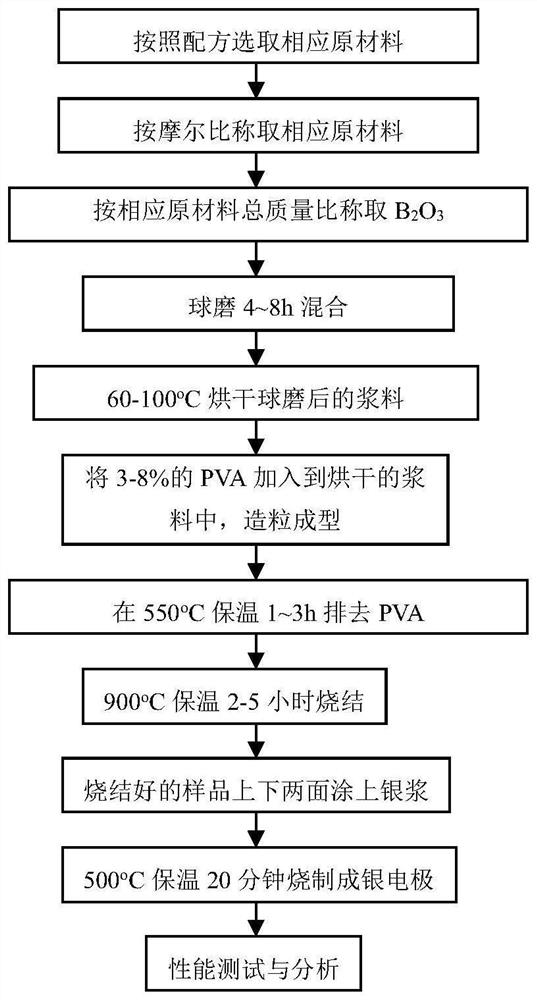

[0037] according to figure 1 The process flow shown, the preparation of undoped B 2 o 3 and ZnO-Bi with x=1 2 o 3 Base varistor ceramics, the specific steps are as follows:

[0038] (1) Weigh ZnO and Bi according to the molar ratio of chemical composition 2 o 3 、TiO 2 、Co 2 o 3 and MnO 2 raw material;

[0039] (2) ZnO-Bi weighed from (1) 2 o 3 In the initial raw material of base varistor ceramics, add the B of x wt% of the total mass in (1) respectively 2 o 3 raw material, where x=1;

[0040] (3) Using absolute ethanol as a solvent, ball milling and mixing for 8 hours;

[0041] (4) Put the ball-milled slurry into an oven to dry at 60°C;

[0042] (5) adding 3wt% PVA binder to the dried powder, and pressing it into a thin disc with a diameter of 12 mm and a thickness of 0.8 to 1.5 mm;

[0043] (6) Insulate the pres...

Embodiment 2

[0052] Example 2: A low-temperature sintered highly nonlinear ZnO-Bi 2 o 3 Low-voltage varistor-based ceramics and a preparation method thereof.

[0053] according to figure 1 The process flow shown, the ZnO-Bi of preparation x=2 2 o 3 Base varistor ceramics, the specific steps are as follows:

[0054] (1) Weigh ZnO and Bi according to the molar ratio of chemical composition 2 o 3 、TiO 2 、Co 2 o 3 and MnO 2 raw material;

[0055] (2) ZnO-Bi weighed from (1) 2 o 3 In the initial raw material of base varistor ceramics, add the B of x wt% of the total mass in (1) respectively 2 o 3 raw material, where x=2;

[0056] (3) Using deionized water as a solvent, ball milling and mixing for 8 hours;

[0057] (4) put the ball-milled slurry into an oven and dry at 100°C;

[0058] (5) adding 3wt% PVA binder to the dried powder, pressing it into a thin disc with a diameter of 12mm and a thickness of 0.8-1.5mm;

[0059] (6) Insulate the pressed thin disc at 550° C. for 3 hour...

Embodiment 3

[0068] Example 3: A low-temperature sintered highly nonlinear ZnO-Bi 2 o 3 Low-voltage varistor-based ceramics and a preparation method thereof.

[0069] according to figure 1 The process flow shown, the ZnO-Bi of preparation x=3 2 o 3 Base varistor ceramics, the specific steps are as follows:

[0070] (1) Weigh ZnO and Bi according to the molar ratio of chemical composition 2 o 3 、TiO 2 、Co 2 o 3 and MnO 2 raw material;

[0071] (2) ZnO-Bi weighed from (1) 2 o 3 In the initial raw material of base varistor ceramics, add the B of x wt% of the total mass in (1) respectively 2 o 3 Raw materials, where x=3;

[0072] (3) Using deionized water as a solvent, ball milling and mixing for 8 hours;

[0073] (4) Put the ball-milled slurry into an oven to dry at 80°C;

[0074](5) adding 3wt% PVA binder to the dried powder, pressing it into a thin disc with a diameter of 12mm and a thickness of 0.8-1.5mm;

[0075] (6) Insulate the pressed thin disc at 550° C. for 2 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com