Organic amine system non-cyanide electroplating gold plating bath and method

An organic amine and gold electroplating technology, which is applied in the field of gold plating, can solve the problems of substandard coating performance and low stability of the plating solution, and achieve excellent welding performance, dense gold coating, and good bonding force

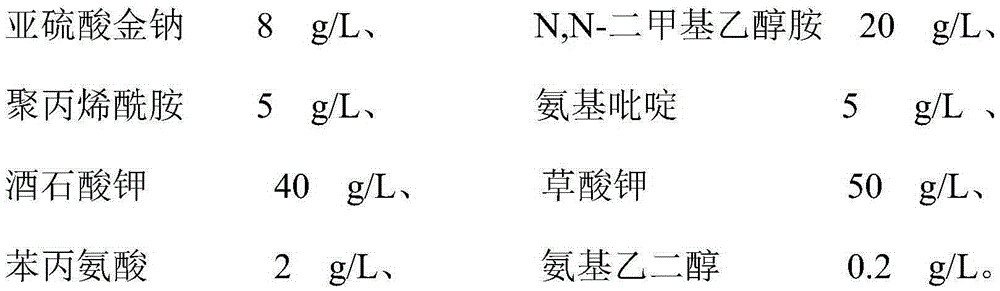

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

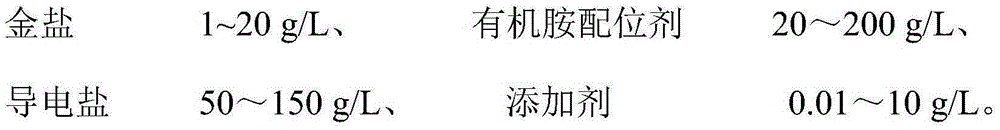

[0028] Plating solution composition:

[0029]

[0030] Plating process conditions: brass nickel-plated plate as cathode, room temperature, pH8, current density 3A dm -2 , plating for 10min.

[0031] Effect: The coating is smooth and bright without obvious defects.

Embodiment 2

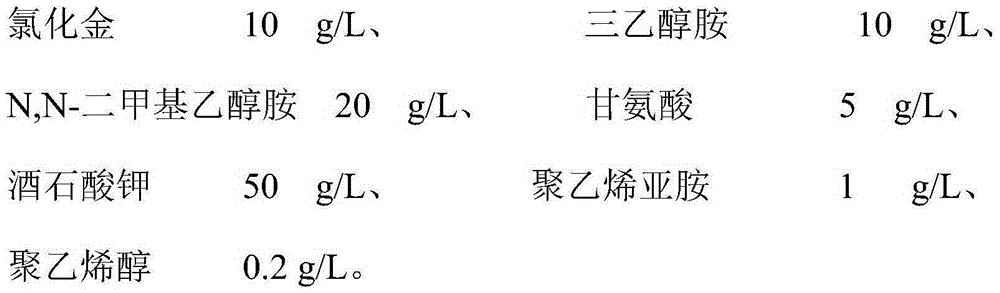

[0033] Plating solution composition:

[0034]

[0035] Plating process conditions: the circuit board nickel plating sample is used as the cathode, the temperature is controlled at 40 ° C, pH 6, the solution is convectively stirred, and the current density is 2A dm -2 , plating for 5 minutes.

[0036] Effect: The gold on the surface of the line is uniform without overflow, and the combination is firm.

Embodiment 3

[0038] Plating solution composition:

[0039]

[0040] Plating process conditions: iron-based metal decorative pendant as cathode, double anode control, temperature control 40 ℃, pH9, solution convection stirring, current density 4A dm -2 , plating for 5 minutes.

[0041] Effect: The gold on the surface of the pendant is uniform, bright without color difference, and without missing plating.

[0042] The formulation and process of the plating solution of the present invention are suitable for gold-plating treatment on the surface of copper, nickel, cobalt, palladium, silver, gold and other metals and their alloys. For non-metallic materials, a metal layer needs to be pre-plated and then gold-plated. The method of electroplating gold is as follows: after each component is dissolved and mixed, the pH of the plating solution is adjusted to 5-9, and the plating solution is heated at room temperature or below 50°C. The plated piece to be processed is the cathode, and the anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com