Ti2AlNb base alloy

A technology of base alloy and alloy composition, applied in the field of Ti-Al intermetallic compounds, can solve the problems of low toughness, inability to manufacture large ingots, etc., and achieve the effect of good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

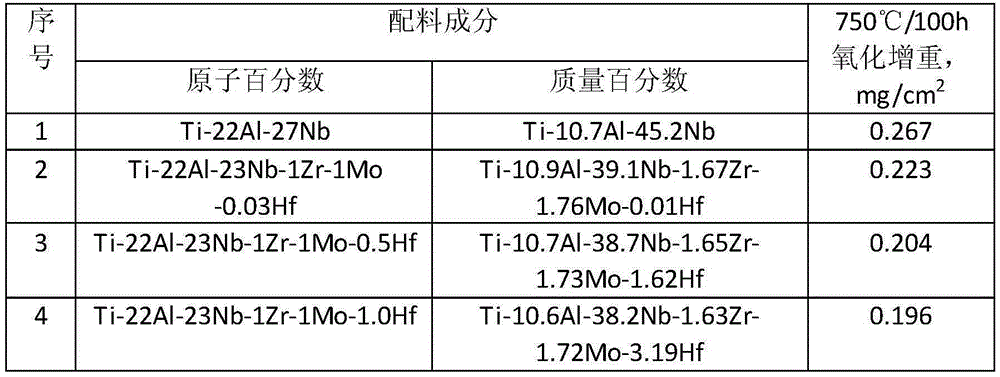

Embodiment 1~4

[0016] The ingredients of Examples 1-4 are shown in Table 1. Button ingots with 4 ingredients were prepared using a non-consumable vacuum melting furnace, and the weight of the ingredients was 50 g. The test process is as follows: According to the mass percentages of the ingredients shown in Table 1, calculate and weigh the raw materials required for 50g ingot casting, taking component 2 as an example, weigh 22.29g of titanium sponge, 5.31g of pure aluminum foil, and 19.12g of pure Nb Cut, 0.85g molybdenum powder, 0.81g sponge zirconium, 1.59g pure hafnium bar, wrap the molybdenum powder into particles with aluminum foil, put all the raw materials into the crucible of the non-consumable vacuum furnace, smelt after vacuuming, complete the smelting and After cooling, turn the button ingot over and put it into the crucible again, and melt it again, repeating the melting for a total of 5 times to ensure the uniform composition. Follow the same method to complete the smelting of th...

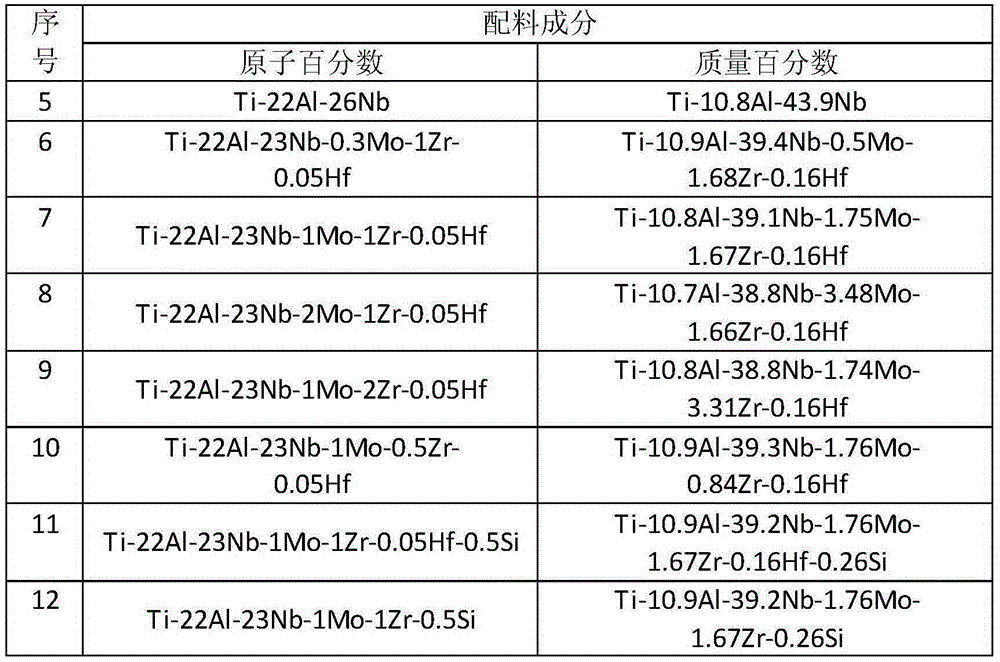

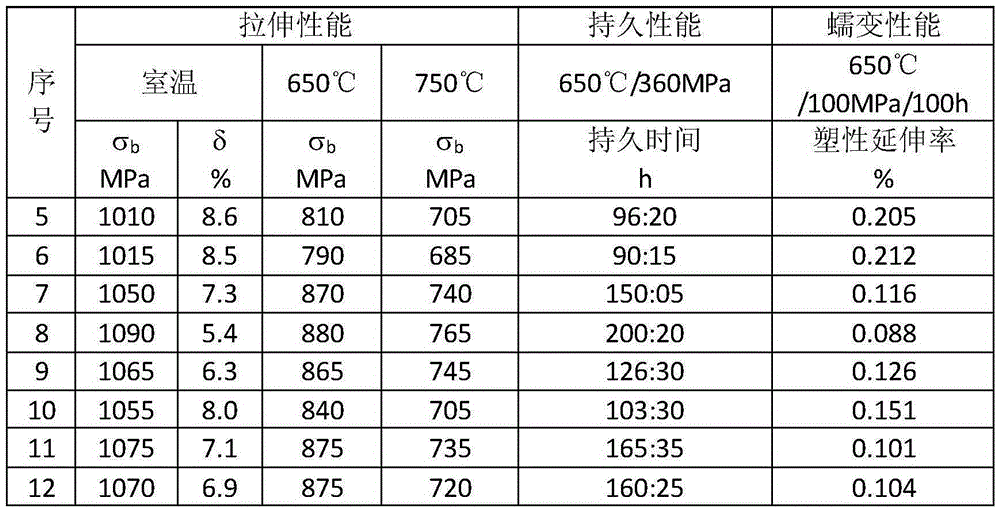

Embodiment 5~12

[0020] The batching composition of Examples 5-12 is shown in Table 2, and the ingot was prepared according to the batching composition shown in Table 2, and the batching weight was 112kg. Ingots were prepared by three vacuum consumable melting processes. The process is: ingredient calculation, raw material weighing, piezoelectric electrode (electrode specification is A single electrode block weighs 7kg), welding electrodes and vacuum consumable melting. The raw materials required to prepare ingots include: titanium sponge, pure aluminum beans, Al-75Nb alloy, Al-60Mo alloy, zirconium sponge, pure hafnium flakes and Al-10Si alloy. First, calculate the single electrode according to the mass percentage of the ingredients The amount of various raw materials required, after mixing, is pressed in the special mold of the hydraulic press to form 16 electrode blocks are pressed for each component; 4 electrode blocks are welded into a long electrode, and one smelting is carried out, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com