Surface coating method of 5V lithium ion battery positive pole material LiNi0.5-xMn1.5MxO4

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrode manufacturing, electrode heat treatment, etc., can solve the problems of electrode charge and discharge capacity and cycle reversible capacity decay, low initial discharge capacity, poor cycle performance, etc. And cycle performance, high reversible specific capacity, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 5g active material LiNi 0.48 mn 1.5 Fe 0.02 o 4 Grind and mix with 0.5g acetylene black, disperse in 25ml of absolute ethanol, and ultrasonically pulverize for 20min; mix the above mixture together with ethanol by ball milling for 3h, dry at 80°C for 3h, grind and pulverize; calcine in a nitrogen atmosphere at a constant temperature of 300°C for 1h , and then the furnace is lowered to room temperature, and the carbon-coated high-voltage positive electrode material is obtained by grinding.

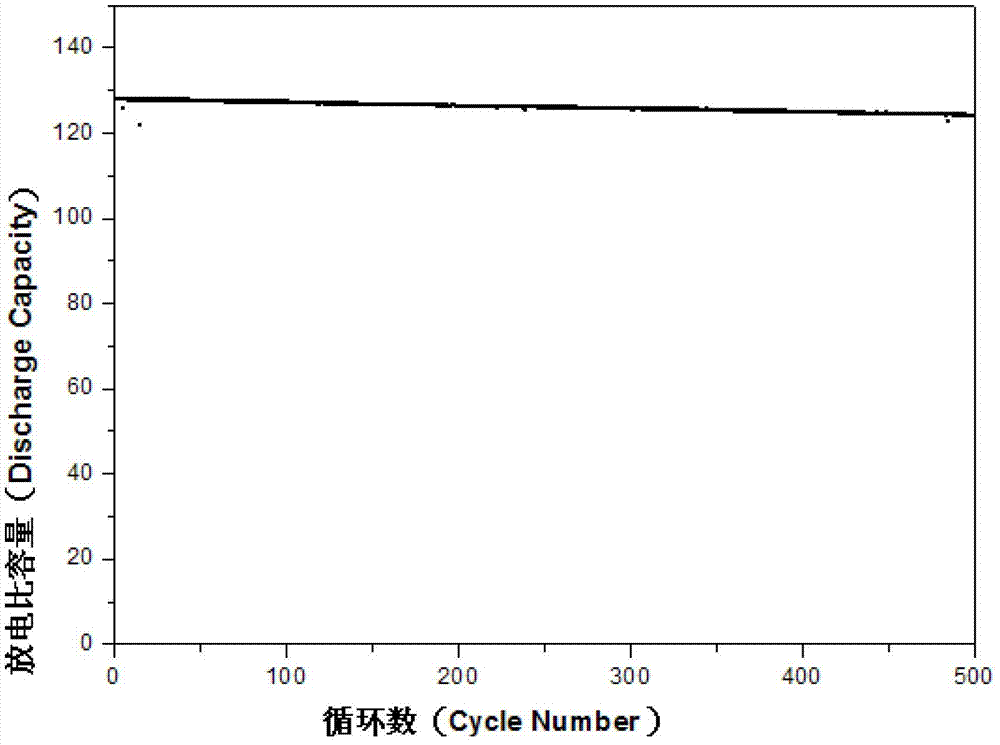

[0038] Electrolyte of EC:EMC:DMC (1:1:1, V / V) was used to assemble a 2016 button battery with metal lithium as the negative electrode. The capacity retention rate of 500 times of 2C cycles was tested on the Land charge and discharge tester. 95%.

Embodiment 2

[0040] 5g active material LiNi 0.45 mn 1.5 Ti 0.05 o 4 Grind and mix with 2g of sucrose, disperse in 25ml of absolute ethanol, and ultrasonically pulverize for 20min; mix the above mixture together with ethanol by ball milling for 2h, dry at 80°C for 3h, grind and pulverize; calcinate at constant temperature at 300°C for 3h in a nitrogen atmosphere, and then With the furnace down to room temperature, the carbon-coated high-voltage positive electrode material can be obtained by grinding.

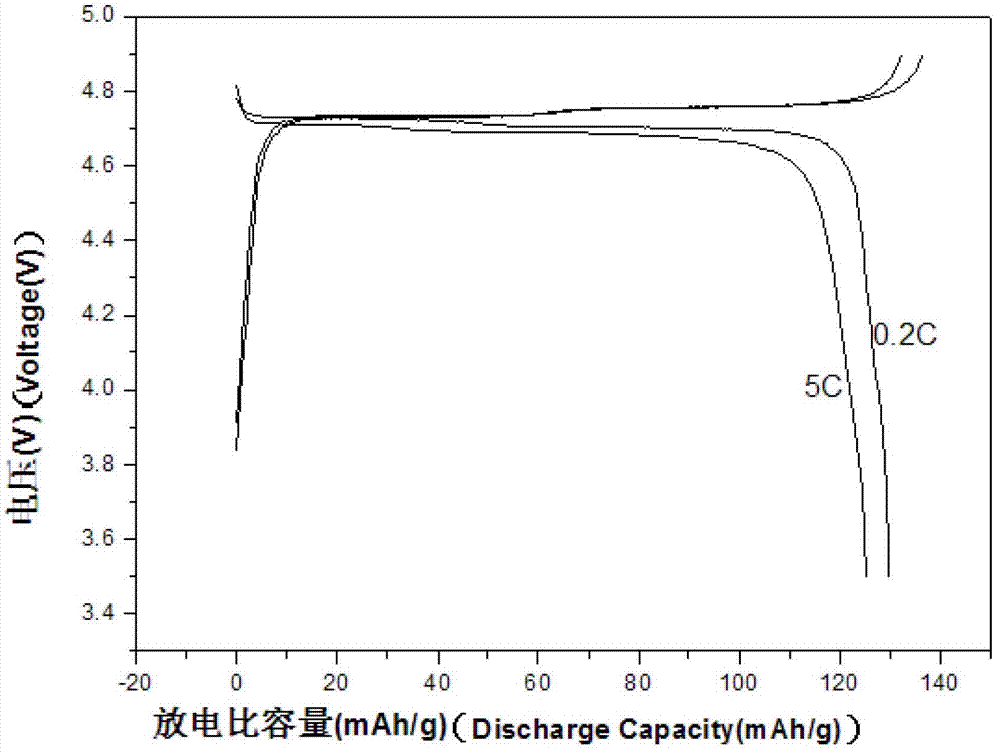

[0041] Electrolyte of EC:EMC:DMC (1:1:1, V / V) was used to assemble a 2016 button battery with metal lithium as the negative electrode. The discharge capacity at 5C rate was 127mAh when tested on the Land charge and discharge tester. / g, which is 98% of 0.2C.

Embodiment 3

[0043] 5g active material LiNi 0.45 mn 1.5 Mg 0.05 o 4 Grind and mix with 0.5g acetylene black, disperse in 25ml of absolute ethanol, and ultrasonically pulverize for 20min; mix the above mixture together with ethanol by ball milling for 3h, dry at 80°C for 3h, grind and pulverize; calcine in a nitrogen atmosphere at a constant temperature of 300°C for 1h , and then the furnace is lowered to room temperature, and the carbon-coated high-voltage positive electrode material is obtained by grinding.

[0044] Electrolyte of EC:EMC:DMC (1:1:1, V / V) was used to assemble a 2016 button battery with metal lithium as the negative electrode. The discharge capacity at 5C rate was 128mAh when tested on the Land charge and discharge tester. / g, the capacity retention rate of 500 cycles at 2C is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com