One-component moisture cured polyurethane sealant excellent in weather resistance and preparation method thereof

A polyurethane sealant, moisture curing technology, applied in chemical instruments and methods, other chemical processes, adhesive additives, etc., can solve the problems of polyurethane sealant yellowing, poor weather resistance, colloidal surface cracks, etc., to achieve mechanical Slow performance attenuation, excellent yellowing resistance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

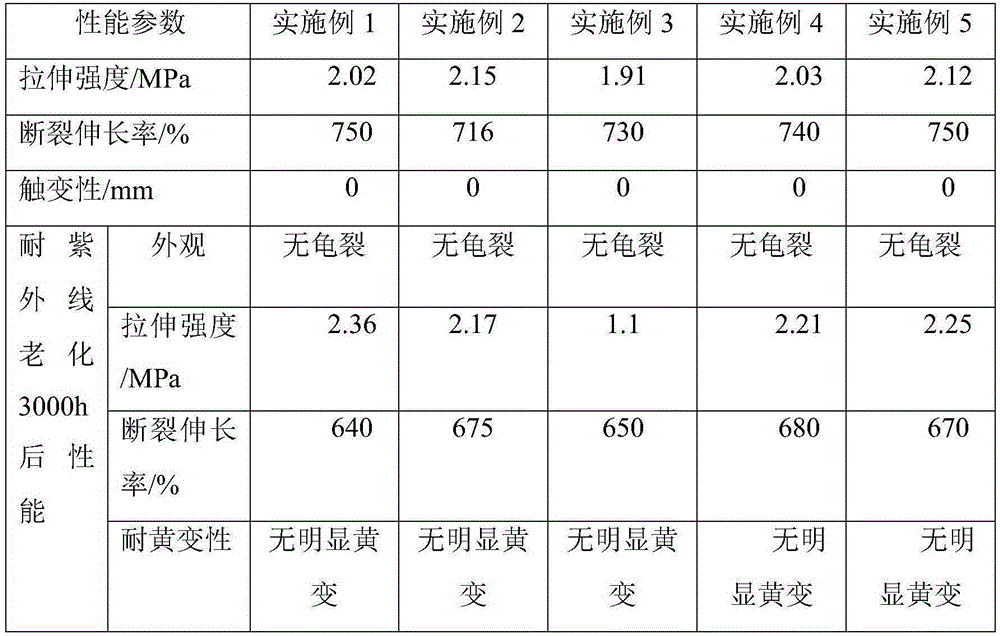

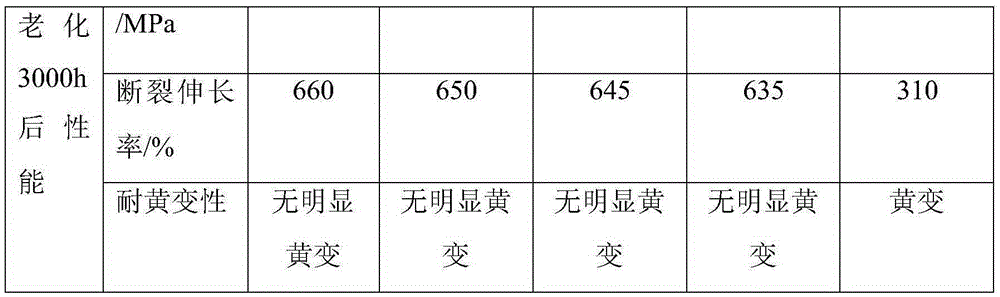

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a preparation method of the above-mentioned one-component moisture-curing polyurethane sealant with excellent weather resistance, comprising the following steps:

[0032] The environment for producing and packaging the polyurethane sealant should be controlled at a temperature of ≤25°C and a relative humidity of ≤55%RH;

[0033] Preparation of polyurethane prepolymer: In terms of parts by mass, add 20-65 parts of polyether polyol to a dry three-necked flask, vacuumize at 120°C, dehydrate for 0.5-1h, cool down to about 60°C, add 5- 30 parts of aliphatic or alicyclic isocyanate, 0.01-0.05 parts of the second catalyst, 0-7 parts of diluent, the second catalyst is dibutyltin dilaurate, stannous octoate, dibutyltin diacetate, 2,2- Any one of bismorpholinyl diethyl ether and 1,8-diazacycloundecene; slowly raise the temperature to 80°C, keep the temperature for 3 hours under the protection of dry nitrogen, and discharge the...

Embodiment 1

[0050] This embodiment provides a one-component moisture-curing polyurethane sealant with excellent weather resistance. In terms of parts by mass, the polyurethane sealant includes 34.5 parts of polyurethane prepolymer, 0.8 part of toluenesulfonyl isocyanate, and 0.3 part of γ-shrinkage Glyceryl ether oxypropyl trimethoxysilane, 0.6 parts of UV327, 0.3 parts of Irganox1098, 4 parts of titanium dioxide, 43 parts of calcium carbonate, 16 parts of polyurea, 0.8 parts of lead octoate; among them, the polyurethane prepolymer includes 27 parts of polyether di Alcohol Tdiol-2000, 13 parts of polyether triol GEP-330N, 8 parts of 4,4'-dicyclohexylmethane diisocyanate, 0.01 part of dibutyltin dilaurate, 2 parts of toluene.

[0051] The preparation method of the above-mentioned one-component moisture-curing polyurethane sealant with excellent weather resistance comprises the following steps:

[0052] The environment for producing and packaging the polyurethane sealant should be controlle...

Embodiment 2

[0056] This embodiment provides a one-component moisture-curing polyurethane sealant with excellent weather resistance. In terms of parts by mass, the polyurethane sealant includes 34.5 parts of polyurethane prepolymer, 0.8 part of toluenesulfonyl isocyanate, and 0.3 part of γ-shrinkage Glyceryl ether oxypropyl trimethoxysilane, 0.8 parts of LA-62, 0.5 parts of Irganox1098, 8 parts of titanium dioxide, 43 parts of polyvinyl chloride paste resin, 16 parts of hydrophobic fumed silica, 0.8 parts of dibutyltin dilaurate; Among them, 27 parts of polyurethane prepolymer polyether diol Tdiol-2000, 13 parts of polyether triol GEP-330N, 8 parts of 4,4'-dicyclohexylmethane diisocyanate, 0.01 part of dibutyltin dilaurate, 2 parts toluene.

[0057] The preparation method of the above-mentioned one-component moisture-curing polyurethane sealant with excellent weather resistance comprises the following steps:

[0058] The environment for producing and packaging the polyurethane sealant sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com