A preparation method of high-density ferrite-carbon nanotube composite bulk material

A carbon nanotube composite and bulk material technology, which is applied in the field of preparation of high-density ferrite-carbon nanotube composite bulk materials, can solve problems such as low consistency, easy deformation and cracking, and long production cycle, and achieve The effects of improving production efficiency, promoting grain growth, and increasing sintering density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the chemical expression of the ferrite-carbon nanotube composite material is 1%CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 , where 1% means that CNTs account for Ni 0.5 Zn 0.5 Fe 2 o 4 mass percent content. The 1%CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 The specific preparation method of the bulk material is as follows:

[0041] (1) Weigh 0.5g carbon nanotubes and 150ml concentrated nitric acid to mix, reflux 5h in the oil bath of 150 ℃, prepare the modified carbon nanotubes, then dissolve the modified carbon nanotubes in the process of sodium lignosulfonate In a saturated solution, ultrasonically crush for 45 minutes to obtain a uniformly dispersed carbon nanotube solution;

[0042] (2) Press Ni at room temperature 2+ : Zn 2+ : Fe 3+ The molar ratio is 0.5:0.5:2 and Ni(NO 3 ) 2 ·6H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, add distilled water and the carbon nanotube solution configured in (1) to obtain a mixed solution, wherein CNTs: Ni 0.5 Zn 0...

Embodiment 2~8

[0047] Same as Example 1, Examples 2-8 are CNTs-MeFe 2 o 4 The preparation method of block material, this method is basically identical with embodiment 1, difference is chemical expression MeFe 2 o 4 The Me element, sintering temperature, and holding time are different, as shown in Table 1 below.

[0048] Table 1 CNTs-MeFe in Examples 2-8 2 o 4 The chemical expression and process conditions

[0049] Example

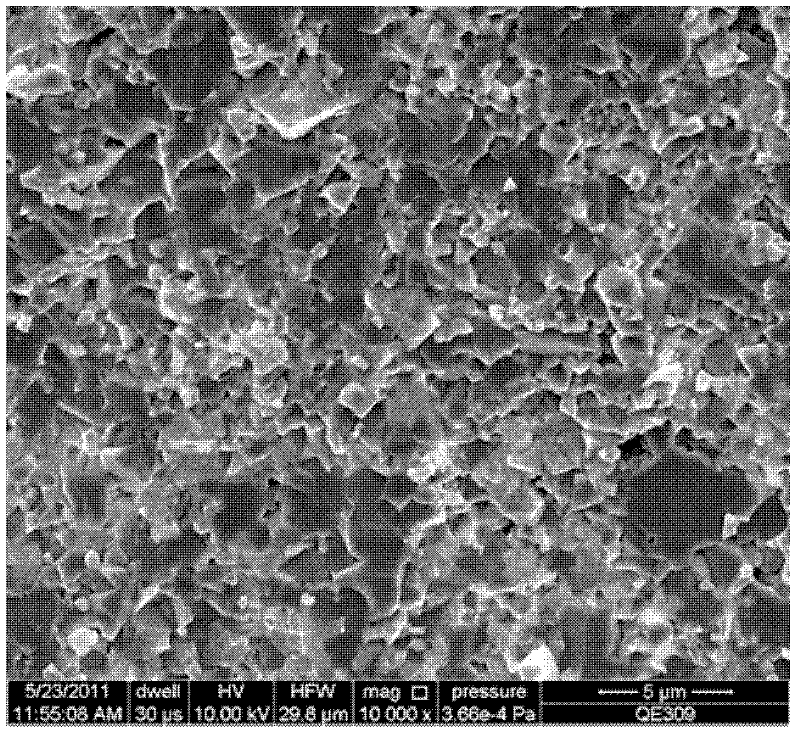

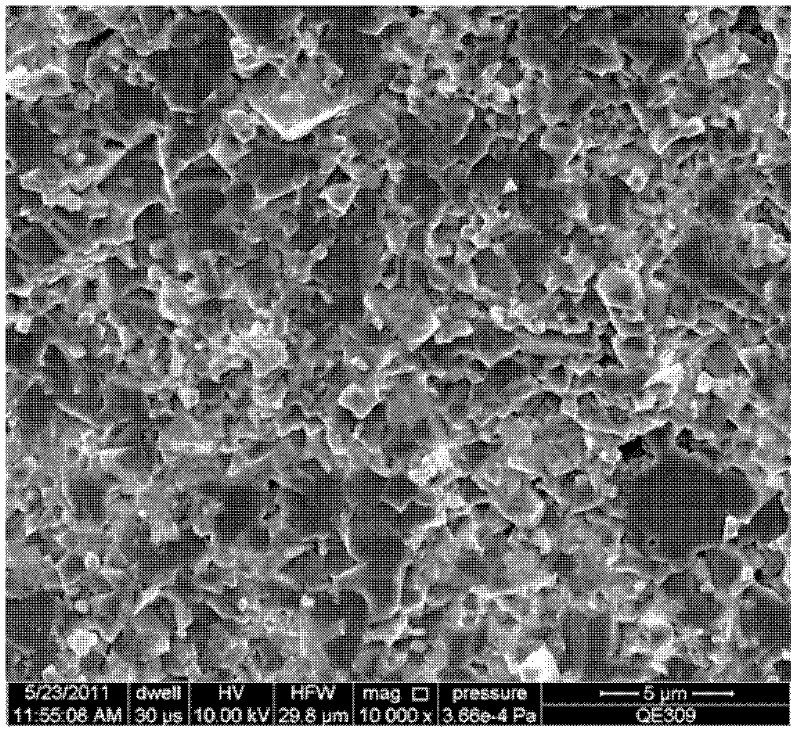

[0050] For the CNTs-MeFe prepared above 2 o 4 The sample of the bulk material is measured and analyzed, and the relative density of the sample is 98%-99.9% measured by the Archimedes drainage method; the fracture morphology of the sample is observed with a scanning electron microscope, and the obtained morphology is similar to figure 1 , indicating that the sample has a high degree of sintering and densification; the room temperature hysteresis loop of the sample is measured with a physical property measurement system, and a similar figure 2 The curve s...

Embodiment 9~17

[0052] Basically the same as Example 1, Examples 9-17 are CNTs-AFe 12 o 19 The preparation method of the bulk material, the difference is the chemical formula AFe 12 o 19 And the combination of A, as well as the sintering temperature and holding time are different, as shown in Table 2 below.

[0053] Table 2 Synthesis of CNTs-AFe in Examples 9-17 12 o 19 The chemical expression and process conditions

[0054] Example

[0055] For the CNTs-AFe prepared above 12 o 19 The sample of the bulk material is measured and analyzed, and the relative density of the sample is 98%-99.9% measured by the Archimedes drainage method; the fracture morphology of the sample is observed with a scanning electron microscope, and the obtained morphology is similar to figure 1 , indicating that the sample has a high degree of sintering and densification; the room temperature hysteresis loop of the sample is measured by a physical property measurement system, which shows that the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com