Method for preparing porous nanometer silicon through air auxiliary

An air-assisted, nano-silicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as high energy consumption, high reaction temperature, and large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Process the rice husk to obtain 0.6g of silicon dioxide particles and 1g of magnesium powder and mix them uniformly and put them into a sealed stainless steel high-temperature kettle;

[0028] (2) Put the mixture in (1) into a tube furnace filled with inert gas (Ar) and heat it to 650°C at a heating rate of 5°C / min for 6 hours to obtain the product, and take it out after cooling to room temperature with the furnace;

[0029] (3) Put the product obtained in (2) into a corundum crucible, and then directly put it into a muffle furnace and heat it to 600°C for 10 hours at a heating rate of 10°C / min in the air. After the product is cooled to room temperature with the furnace, take it out ;

[0030] (4) Pickling the product obtained in (3) with 1 mol / L hydrochloric acid to remove magnesium oxide, washing, filtering, and drying to obtain porous nano-silicon.

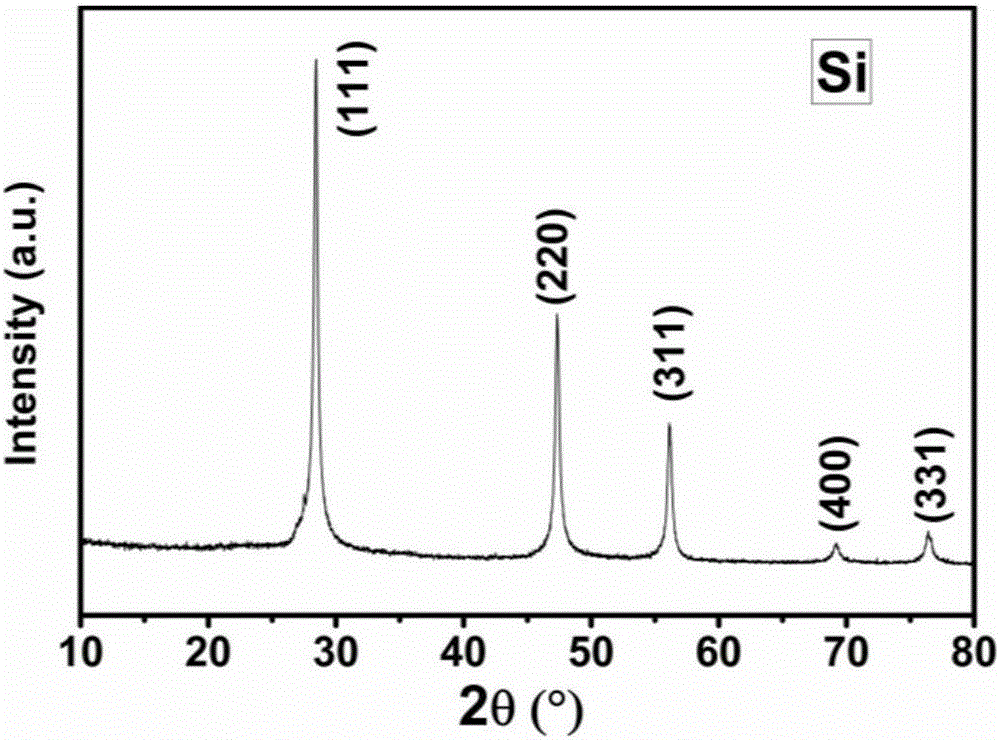

[0031] Depend on figure 1 The XRD diffraction pattern of XRD shows that at 28.4 °, 47.3 ° and 56.1 °, the three ...

Embodiment 2

[0033] (1) Process the rice husk to obtain 0.6g of silicon dioxide particles and 0.6g of magnesium powder and mix them uniformly and put them into a sealed stainless steel high-temperature kettle;

[0034] (2) Put the mixture in (1) into a tube furnace filled with inert gas (Ar) and heat it to 400°C at a heating rate of 10°C / min and keep it for 1 hour to obtain the product. After the product is cooled to room temperature with the furnace, take it out;

[0035] (3) Put the product obtained in (2) into a corundum crucible, and then directly put it into a tube furnace with pure oxygen and heat it to 300°C at a heating rate of 10°C / min for 12h, and wait for the product to cool down to room temperature with the furnace after taking out;

[0036] (4) Pickling the product obtained in (3) with 1 mol / L hydrochloric acid to remove magnesium oxide, washing, filtering, and drying to obtain porous nano-silicon.

Embodiment 3

[0038] (1) Mix 1.2g of silicon dioxide particles obtained by straw treatment with 2g of magnesium powder and put them into a sealed stainless steel high-temperature kettle;

[0039] (2) Put the mixture in (1) into a tube furnace filled with inert gas (Ar) and heat it to 500°C for 3 hours at a heating rate of 1°C / min to obtain the product, and take it out after cooling to room temperature with the furnace;

[0040] (3) Put the product obtained in (2) into a corundum crucible, then directly put it into a muffle furnace and heat it to 500°C for 6 hours at a heating rate of 5°C / min in the air. After the product is cooled to room temperature with the furnace, take it out ;

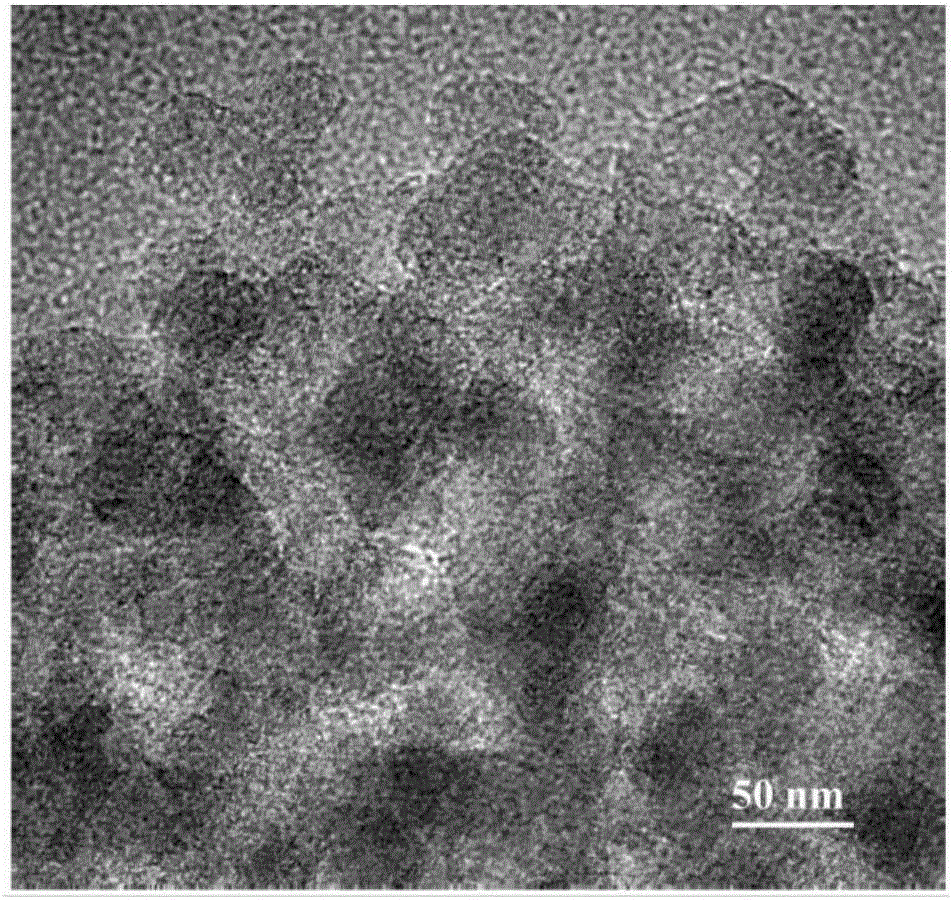

[0041] (4) Pickling the product obtained in (3) with 1 mol / L hydrochloric acid to remove magnesium oxide, washing, filtering, and drying to obtain three-dimensional porous nano-silicon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com