Basic technology of sewage treatment in mining and dressing industry

A sewage treatment and process technology, which is applied in the direction of mining wastewater treatment, adsorption water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of high water content, non-stirring, and large dosage of sludge produced, and achieve The effect of reducing comprehensive operating costs, ensuring stability, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The treatment of embodiment 1-certain enterprise mining mining waste water:

[0062] The raw water and post-treatment requirements of the water body are:

[0063]

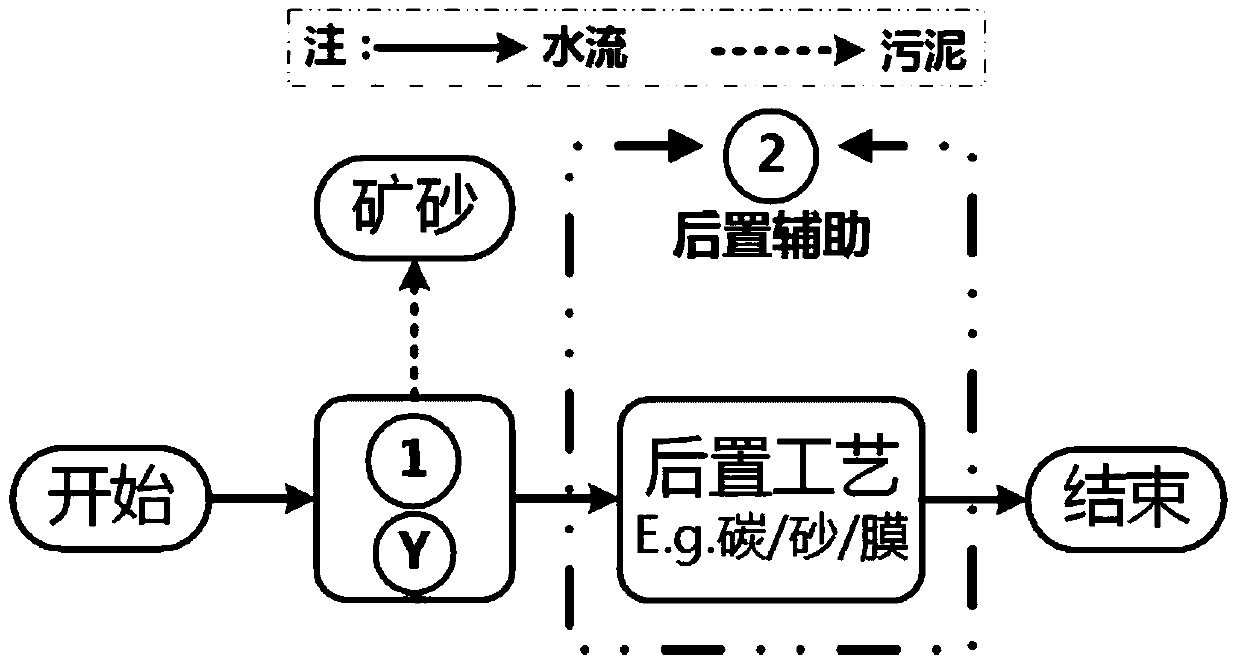

[0064] Based on the present invention "a basic process for sewage treatment in the mining and dressing industry", the process flow diagram for this embodiment is as follows figure 1 As shown, the process includes ① the core process of sewage treatment, ② sub-processes such as post-installation auxiliary processes. The detailed sub-process and each process point process, parameters, control and operation method steps are described as follows:

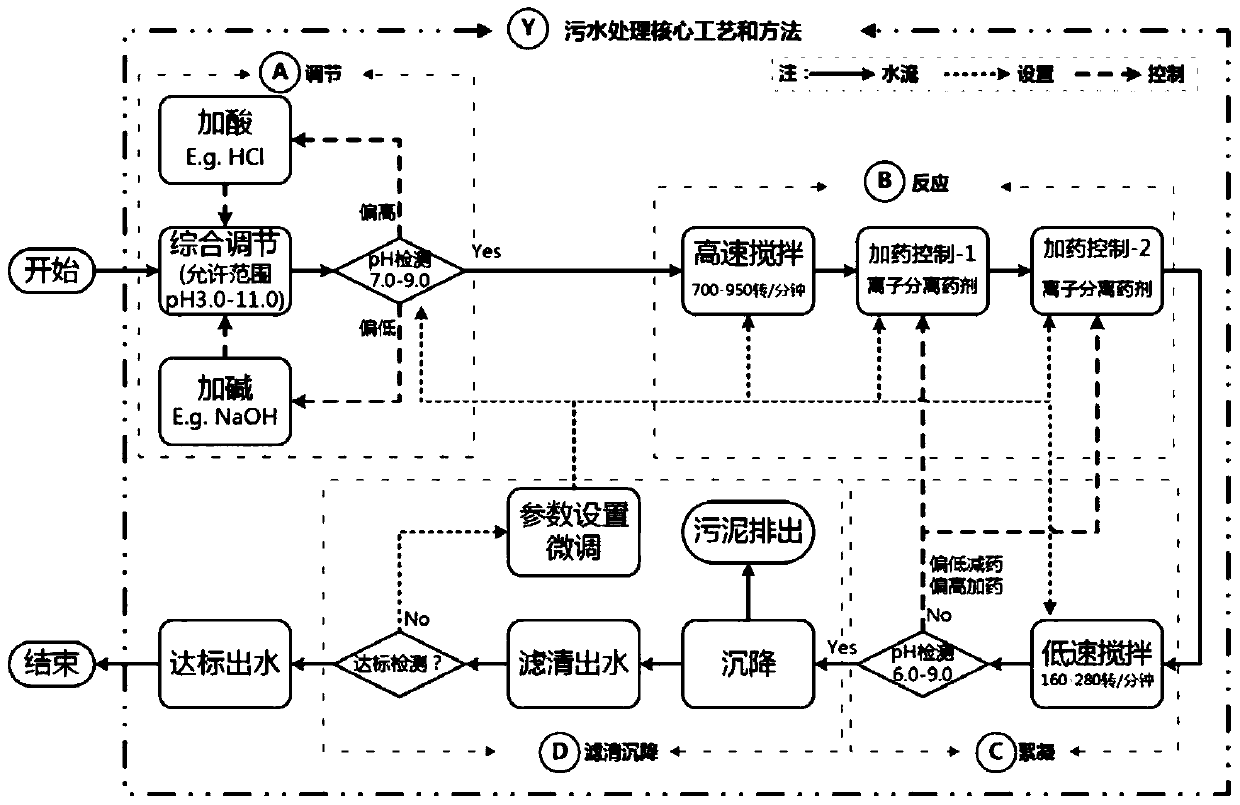

[0065] ①Sewage treatment core process and method sub-process The process flow chart is as figure 2 shown, including adjust, reaction, Flocculation and Four sub-processes such as filtration and sedimentation. The sub-process and each process point process, parameters, control and operation method steps are described as follows:

[0066] A. Adjustment: ...

Embodiment 2

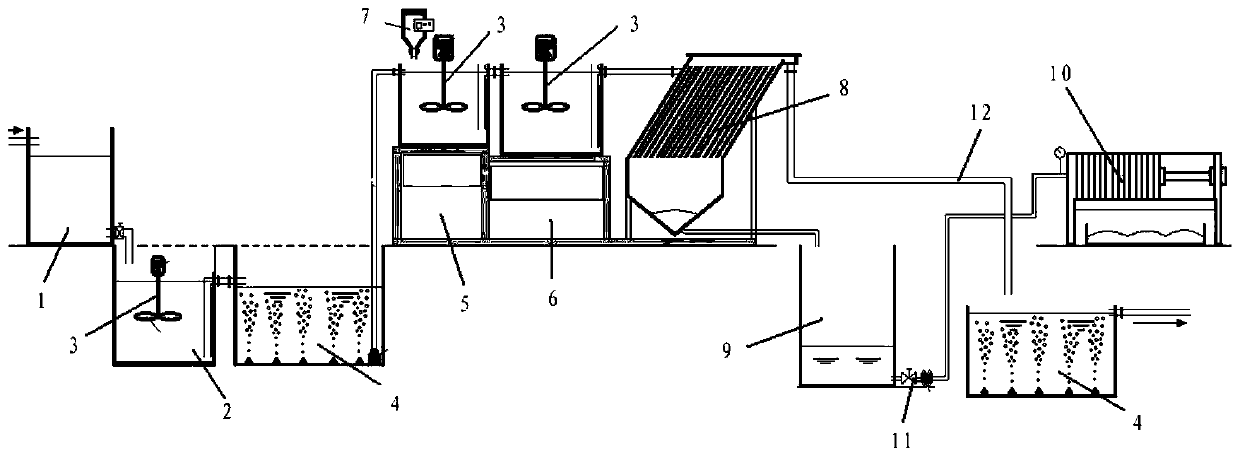

[0099] Process step of the present invention can be in image 3 and Figure 4 It is carried out in the mobile integrated complete set of equipment involved. The specific processing steps of the mobile integrated complete set of equipment are as follows:

[0100] (1) In order to cooperate with the ion separation agent to achieve a good chemical reaction effect, first put the sewage into the pH adjustment tank, and add a pH regulator suitable for different sewage at the same time, usually for acidification;

[0101] (2) After the pH value of the sewage is adjusted by the pH adjustment tank, it enters the adjustment tank 2, and the pH value of the acidified water body is adjusted to 7.0-9.0. In order to mix evenly, it can be stirred with an agitator;

[0102] (3) In order to further fully mix and react, and achieve the purpose of breaking the molecular chain of sewage or releasing corresponding substances, the sewage and corresponding chemicals after passing through the adjustm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com