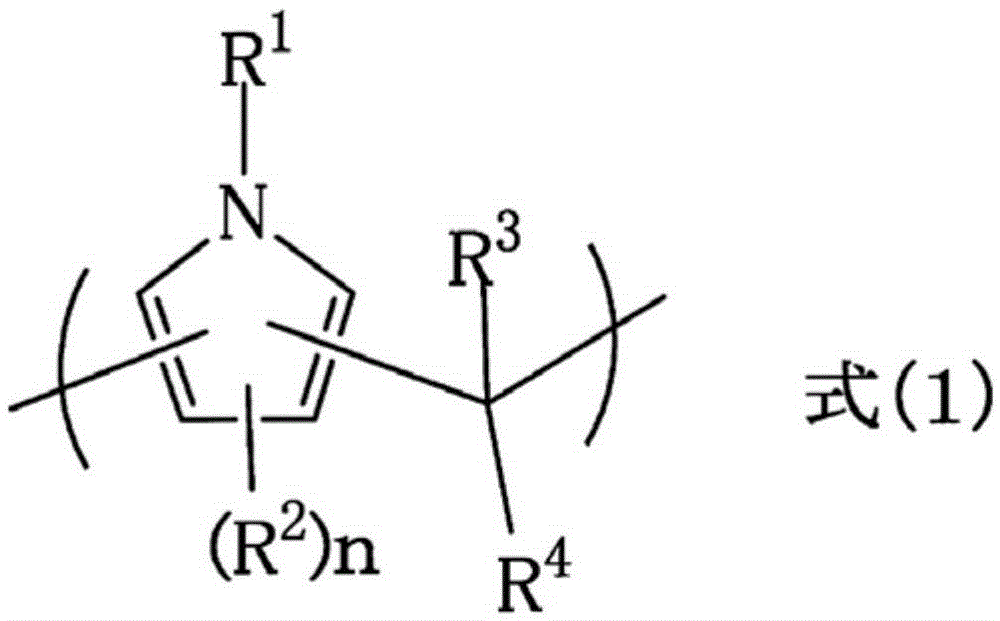

Resist underlayer film forming composition containing pyrrole novolac resin

A technology of resist lower layer and composition, which is applied in the direction of coating, photoplate-making process coating equipment, pattern surface photoplate-making process, etc., can solve the problem that it is difficult to obtain the film thickness of resist pattern, and achieve an etching The effect of patience

- Summary

- Abstract

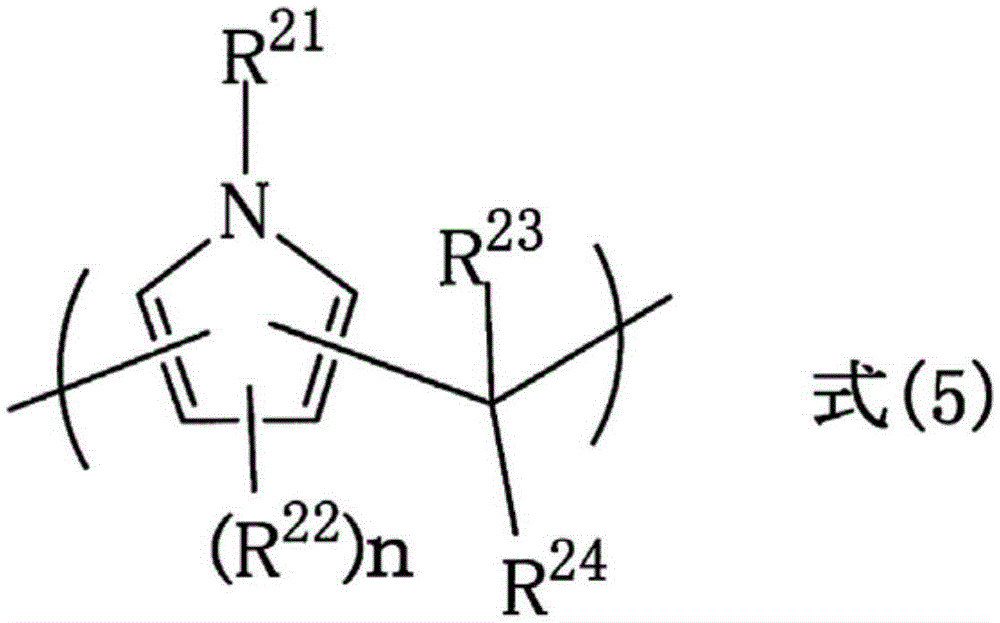

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

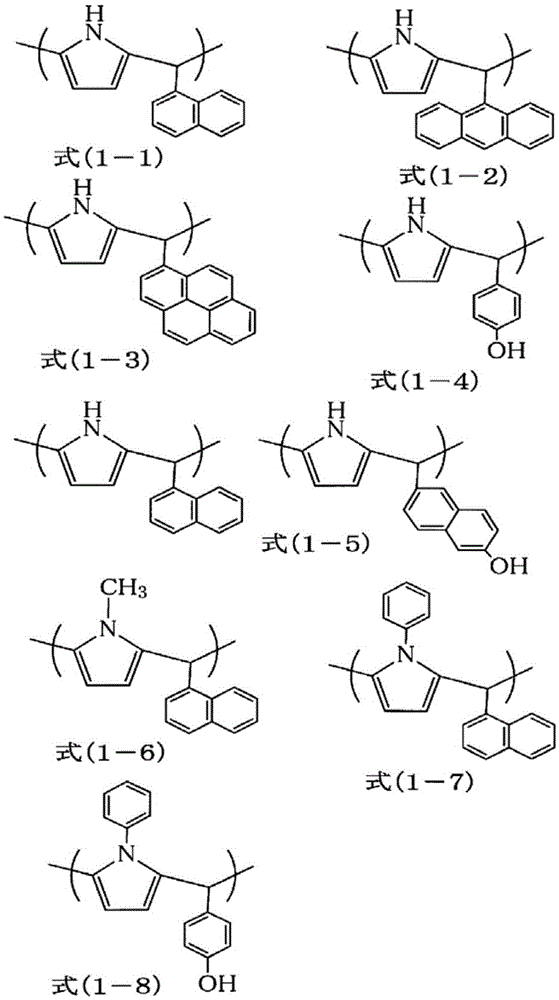

Synthetic example 1

[0104] 6.0 g of pyrrole (manufactured by Tokyo Chemical Industry Co., Ltd.), 14.1 g of 1-naphthaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), and p-toluenesulfonic acid monohydrate (manufactured by Tokyo Chemical Industry Co., Ltd.) were placed in a 100 ml eggplant-shaped flask. manufactured) 1.8 g, and toluene (manufactured by Kanto Chemical Co., Ltd.) 32.8 g. Then, the inside of the flask was replaced with nitrogen, and stirred at room temperature for about 2 hours. After completion of the reaction, it was diluted with 15 g of tetrahydrofuran (manufactured by Kanto Chemical Co., Ltd.). The diluted solution was added dropwise to 1,300 g of methanol (manufactured by Kanto Chemical Co., Ltd.), and reprecipitated. The obtained precipitate was suction-filtered, and the filtrate was washed with methanol, and then dried under reduced pressure at 85° C. overnight to obtain 16.4 g of novolac resin. The resulting polymer corresponds to formula (1-1). The weight avera...

Synthetic example 2

[0106] 6.0 g of pyrrole (manufactured by Tokyo Chemical Industry Co., Ltd.), 18.6 g of 9-anthracene formaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), and p-toluenesulfonic acid monohydrate (manufactured by Tokyo Chemical Industry Co., Ltd.) were added to a 200 ml eggplant-shaped flask. manufactured) 1.8 g, toluene (manufactured by Kanto Chemical Co., Ltd.) 61.6 g. Then, the inside of the flask was replaced with nitrogen, and 6.0 g of pyrrole (manufactured by Tokyo Chemical Industry Co., Ltd.) was added dropwise thereto at room temperature while stirring. After completion of the dropwise addition, the mixture was stirred at room temperature for about 12 hours. After completion of the reaction, the reaction solution was added dropwise to 1,200 g of hexane (manufactured by Kanto Chemical Co., Ltd.), and reprecipitated. The obtained precipitate was suction-filtered, and the filtrate was washed with hexane, and then dried under reduced pressure at 85° C. overnight ...

Synthetic example 3

[0108] 2.0 g of pyrrole (manufactured by Tokyo Chemical Industry Co., Ltd.), 7.0 g of 9-pyrene formaldehyde (manufactured by Tokyo Chemical Industry Co., Ltd.), and p-toluenesulfonic acid monohydrate (manufactured by Tokyo Chemical Industry Co., Ltd.) were placed in a 100 ml eggplant-shaped flask. 0.6 g, toluene (manufactured by Kanto Chemical Co., Ltd.) 28.6 g. Then, the inside of the flask was replaced with nitrogen, and 2.0 g of pyrrole (manufactured by Tokyo Chemical Industry Co., Ltd.) was added dropwise while stirring at room temperature. After completion of the dropwise addition, the mixture was stirred at room temperature for about 1 hour, and then heated and stirred under reflux for about 22 hours. After completion of the reaction, 15 g of tetrahydrofuran (manufactured by Kanto Chemical Co., Ltd.) was added to dissolve the precipitated solid. The solution was added dropwise to 1,200 g of hexane (manufactured by Kanto Chemical Co., Ltd.), and reprecipitated. The obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com