Flexible micro-nanofiber stranded wire with electromagnetic performance and preparation method thereof

A technology of micro-nano fibers and magnetic nanoparticles, which is applied in the fields of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, and can solve the problems of troublesome preparation of precursors, lack of electrical conductivity, and limited application scope of materials. , to achieve the effect of no obvious oxygen inhibition phenomenon, safe and environmentally friendly preparation process, and excellent tensile recovery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

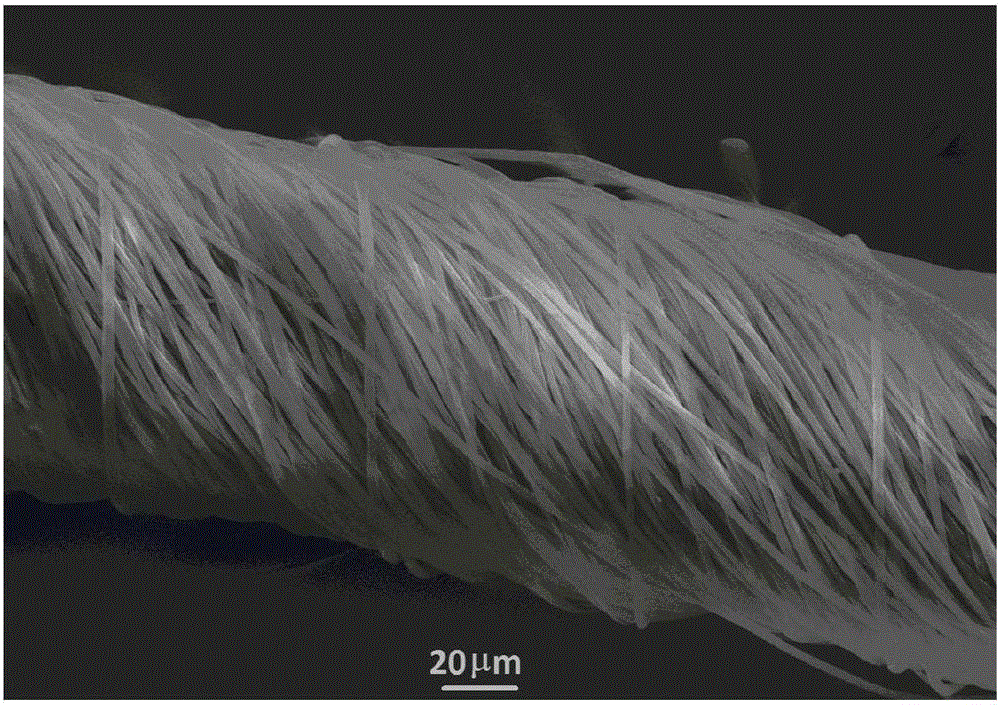

Image

Examples

Embodiment 1

[0035] A flexible micro-nano fiber stranded wire with electromagnetic properties, comprising the following steps:

[0036] (1) Configure the spinning precursor solution: add 8 grams of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)) and 0.4 grams of liquid photoinitiator (photoinitiator1173, 2-hydroxy- 2-methyl-1-phenyl-1-acetone, Aldrich), and 2 grams of polyaniline powder (PANI, average molecular weight Mw>15,000, Aladdin), 0.3 gram of ferric oxide powder was carried out shading stirring with a stirrer, using Heating in a water bath at 40 degrees, stirring for 3 hours, mixing the photoinitiator, urethane acrylate, polyaniline and ferric oxide evenly, and standing at room temperature for 1 day, so that the urethane acrylate is pre-polymerized to a certain extent, and the prepared Spinning precursor;

[0037] (2) Preparation of stranded wire: pour the spinning precursor solution prepared in step (1) into an aluminum spinneret with an inner diam...

Embodiment 2

[0040] A flexible micro-nano fiber stranded wire with electromagnetic properties, comprising the following steps:

[0041] (1) Configure the spinning precursor solution: add 8 grams of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)) and 0.4 grams of liquid photoinitiator (photoinitiator1173, 2-hydroxy- 2-Methyl-1-phenyl-1-propanone, Aldrich), 2g ferric oxide powder (Aladdin), and 1 gram of PEDOT solution (Aladdin), use a stirrer for shading stirring, use a 50-degree water bath to heat, stir For 1 hour, the photoinitiator, urethane acrylate and polyaniline were mixed evenly, and left to stand at room temperature for 2 days, so that the urethane acrylate was prepolymerized to a certain extent to make a spinning precursor solution;

[0042] (2) Preparation of stranded wire: Pour the prepared spinning precursor liquid into an aluminum spinneret with an inner diameter of 1.2 cm, the tip of the spinneret is 3 mm in size, and feed nitrogen into the air...

Embodiment 3

[0045] A flexible micro-nano fiber stranded wire with electromagnetic properties, comprising the following steps:

[0046] (1) Configure the spinning precursor solution: add 8 grams of polyester acrylate (CN750, Sartomer (Guangzhou) Chemical Co., Ltd.), 0.4 grams of liquid photoinitiator (photoinitiator1173, 2-hydroxy- 2-methyl-1-phenyl-1-propanone, Aldrich), 0.5g cobalt powder and 0.1 gram graphene solution (Aladdin), carry out light-shielding stirring with agitator, adopt 45 degree water bath to heat, stir 1.5 hours, make light The initiator, urethane acrylate and graphene are mixed evenly, and left to stand for 1.5 days at room temperature under natural light, so that the polyester acrylate is pre-polymerized to a certain extent to obtain a precursor solution;

[0047] (2) Preparation of stranded wire: pour the spinning precursor solution prepared in step (1) into an aluminum spinneret with an inner diameter of 1.2 cm, the tip of the spinneret is 2.5 mm in size, and nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com