Diisocyanate, polyurethane prepolymer, preparation method of polyurethane prepolymer and waterborne polyurethane

A polyurethane prepolymer and diisocyanate technology, applied in the field of polyurethane, can solve the problems of poor molecular chain hydrophilicity, poor storage stability, and low proportion of soft segments, and achieve good hydrophilicity, high stability, and high proportion of soft segments. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a kind of preparation method of polyurethane prepolymer, comprises the following steps:

[0050] The diisocyanate described in the above technical scheme is mixed with the hydroxyl-terminated polymer to obtain a polyurethane prepolymer;

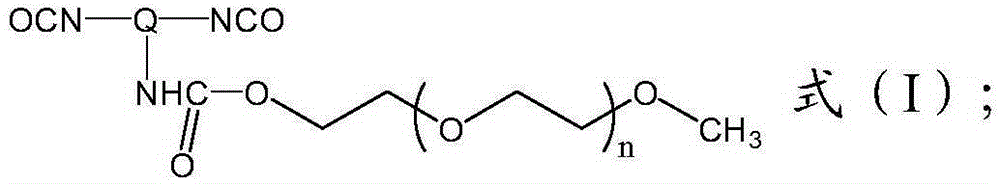

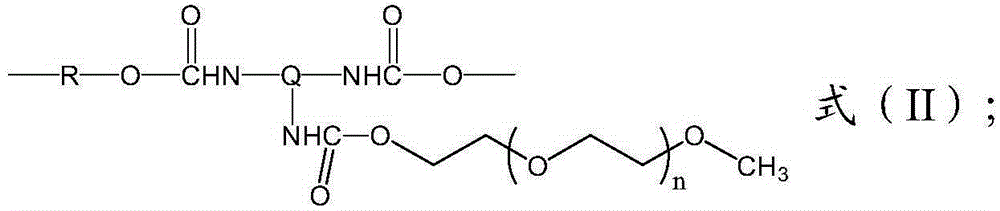

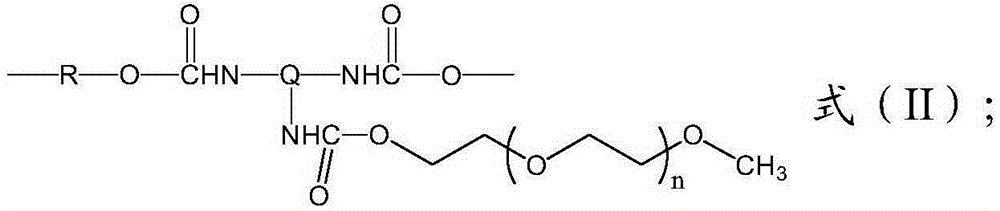

[0051] Described polyurethane prepolymer comprises the repeating unit of structure shown in formula (II):

[0052]

[0053] In the formula (II), R is the remaining residue after removing 2 terminal hydroxyl groups from the hydroxyl-terminated polymer, and Q is removing the remaining 3 residues of -N=C=O from the HDI trimer or removing 3- from the IPDI trimer. N=C=O remaining residues; n is the degree of polymerization.

[0054] In the preparation method of the polyurethane prepolymer provided by the present invention, firstly, the diisocyanate and the diol are mixed and reacted. Wherein, the glycol preferably includes one or more of polypropylene glycol, polycaprolactone glycol, polycarbonate glycol and polyte...

Embodiment 1

[0067] Preparation of diisocyanates

[0068] Add 75g (0.1mol) of polyethylene glycol monomethyl ether with a number-average molecular weight of 750 and 71g of IPDI trimer into a three-neck flask, stir and heat up to 80°C and keep it warm for 4 hours to obtain diisocyanate.

[0069] Adopt di-n-butylamine to the isocyanate group (-N=C=O) content titration test in the reaction system before and after the reaction, the test result shows: the content of the isocyanate group in the reaction system before the reaction is 5.84wt%, and the reaction system after the reaction The content of the isocyanate group in is 3.89wt%. According to the test results, it can be proved that 1 / 3 of the isocyanate groups in the IPDI trimer participate in the reaction, thus proving that the diisocyanate prepared in this embodiment has the structure of formula (I). At the same time, it can be judged according to the type of reaction raw materials that Q in the diisocyanate having the structure of formul...

Embodiment 2

[0071] Preparation of Waterborne Polyurethane

[0072] In a 250ml four-necked flask equipped with a stirrer, a condensing reflux tube, and a thermocouple, add 25g (about 0.017mol) of the diisocyanate prepared in Example 1, 24.6g (about 0.0123mol) of polytetrahydrofuran dihydrofuran with a number average molecular weight of 2000 Alcohol, 0.01 g of dibutyltin dilaurate, and react at 90° C. for 4 hours to obtain a polyurethane prepolymer.

[0073] Carry out infrared spectroscopic analysis to described polyurethane prepolymer, can draw according to the kind of infrared spectroscopic analysis result and reaction raw material: described polyurethane prepolymer is made up of repeating unit with formula (II) structure, in formula (II), R is the remaining residue after removing two terminal hydroxyl groups from polytetrahydrofuran diol, Q is a substituent of formula (b), n=17.

[0074] After the polyurethane prepolymer is cooled to 55°C, add 20g of acetone to reduce the viscosity, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com