A kind of preparation method of Cu-Fe molecular sieve catalyst for diesel vehicle exhaust

A molecular sieve and diesel vehicle technology, applied in the field of catalyst preparation for SCR denitration, can solve the problems of inability to meet emission regulations, narrow catalyst temperature window, environmental and human hazards, etc. The effect of high load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 454g of Cu(NO 3 ) 2 ﹒ 3H 2 O and 758g Fe(NO 3 ) 3 ﹒ 9H 2 O in 4000g deionized water, mix and stir until dissolved; add 3000g ZSM-5 molecular sieve and 100g ethanol, after mixing and stirring for 4h, add 980g of ammonia water with a mass fraction of 25%, mix and stir for 3h; add 400g of copper oxide powder whose D90 is 500nm , mixed and stirred, impregnated statically for 2 hours; put it into a disk and dry it in an oven at 105°C, crush the dried massive solid with a pulverizer, put it in a muffle furnace for calcination at 480°C for 6 hours, and put the calcined powder The body was further processed into a powder with a particle size D50 of 500nm by a grinder, and a Cu-Fe molecular sieve catalyst for diesel vehicle exhaust was obtained.

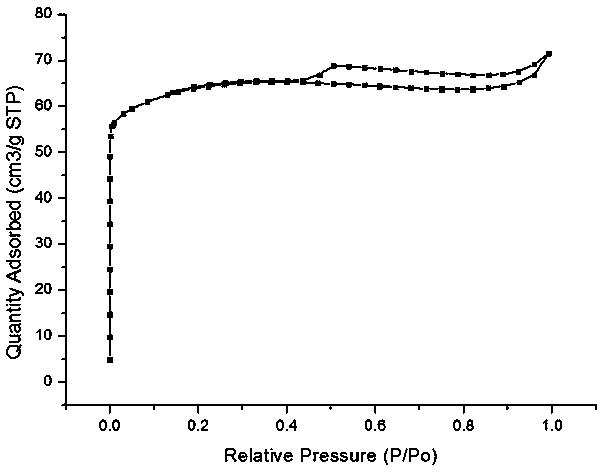

[0021] Tested by nitrogen isotherm adsorption-desorption curve, see figure 1 , conforming to the H4-type slit-hole hysteresis loop of the Kelvin equation in the four types of hysteresis loops classified according to IUPAC...

Embodiment 2

[0034] Weigh 907g of Cu(NO 3 ) 2 ﹒ 3H 2 O and 1515g Fe(NO 3 ) 3 ﹒ 9H 2 O in 8005g deionized water, mix and stir to dissolve; add 3000g ZSM-5 molecular sieve and 300g isobutanol, mix and stir for 8 hours, add 1500g of ammonia water with a mass fraction of 28%, mix and stir for 5 hours; add 50g of manganese oxide whose D90 is 3000nm Powder, mixed and stirred, impregnated statically for 4 hours; placed in a disk and dried in an oven at 150°C, crushed the dried block solid in a pulverizer, placed in a muffle furnace for calcination at 550°C for 4 hours, and the calcined The powder is further processed into a powder with a particle size D50 of 2000nm by a grinder to obtain a Cu-Fe molecular sieve catalyst for diesel vehicle exhaust.

Embodiment 3

[0036] Weigh 500g of Cu(CH 3 COO) 2 ﹒ h 2 O and 505g Fe(NO 3 ) 3 ﹒ 9H 2 O in 6000g deionized water, mix and stir to dissolve; add 3000g SSZ-13 molecular sieve and 200g n-butanol, mix and stir for 4 hours, add 980g of ammonia water with a mass fraction of 25%, mix and stir for 5 hours; add 300g of cobalt oxide whose D90 is 1000nm Powder, mixed and stirred, impregnated statically for 4 hours; placed in a disk and dried in an oven at 120°C, crushed the dried block solid in a pulverizer, placed in a muffle furnace for calcination at 550°C for 4 hours, and the calcined The powder is further processed into a powder with a particle size D50 of 2000nm by a grinder to obtain a Cu-Fe molecular sieve catalyst for diesel vehicle exhaust.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com