Active macromonomer, and preparation method and application thereof

A technology of active macromonomers and active intermediates, applied in the field of their preparation and active macromonomers, can solve problems such as poor dispersion performance, achieve high water reduction rate, increase steric hindrance effect, and promote cement water reconciliation reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

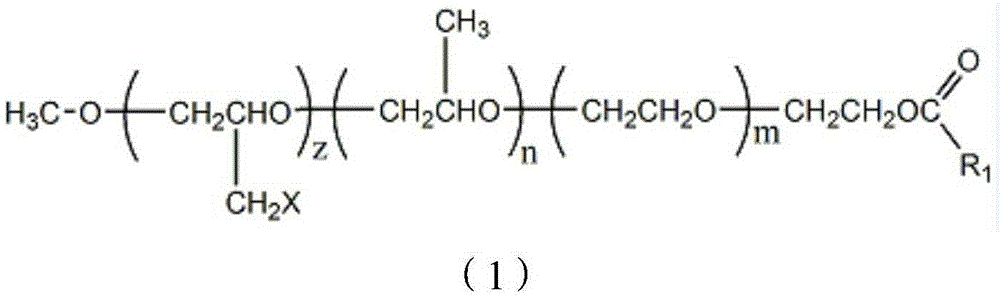

[0051] The preparation method of active macromonomer of the present invention is synthesized through the following steps:

[0052] 1) Synthesis of methoxyl hydroxyl PEG intermediate

[0053] Into the closed autoclave, inject methanol, ethylene oxide or a mixture of ethylene oxide and propylene oxide, epihalohydrin, catalyst, stir, and react at 80-150 ° C for 2-10 hours to obtain the reaction product A Oxyhydroxy PEG intermediate;

[0054] Among them, the molar ratio of methanol, ethylene oxide or a mixture of ethylene oxide and propylene oxide, and epihalohydrin is methanol: ethylene oxide or a mixture of ethylene oxide and propylene oxide: epihalohydrin =1:5~200:1~150; the epihalohydrin is one of epichlorohydrin, epibromohydrin or epoxyiodohydrin; the catalyst is sodium hydride or sodium;

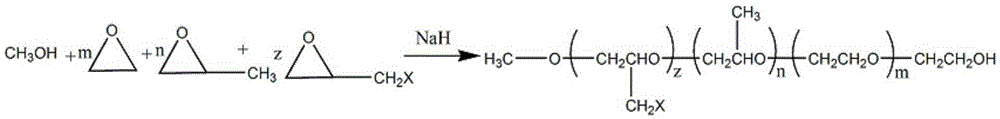

[0055] Reaction equation in this step is (when catalyst is sodium hydride):

[0056]

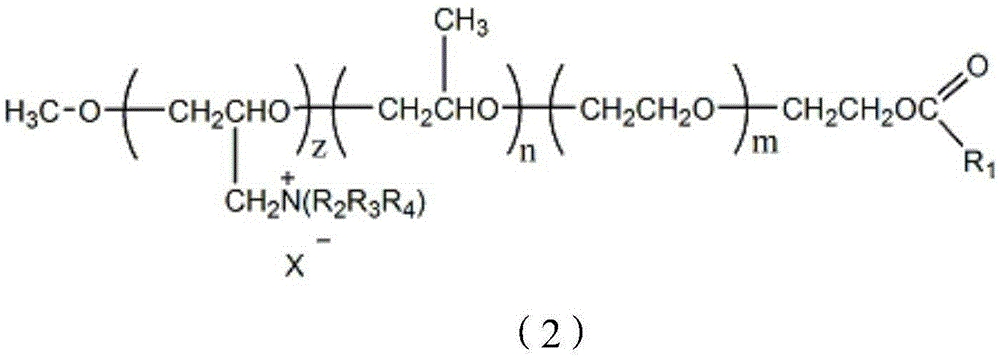

[0057] 2) Synthesis of methoxy PEG active intermediate

[0058] Add the methoxyhydroxy PEG int...

Embodiment 1

[0070] An embodiment of the methoxy PEG active intermediate of the present invention, the synthesis of the methoxy PEG active intermediate comprises the following steps:

[0071] 1) Synthesis of methoxy hydroxyl intermediate

[0072] Into a closed autoclave, respectively inject 1.0mol methanol, 100mol ethylene oxide, 50mol epichlorohydrin and 1g sodium hydride, stir, and react at 80°C for 2 hours to obtain the reaction product methoxy PEG hydroxyl intermediate;

[0073] 2) Synthesis of methoxy PEG active intermediate

[0074] In a 500ml four-necked glass flask with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 0.5mol of the methoxyl hydroxyl intermediate, 0.6mol of acrylic acid, 1g of methanesulfonic acid and 0.01g of Hydroquinone, stirred, and reacted at 80°C for 3 hours to obtain the active intermediate of the reaction product methoxy PEG.

Embodiment 2

[0076] An embodiment of the methoxy PEG active intermediate of the present invention, the synthesis of the methoxy PEG active intermediate comprises the following steps:

[0077] 1) Synthesis of methoxyl hydroxyl PEG intermediate

[0078] Into a closed autoclave, respectively inject 0.5mol methanol, 50mol ethylene oxide, 20mol epichlorohydrin and 2.5g sodium, stir, and react at 100°C for 25h to obtain the reaction product methoxyl hydroxyl intermediate;

[0079] 2) Synthesis of methoxy PEG active intermediate

[0080] In a 500ml four-neck glass flask with a stirrer, a thermometer, a reflux condenser, and a dropping device, add 0.5mol of the methoxyl hydroxyl intermediate, 0.55mol of methacrylic acid, and 1.5g of methanesulfonic acid synthesized in step 1). and 0.01g of p-methyl ether phenol, stirred, and reacted at 120°C for 15 hours to obtain the active intermediate of the reaction product methoxy PEG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com