Surface pretreatment method for reducing interface state density of SiC MOS

A technology of surface pretreatment and interface state density, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as instability, inability to fundamentally solve surface state problems, and easy surface oxidation, so as to avoid damage. , The effect of reducing SiCMOS interface state density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

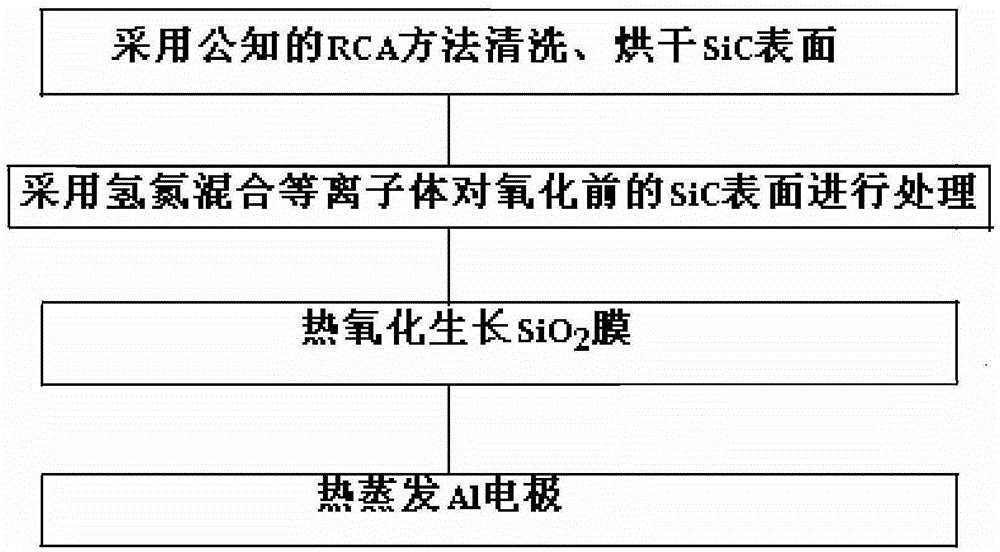

[0043] Such as figure 1 As shown, a surface pretreatment method for reducing the SiCMOS interface state density includes the following steps:

[0044] Step 1, using the known RCA method to clean and dry the SiC surface, specifically including the following sub-steps:

[0045] (a) Put SiC in a beaker, and use deionized water and ultrasonic cleaning several times until there is no obvious foreign matter;

[0046] (b) Wash with concentrated sulfuric acid, heat to 80°C, cook for 10 minutes, then soak for 30 minutes, add hydrogen peroxide and soak for 30 minutes, rinse the surface with deionized water several times;

[0047] (c) Using deionized water, H 2 o 2 , NH 4 OH mixed solution to clean, then wash with buffered hydrofluoric acid solution, and finally rinse the SiC surface several times with deionized water;

[0048] (d) using deionized water, H 2 o 2 , HCl mixed solution to clean, then wash with buffered hydrofluoric acid solution, and finally rinse the SiC surface sev...

Embodiment 2

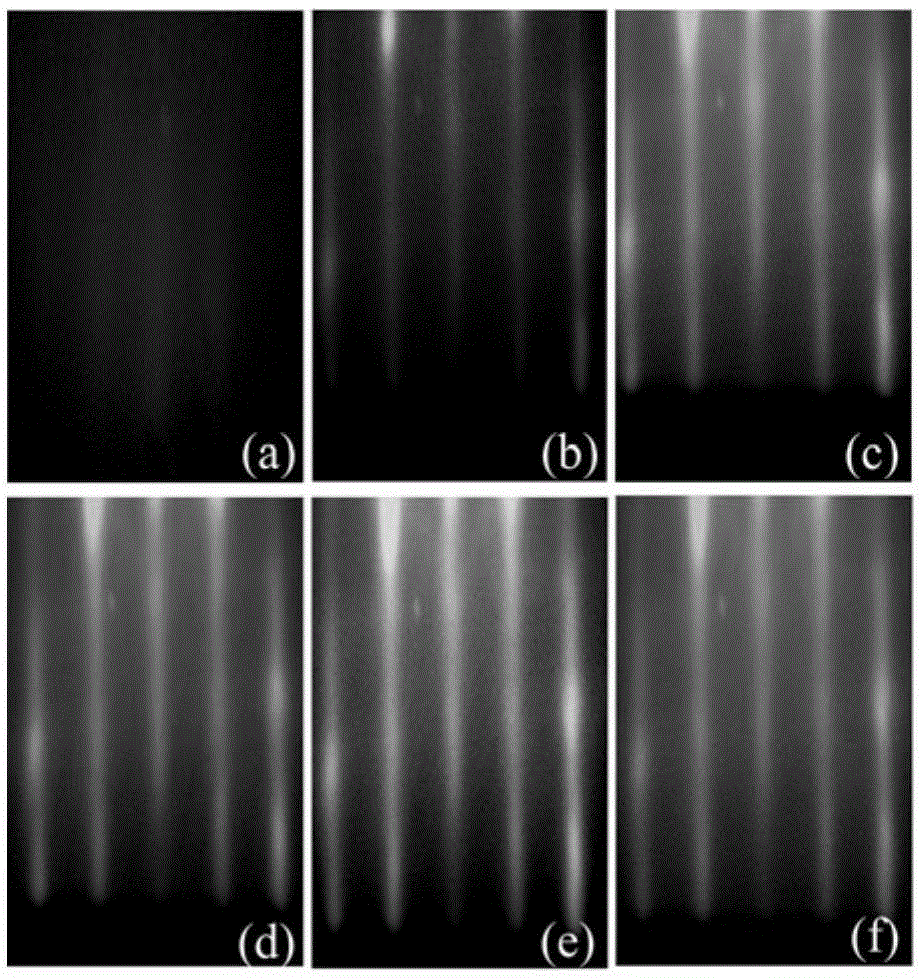

[0065] refer to figure 2 , although the RHEED image of the SiC surface cleaned by the traditional RCA method is in the form of linear stripes, the stripes are not clear and the contrast is poor, indicating that the atomic arrangement on the SiC surface is irregular and the single crystal orientation is poor. After hydrogen-nitrogen mixed plasma treatment, as the processing time increases, the RHEED image shows very clear linear stripes at 8 minutes, and the contrast is also very high, indicating that the SiC surface is clean, the atomic arrangement is regular, smooth, and the single crystal orientation is good. , and after calculation, the SiC surface treated by ECR hydrogen-nitrogen mixed plasma is approximately 1×1 structure, and no reconstruction occurs.

Embodiment 3

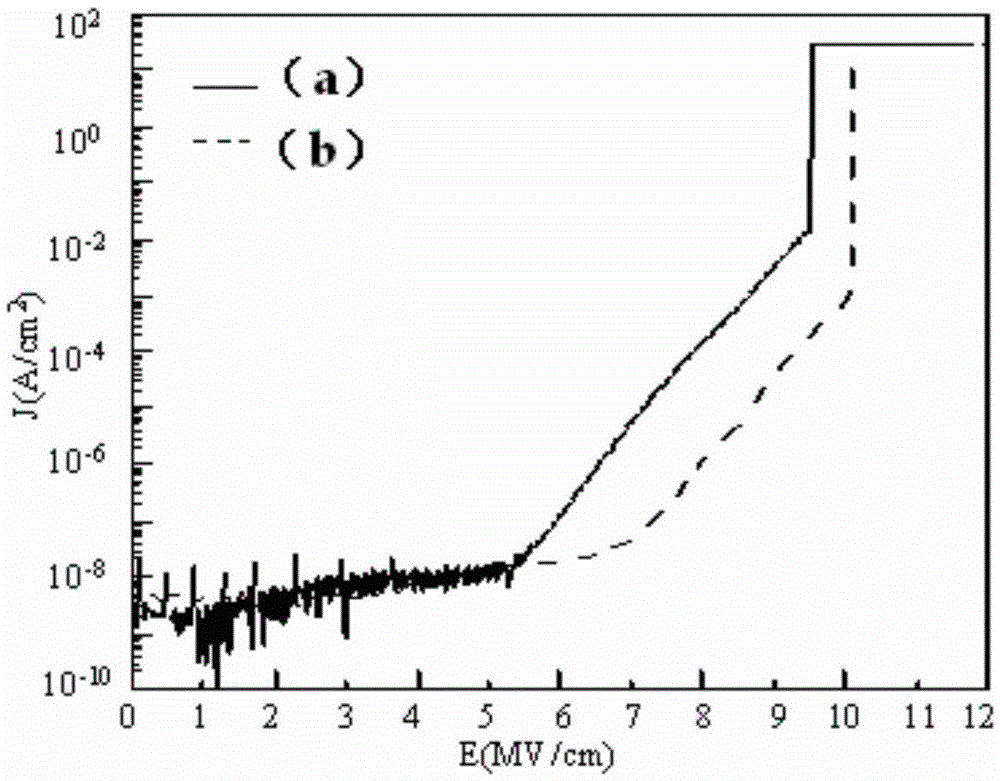

[0067] The SiCMOS capacitor device obtained by adopting the traditional method and the SiCMOS capacitor device obtained after the SiC surface is pretreated by the method of the present invention for 8 min are carried out, and the I-V characteristic test is carried out, and the Keithley4200 semiconductor parameter analyzer is used to complete the voltage scanning range. The length is 0.05V, and the hold time is 0.1s. The measured results are as image 3 As shown, compared with the SiCMOS capacitive device obtained by the traditional method and the method of the present invention, SiO 2 The breakdown field strengths of the films are 9.5MV / cm and 10.1MV / cm, and the barrier heights are 2.48eV and 2.74eV, respectively, indicating that the ECR hydrogen-nitrogen mixed plasma treatment improves SiO 2 insulating properties of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com