Biomass resin and preparation method of fibre oriented shaving composite board

A biomass and plant cellulose technology, applied in the direction of manufacturing tools, flat products, and other household appliances, can solve the problems of low solid content, high viscosity, hindering the application of biomass adhesives, etc., to improve the solid content, physical High mechanical properties and the effect of improving the secondary bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

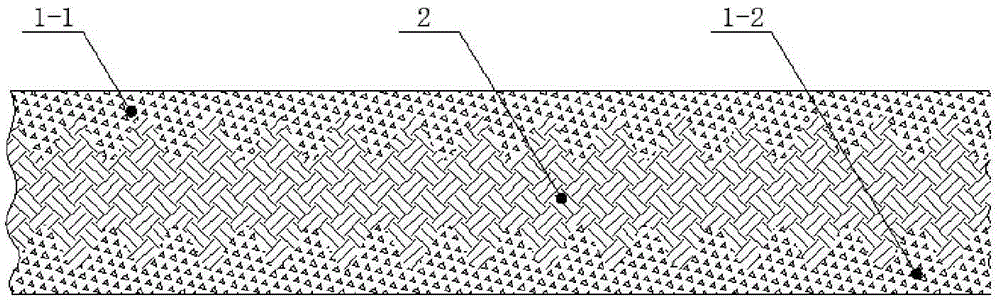

Image

Examples

Embodiment 1

[0047] The biomass resin of the present invention is expressed in parts by weight, and the raw materials are composed of: 100 parts of water, 0.26 parts of disodium hydrogen citrate, 1.48 parts of trisodium citrate, 0.1 part of seaweed gum, 0.2 part of guar gum, and 35 parts of defatted soybean powder. parts, 0.02 parts of Aspergillus niger protease preparation, 8 parts of potato starch, 5 parts of corn fiber powder, 0.03 parts of α-amylase, 0.01 part of cellulase, 0.2 parts of acetic anhydride, 0.5 parts of vinyltriethoxysilane, p-phenylene 0.05 part of diphenol, 0.02 part of nano silicon dioxide, 0.02 part of emulsified silicone oil, 0.1 part of isothiazolinone and 5 parts of magnesium oxide.

Embodiment 2

[0049] The preparation method of the biomass resin of embodiment 1 of the present invention, detailed steps are as follows:

[0050] (1) First, weigh various raw materials according to the ratio of the biomass resin described in Example 1;

[0051] (2) Add the weighed composite stabilizer into water to prepare an aqueous solution;

[0052] (3) Add the weighed vegetable protein powder to the solution obtained in step (2), and adjust the pH value to 7;

[0053] (4) Add the weighed protease preparation to the solution obtained in step (3), and react at 40°C for 200 minutes; when the viscosity of the system reaches 800-1200mPa.s, raise the temperature to 75°C and keep it warm for 18 minutes;

[0054] (5) Add the weighed plant starch and modified plant cellulose powder to the reaction solution obtained in step (4), cool down to 50°C, then add the weighed compound enzyme preparation, react for 70min; heat up to 75°C, and keep warm for 20min ;

[0055] (6) Cool down the reaction s...

Embodiment 3

[0058] The biomass resin of the present invention is expressed in parts by weight, and the raw materials are composed of: 100 parts of water, 0.4 part of ferrous sulfate, 0.1 part of sodium silicate, 0.5 part of polyvinyl alcohol, 0.01 part of sodium polyacrylate, 50 parts of defatted peanut powder, and 0.05 parts of protease preparation, 6 parts of corn starch, 3 parts of cotton fiber powder, 0.01 part of α-amylase, 0.01 part of β-amylase, 0.01 part of hemicellulase, 0.4 part of succinic anhydride, 0.2 part of diethylenetriamine, cyclo 0.2 parts of oxychloropropane, 3 parts of glycerin, 0.01 parts of dimethyl polyoxyalkylene, 0.05 parts of potassium sorbate, 0.05 parts of sodium propionate and 6 parts of clay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com