Preparation method of decoquinate

A technology of decoquinate and sodium hydroxide, which is applied in the field of poultry medicine preparation technology, can solve the problems of high reaction temperature, high equipment requirements, and easy spraying of materials, and achieve high selectivity, short process route, and no corrosion The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

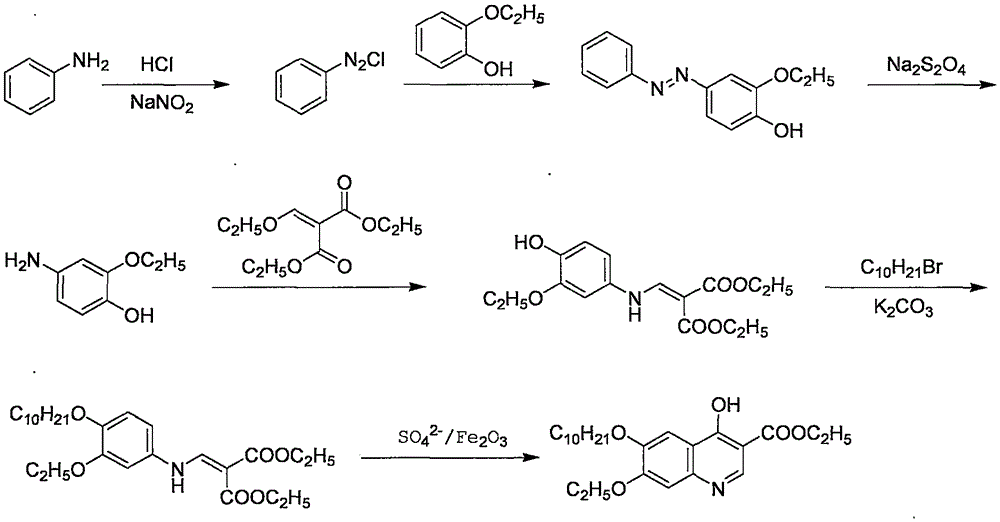

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a preparation method of decoquinate, comprising the following steps:

[0021] S1, diazotization

[0022] Put 7.5 parts of aniline and 22 parts of water into the reaction kettle, cool down to 0°C, stir slowly, add 21 parts of 30-32% concentrated hydrochloric acid, after the addition is completed, the temperature drops to 0°C, and then add sodium nitrite solution (5.9 part, 22 parts of water), after the flow addition is completed, continue to react at this temperature for 1h to obtain the diazonium salt solution of aniline, which is kept at low temperature for sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com