Field effect organic solar cell and preparation method thereof

A solar cell and field effect technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low open circuit voltage, no practical value, and less light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

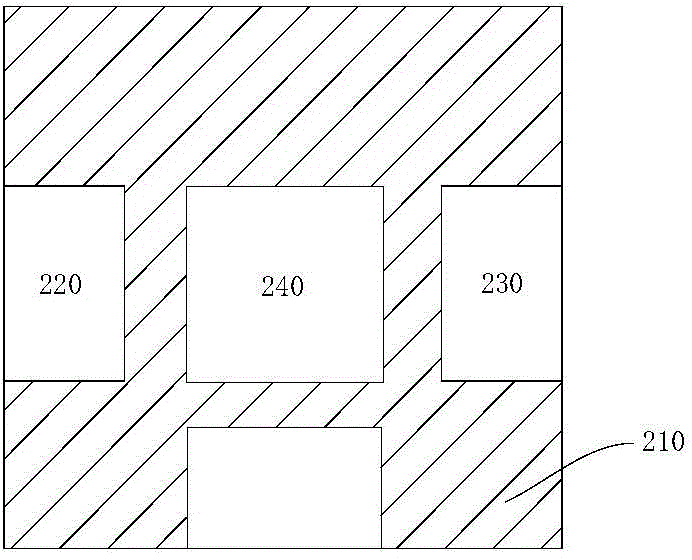

[0031] Existing field-effect organic solar cells, such as figure 1 As shown, the anode electrode 220 , cathode electrode 230 and gate electrode 240 etched on the substrate 210 are included. The gate electrode 240 is generally located at the center of the substrate 210 . This structure is not conducive to the open circuit voltage V oc , short-circuit current J sc and an increase in fill factor FF.

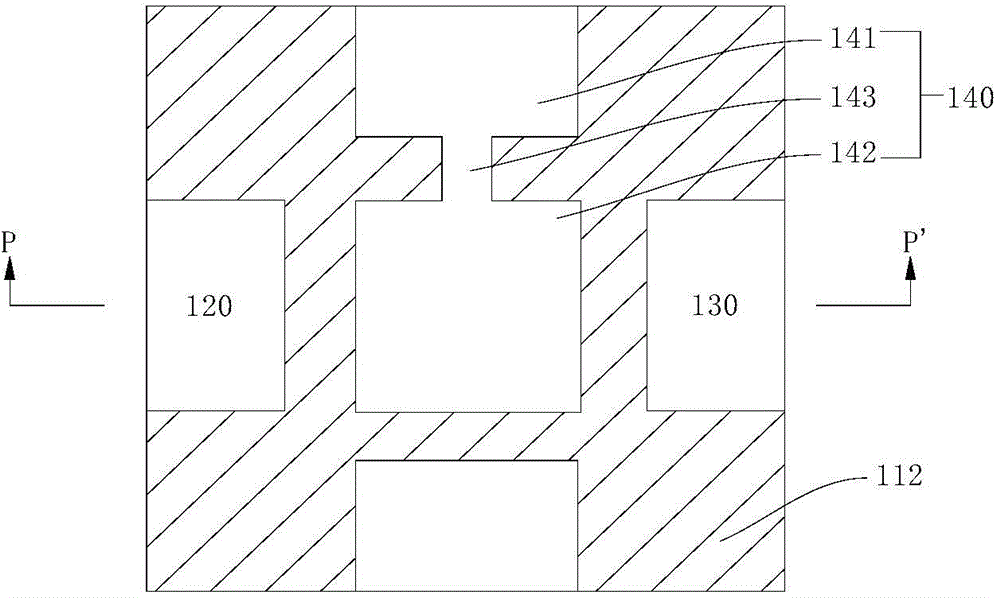

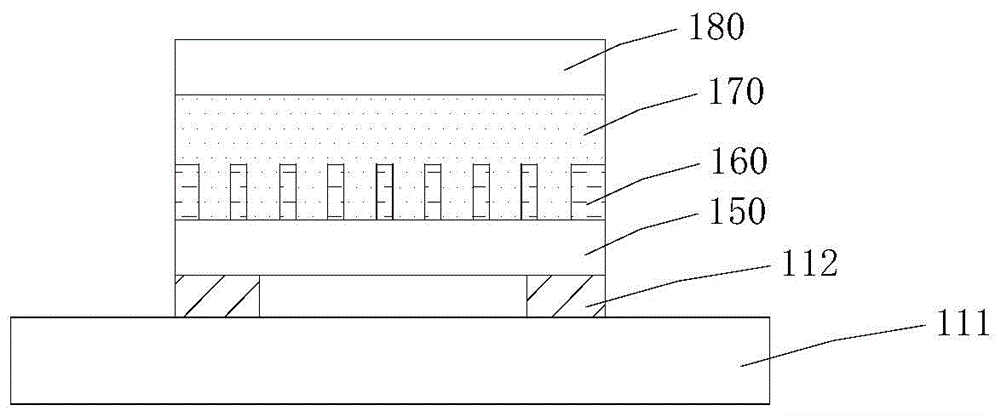

[0032] This embodiment provides a field effect organic solar cell, such as figure 2 As shown, it includes an anode electrode 120 etched on the substrate, a cathode electrode 130 and a gate electrode 140, wherein the gate electrode 140 is an improvement on the gate electrode 240 of the prior art, in order to distinguish it from the existing gate electrode 240, The present invention is named "gate electrode". Thus, the solar cell of the present invention comprises from bottom to top: substrate 110 etched with anode electrode 120 and cathode electrode 130 , dielectric layer 150 ,...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that each electrode pattern is prepared on the substrate by photolithography. Then use HCl and Zn powder to perform wet etching on the place not protected by photoresist. Alternatively, argon ion beam etching (IBE) is used to perform dry etching on the substrate without photoresist protection. An 80nm-thick Al2O3 is grown on the pair of gate electrodes by atomic deposition as the dielectric layer of the device. The PEDOT films grown on other substrates were peeled off and transferred onto the dielectric layer in ethanol.

[0049] Other procedures are identical with embodiment 1.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that each electrode pattern is etched out with the aid of a mask plate by argon ion beam etching (IBE). Spin-coat 800 nm thick polyimide (PI) on the gate electrode pair as the dielectric layer of the device. A grid pattern is etched on the dielectric layer by photolithography, and then a layer of ITO electrode material with a thickness of 200 nanometers is sputtered to prepare a grid anode layer.

[0052] Other procedures are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com