Marine organism polysaccharide derivative double-layer film slow-release fertilizer and preparation method thereof

A technology of marine biological polysaccharides and slow-release fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of reducing the pores and solubility of membrane materials, failing to achieve slow-release effects, and high initial release rates, and achieve good slow-release Effects, Improving Plant Immunity, Ease of Degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

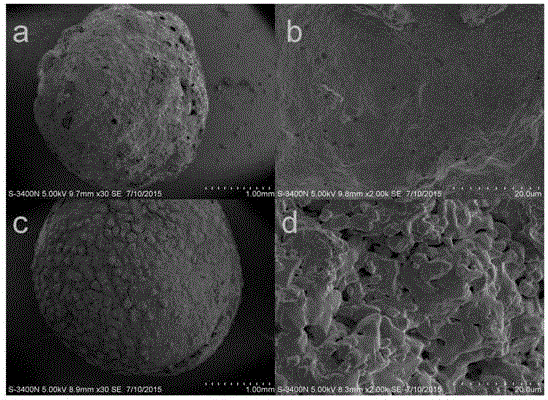

Image

Examples

Embodiment 1

[0024] Embodiment 1 (microcrystalline wax chitosan glutaraldehyde crosslinked double-layer membrane slow-release fertilizer)

[0025] Dissolve 6 g of chitosan in 400 mL of 2% acetic acid solution to obtain a chitosan solution with a mass fraction of 1.5%, add 300 μL of glutaraldehyde with a mass fraction of 50%, and stir at room temperature until the solution is yellow and viscous. Weigh 100g of fertilizer (commercially available common fertilizer) and dip it in, take it out and lay it flat, place it in an oven to dry at 60°C, and screen the fertilizer with uniform coating. Heat the microcrystalline wax in a water bath at 95°C until it is completely dissolved, immerse it in the above-mentioned coated fertilizer, take it out and quickly add it to deionized water (at room temperature), the dissolved microcrystalline wax solidifies quickly on the surface of the fertilizer when it is cold, and then lay it flat to dry .

Embodiment 2

[0026] Embodiment 2 (microcrystalline wax calcium alginate double-layer film slow-release fertilizer)

[0027] Dissolve 10 g of sodium alginate in 500 mL of deionized water to obtain a 2% sodium alginate solution. Weigh 100g of fertilizer (commercially available common fertilizer) and immerse it into a calcium chloride solution with a mass fraction of 5%, take it out and lay it flat, place it in an oven for drying at 60°C, and screen the evenly coated fertilizer. The microcrystalline wax is heated in a water bath at 95°C until it is completely dissolved, immersed in the above-mentioned fertilizer, and quickly added to deionized water (at room temperature) after being taken out. The dissolved microcrystalline wax solidifies quickly on the surface of the fertilizer when it is cold, and it can be flattened to dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com