Method for using chemical vapor deposition method to prepare perovskite film solar cell

A vapor deposition method and a technology for solar cells, applied in the field of solar cells, can solve the problem of high cost and achieve the effects of less grain boundaries, large grains and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below through specific examples.

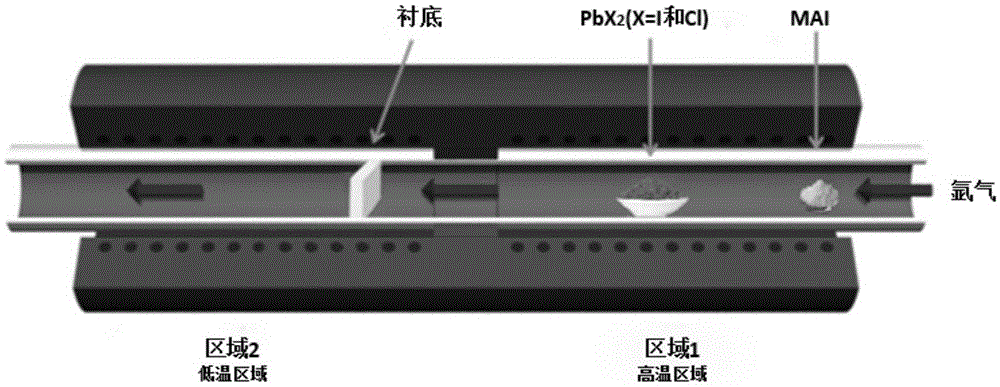

[0029] The present invention prepares perovskite thin-film solar cells through the following steps:

[0030] (1) Pretreating the substrate;

[0031] The substrate is FTO conductive glass. In this embodiment, the FTO conductive glass is produced by HARTFORD GLASS, USA, and has a sheet resistance of 8 ohms.

[0032] First, use an argon ion thinner to work for 10 minutes at 1KV (kilovolt) voltage and 75° incident angle to reduce the surface roughness of the FTO bottom; secondly, immerse the substrate in acetone in sequence, including Three percent polyethylene glycol monooctylphenyl ether (TritonX-100) in deionized water (Milipore, 18 MΩ-cm), and sonicated for 30 minutes in each of the above solutions; Rinse with deionized water and sonicate in isopropanol for 30 minutes; finally wash the substrate with deionized water, sonicate in deionized water for 30 minutes, and finally dry it with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com