Sulfur oxide gadolinium (Gd2O2S) scintillation ceramics preparation method

A technology of scintillation ceramics, gadolinium oxysulfide, applied in chemical instruments and methods, radiation intensity measurement, luminescent materials, etc., can solve the problems of high sintering temperature, low production efficiency, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In order to overcome one or more defects of the prior art, the invention provides a preparation method of GOS scintillation ceramics, which comprises the following steps:

[0021] 1) To Gd with a median particle size of 5-9 μm 2 o 2 S: Pr, Ce, sintering aids are added to the scintillation powder, preferably, the powder is commercially available, wherein the doping amount of Pr ions is 500-800ppm by mass content, and the doping amount of Ce ions is mass content Content 10-100ppm. In addition, preferably wherein the sintering aid is LiF and / or Li 2 GeF 6 ; The addition of the sintering aid is about 0.02-1%, preferably 0.1-1%. The mixed powder is ball milled to make it uniformly mixed, and optionally refined to obtain a powder containing a sintering aid. Preferably, the ball milling is carried out on a planetary ball mill, more preferably with absolute ethanol and zirconia balls as ball milling media. To obtain Gd with a median particle size of 1-9 μm and containing ...

Embodiment 1-6

[0038] Weigh 100 g of commercial Gd with a particle size distribution of d(0.1) of 4.0 μm, d(0.5) of 6.8 μm and d(0.9) of 11.8 μm with a purity of 99.999% 2 o 2 S:Pr, Ce scintillator powder, add 0.2gLi 2 GeF 6 As a sintering aid, put an inner diameter of 100mm in an argon box and a polyurethane ball mill tank with a height of 100mm, add 500g of high-density yttrium oxide reinforced zirconia grinding balls with graded size, place it in a planetary ball mill, and grind it at 500 rpm Under the high speed, the ball milling takes 3 hours, and the interval between forward and reverse running is 0.5 hours.

[0039] The polyurethane ball milling tank and zirconia grinding balls are pre-cleaned. The specific method is as follows: put 500g of high-density yttria-strengthened zirconia grinding balls into the ball milling tank, including 35g of balls with a diameter of 10mm, 105g of balls with a diameter of 6mm, and 360g of balls with a diameter of 3mm. Add 50g of GOS powder, add 500mL...

Embodiment 7-10

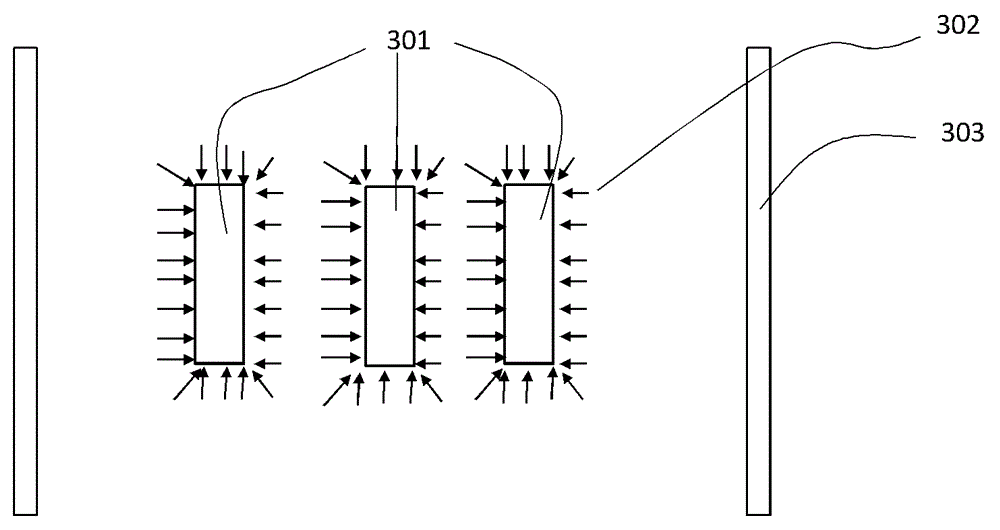

[0044] The scintillation powder was ball milled and mixed in the same manner as in Examples 1-6 to obtain powders with the same particle size distribution. Put the powder into a carbon fiber composite material mold with an inner diameter of 30 mm, and perform primary sintering by discharge plasma. The temperature is 1200-1250°C, the pressure is 200MPa, the vacuum is 1-15Pa, and the heat preservation and pressure are maintained for 2 hours. After the heat preservation is over, perform a cooling program at a cooling rate of 10°C / min, take it out after it is completely cooled to room temperature, and obtain a GOS primary sintered body. The samples of Examples 7 and 8 were subjected to secondary sintering and secondary annealing using the same annealing and hot isostatic pressing methods as in Examples 1-5 to obtain secondary sintered bodies. Examples 9 and 10 only carry out annealing treatment without secondary sintering by hot isostatic pressing. Coarse grinding, fine grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com