Precious metal recovery device for waste liquid incineration

A precious metal and waste liquid technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of incomplete incineration treatment and insufficient combustion, and achieve the effect of saving manufacturing costs, saving fuel, and strong volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

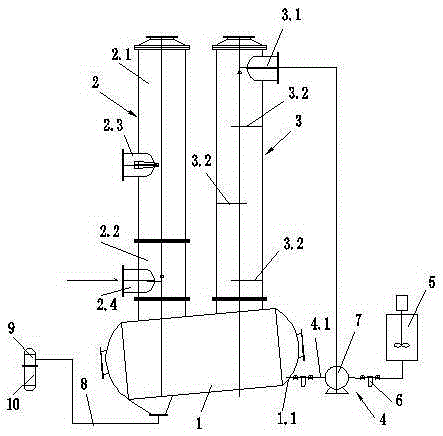

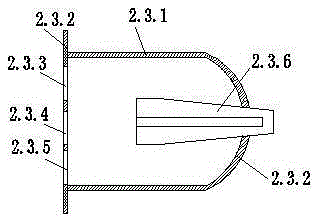

[0013] Embodiment 1: waste liquid incineration recovery precious metal device, comprising a storage tank 1 that is discharged horizontally and inclined upwards at 15 degrees, and a vertically upward incineration tower 2 and a scrubber 3 are arranged side by side on the top side wall of the storage tank 1, and the incineration tower 2 and the bottom end of scrubber 3 are connected with the storage tank 1. The incineration tower 2 includes a tower tube, the top of which is sealed. The wall is provided with a waste liquid inlet pipe 2.3, the side wall of the quenching section 2.2 is provided with an atomizing spray pipe 2.4, the gas scrubber 3 includes a tower, and the side wall near the top of the tower is provided with a circulating water inlet 3.1, and the storage tank 1 is upward The bottom of the inclined end is provided with a dosing port 1.1, and the dosing port 1.1 is connected to the dosing system 4. The dosing system 4 includes a dosing pipeline 4.1 connected to the dosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com