Preparation method of ultra-high-precision silicon-based through-hole pattern structure

A patterned, sophisticated technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of easy deformation, high cost, and reduced etching rate of silicon nitride through-hole thin films, and achieve fast and large-scale production. , low cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention mainly proposes a method for preparing an ultra-high-precision silicon-based through-hole pattern structure, which includes the following steps:

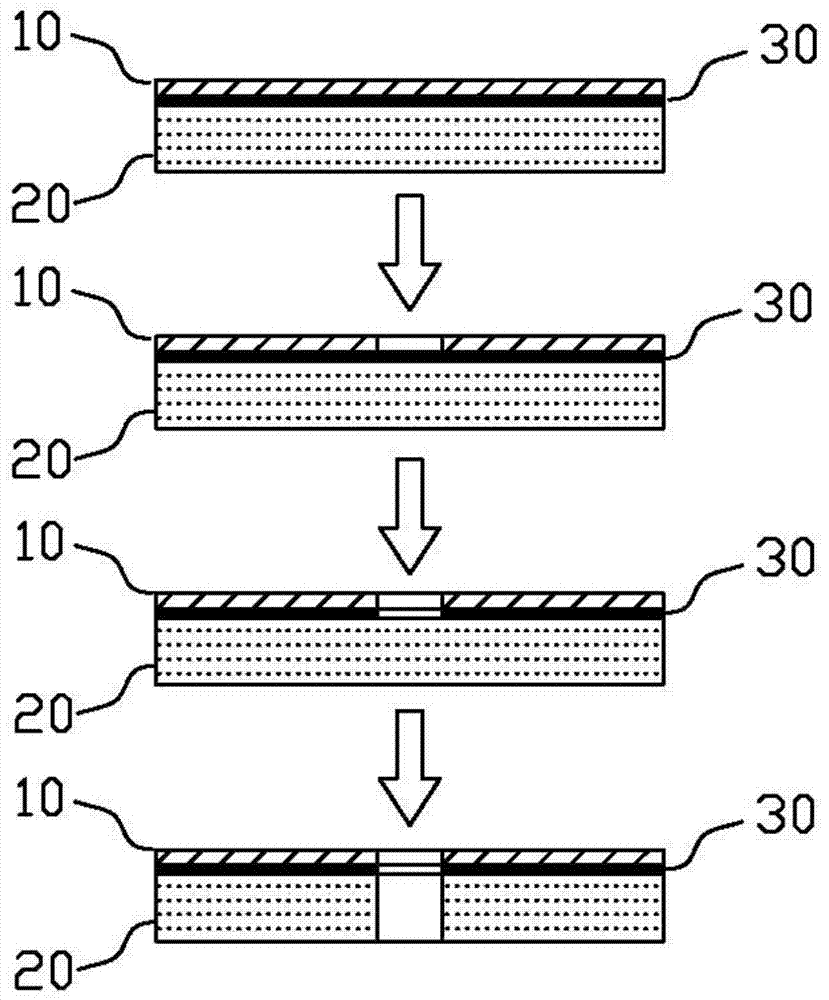

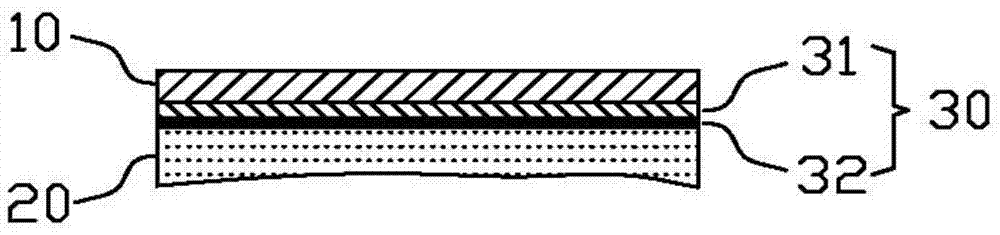

[0032] Fabricate an inorganic mask layer on the silicon substrate;

[0033] Coating photoresist on the inorganic mask layer, and etching to form a photoresist pattern structure;

[0034] Etching the inorganic mask layer by using the photoresist pattern structure as a mask;

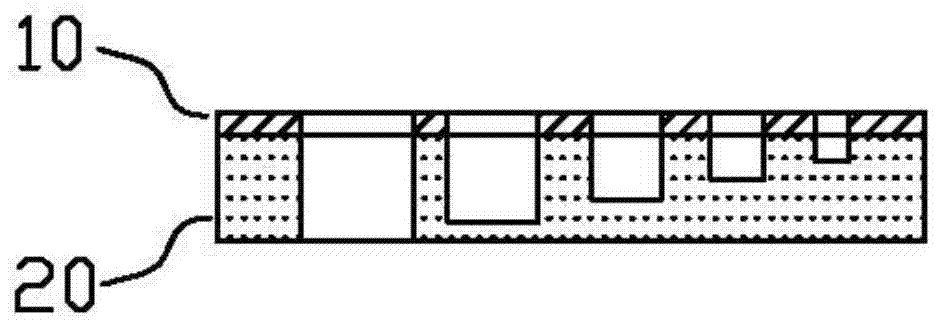

[0035] Using the etched inorganic mask layer as a mask, a dry etching process is used to etch the silicon substrate to form a pattern structure of through holes on the silicon substrate.

[0036] Further, in the dry etching process, for openings with a diameter of less than 2 μm, the silicon etching selectivity ratio of the inorganic mask layer at room temperature is above 1:1000, and the silicon substrate Before the etching depth of the area corresponding to the minimum aperture in the through-hole pattern structure reaches a set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com