Method for preparing iron-silicon-aluminum soft magnetic powder core through warm-pressing

A technology of sendust and magnetic powder core, which is applied in the field of powder metallurgy manufacturing of metal materials, to achieve significant economic effects, low loss, and reduced pressing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

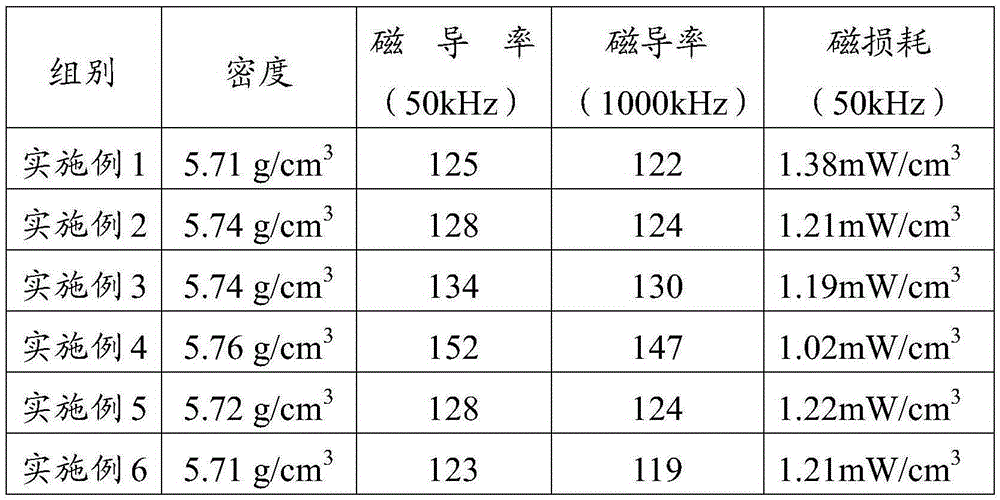

Examples

Embodiment 1

[0031] An embodiment of the method for preparing sendust soft magnetic powder core by warm pressing in the present invention, the preparation method of the soft magnetic powder core described in this embodiment comprises the following steps:

[0032] (1) Passivate the initial soft magnetic alloy powder with a phosphoric acid solution with a mass percent concentration of 0.4%, and dry it; the mass ratio of the phosphoric acid solution to the initial soft magnetic alloy powder is 0.5:1;

[0033] (2) The soft magnetic alloy powder after step (1) is dried is mixed evenly with binding agent, and the mass ratio of described binding agent and initial soft magnetic alloy powder is 2%, and described binding agent is sodium silicate, A mixture of high temperature resistant silicone resin, and the mass ratio of the sodium silicate and high temperature resistant silicone resin is 2:1;

[0034] (3) Dry and sieve the mixed powder obtained in step (2), then add nano silicon dioxide to mix an...

Embodiment 2

[0038] An embodiment of the method for preparing sendust soft magnetic powder core by warm pressing in the present invention, the preparation method of the soft magnetic powder core described in this embodiment comprises the following steps:

[0039] (1) Passivate the initial soft magnetic alloy powder with a phosphoric acid solution with a mass percent concentration of 1%, and dry it; the mass ratio of the phosphoric acid solution to the initial soft magnetic alloy powder is 0.6:1;

[0040] (2) The soft magnetic alloy powder after step (1) is dried is mixed evenly with binding agent, and the mass ratio of described binding agent and initial soft magnetic alloy powder is 1.8%, and described binding agent is sodium silicate, A mixture of high temperature resistant silicone resin, and the mass ratio of the sodium silicate and high temperature resistant silicone resin is 3:2;

[0041] (3) Dry and sieve the mixed powder obtained in step (2), then add nano silicon dioxide to mix an...

Embodiment 3

[0045] An embodiment of the method for preparing sendust soft magnetic powder core by warm pressing in the present invention, the preparation method of the soft magnetic powder core described in this embodiment comprises the following steps:

[0046] (1) Passivate the initial soft magnetic alloy powder with a phosphoric acid solution with a mass percent concentration of 2%, and dry it; the mass ratio of the phosphoric acid solution to the initial soft magnetic alloy powder is 0.8:1;

[0047] (2) The soft magnetic alloy powder after step (1) is dried is mixed evenly with binder, and the mass ratio of described binder and initial soft magnetic alloy powder is 1.6%, and described binder is sodium silicate, A mixture of high temperature resistant silicone resin, and the mass ratio of the sodium silicate and high temperature resistant silicone resin is 3:2;

[0048] (3) Dry and sieve the mixed powder obtained in step (2), then add nano silicon dioxide to mix and coat, the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com