Preparation method of hydrodeoxygenation catalyst with high hydrothermal/mechanical stability

A technology of mechanical stability and deoxidation catalyst, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of poor catalyst activity and mechanical stability, and achieve high water content. The effect of thermal/mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

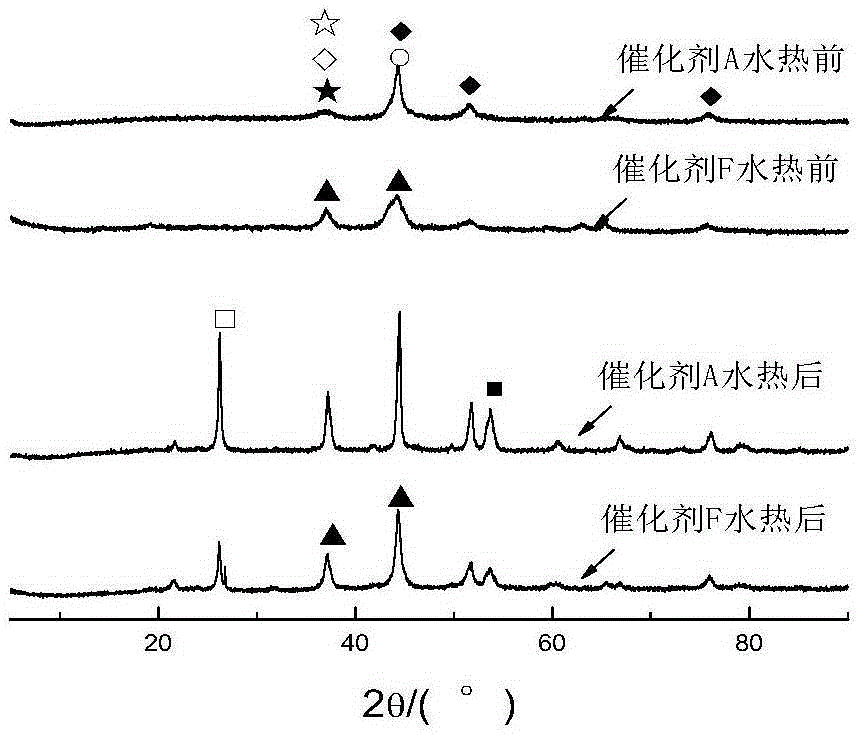

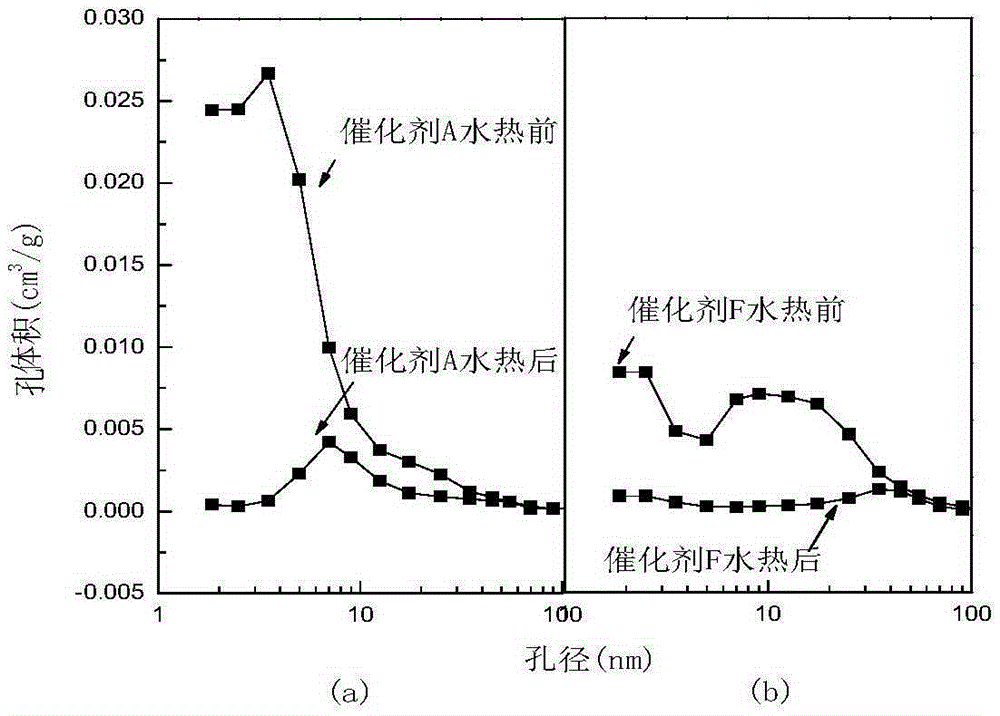

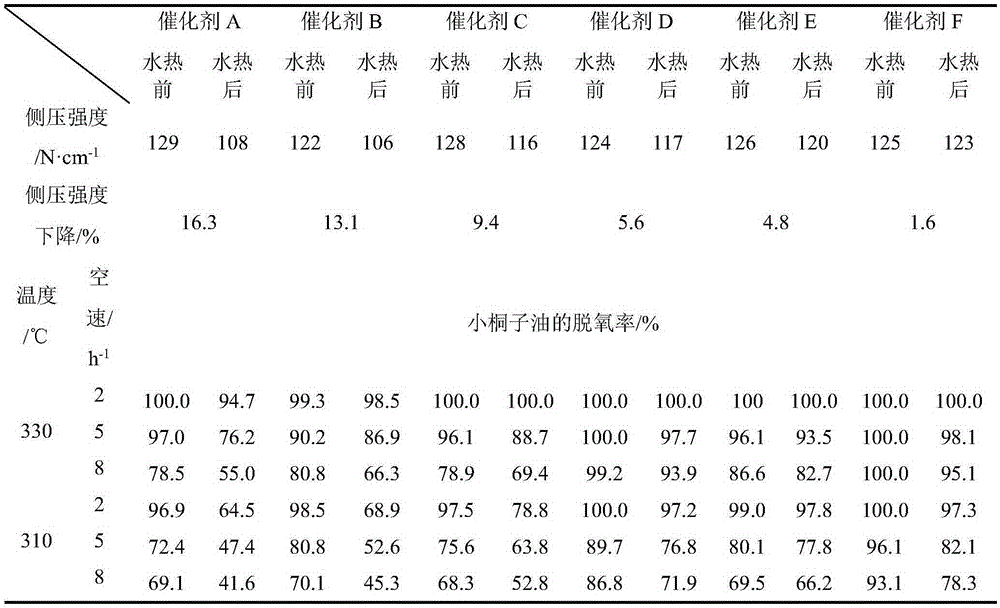

[0024] The preparation of comparative example catalyst A:

[0025] MoNi composite oxide powder was prepared according to the patent "Preparation method of large-pore bulk Ni-Mo hydrodeoxygenation catalyst" (application number: 201510173213.9). Weigh a certain amount of Mo(NO 3 ) 3 ·5H 2 O, Ni(NO 3 ) 2 ·6H 2 O, citric acid, molar ratio is Mo: Ni=0.2, molar ratio (Mo+Ni): citric acid=1.5 (wherein, the meaning of " (Mo+Ni) mol " is the molar sum of molybdenum element and nickel element ), respectively dissolved in a certain volume fraction of 50% ethanol aqueous solution, the total consumption of ethanol aqueous solution is 500mL / (Ni+Mo)mol, the above solutions are mixed evenly and the pH value of the mixed solution is regulated by 27% ammonia water with a mass fraction of 5. The mixture was magnetically stirred in a 70°C water bath until a sol was formed, ultrasonically oscillated for 25 minutes, aged at room temperature for 4 hours, and dried at 120°C to obtain a xerogel...

Embodiment 1

[0028] Weigh a certain amount of (NH 4 ) 6 Mo 7 o 24 4H 2 O, NiSO 4 ·6H 2 O, oxalic acid, molar ratio is Mo:Ni=0.4, molar ratio (Mo+Ni): oxalic acid=1.2 (wherein, the implication of " (Mo+Ni) mol " is the molar sum of molybdenum element and nickel element), Dissolve in a certain amount of aqueous ethanol solution with a volume fraction of 50%, the total consumption of the aqueous ethanol solution is 600mL / (Ni+Mo)mol, mix the above solutions evenly and adjust the pH value of the mixed solution to 4 with a mass fraction of 27% ammonia, The mixture was magnetically stirred in an 80°C water bath until a sol was formed, ultrasonically oscillated for 15 min, aged at room temperature for 3.5 h, and dried at 120°C to obtain a xerogel. The xerogel was calcined at 300°C for 3h in a nitrogen atmosphere in a tube furnace, and at 550°C for 4h in an air atmosphere in a muffle furnace to obtain MoNi composite oxide powder B.

Embodiment 2

[0030] Weigh a certain amount of H in proportion 2 MoO 4 ·H 2 O, NiCl 2 ·6H 2 O, glycolic acid, molar ratio is Mo: Ni=0.6, molar ratio (Mo+Ni): glycolic acid=1 (wherein, the implication of " (Mo+Ni) mol " is the sum of the molar number of molybdenum element and nickel element ), respectively dissolved in a certain volume fraction of 50% ethanol aqueous solution, the total consumption of ethanol aqueous solution is 700mL / (Ni+Mo)mol, the above solutions are mixed evenly and the pH value of the mixed solution is regulated by 27% ammonia water with mass fraction 3. The mixture was magnetically stirred in a 90°C water bath until a sol was formed, ultrasonically oscillated for 30min, aged at room temperature for 3h, and dried at 120°C to obtain a xerogel. The xerogel was calcined at 200°C for 4h in a nitrogen atmosphere in a tube furnace, and at 600°C for 2h in an air atmosphere in a muffle furnace to obtain MoNi composite oxide powder C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com