Core-shell structured carbon-silicon carbide composite nano-fibers based on coaxial electrostatic spinning process and preparation method thereof

A technology of coaxial electrospinning and composite nanofibers is applied in spinning solution preparation, fiber processing, fiber chemical characteristics, etc. The effect of overcoming inherent defects and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

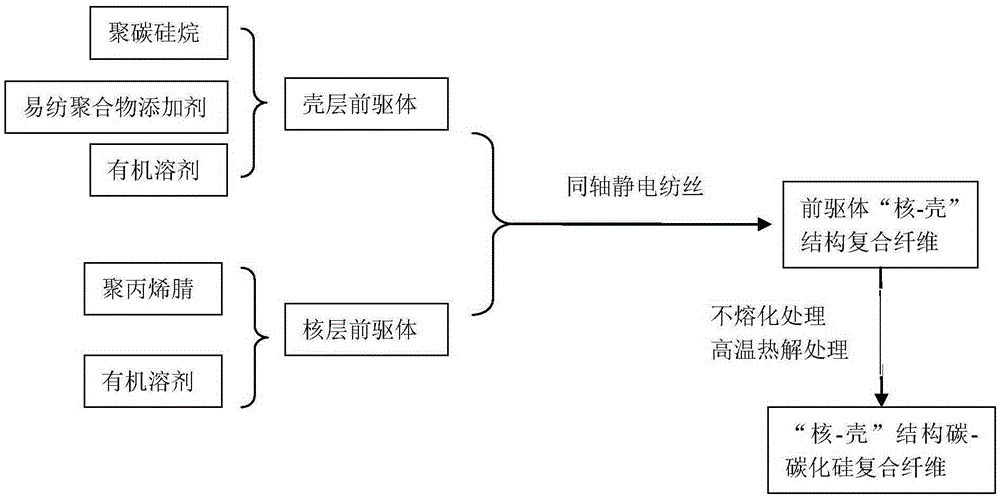

Method used

Image

Examples

Embodiment 1

[0045] (1) Weigh 2g of PCS and 1g of polycaprolactone and dissolve them in 10ml of chloroform and magnetically stir for 12h to form a uniform shell precursor spinning solution.

[0046] (2) 1 g of PAN was weighed and dissolved in N,N-dimethylformamide and magnetically stirred in a water bath at 80° C. for 1 h to form a homogeneous core layer precursor spinning solution.

[0047] (3) The solution in step (1) is used as the spinning solution for the shell layer of the outer tube, and the solution in the step (2) is used as the spinning solution for the core layer of the inner tube for coaxial spinning. The advancing speed of the outer tube is 1.35ml / h, the advancing speed of the inner tube is 0.9ml / h, the spinning voltage is 15kV, the distance between the nozzle and the collector is 20mm, the inner diameter of the needle of the shell layer is 1.25mm, and the inner diameter of the needle of the core layer is 0.9mm. The collector type is a vertical flat collector.

[0048] (4) Pu...

Embodiment 2

[0051] (1) Dissolve 2.5g PCS and 1g polystyrene in 10ml tetrahydrofuran and magnetically stir for 12h to form a uniform shell precursor spinning solution.

[0052] (2) 1 g of PAN was weighed and dissolved in N,N-dimethylformamide and magnetically stirred in a water bath at 80° C. for 1 h to form a homogeneous core layer precursor spinning solution.

[0053] (3) The solution in step (1) is used as the spinning solution for the shell layer of the outer tube, and the solution in the step (2) is used as the spinning solution for the core layer of the inner tube for coaxial spinning. The advancing speed of the outer tube is 1.35ml / h, the advancing speed of the inner tube is 0.9ml / h, the spinning voltage is 15kV, the distance between the nozzle and the collector is 20mm, the inner diameter of the needle of the shell layer is 1.25mm, and the inner diameter of the needle of the core layer is 0.9mm. The collector type is a horizontal plate collector.

[0054] (4) Put the precursor com...

Embodiment 3

[0057] (1) Weigh 2g of PCS and 1g of polycaprolactone and dissolve in a mixed solvent composed of 7ml of chloroform and 3ml of N,N-dimethylformamide and magnetically stir for 12h to form a uniform shell precursor spinning solution.

[0058] (2) Dissolve 1.5 g of PAN in N, N-dimethylformamide and magnetically stir in a water bath at 80° C. for 1 h to form a uniform spinning solution of the core layer precursor.

[0059] (3) The solution in step (1) is used as the spinning solution for the shell layer of the outer tube, and the solution in the step (2) is used as the spinning solution for the core layer of the inner tube for coaxial spinning. The advancing speed of the outer tube is 2.7ml / h, the advancing speed of the inner tube is 1.35ml / h, the spinning voltage is 25kV, the distance between the nozzle and the collector is 20mm, the inner diameter of the shell needle is 1.25mm, and the inner diameter of the nuclear needle is 0.9mm. The collector type is a vertical flat collector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com