Reactor shielding layer component with high density and large neutron-absorption cross section

A shielding layer and high-density technology, applied in the field of nuclear engineering, can solve the problems of reactor safety uncertainty, shielding layer component installation, fixation and replacement problems, low density of boron carbide pellets, etc., to achieve small neutron capture area change, The effect of less loss of physical value and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

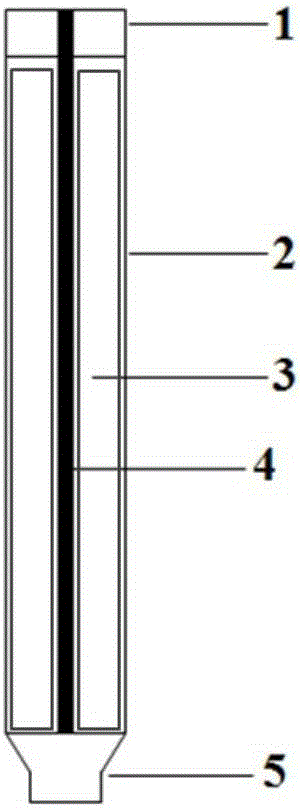

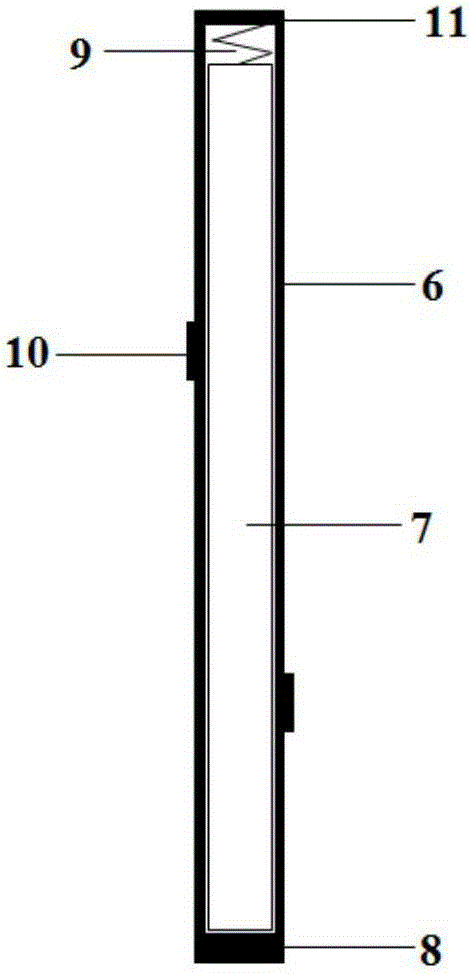

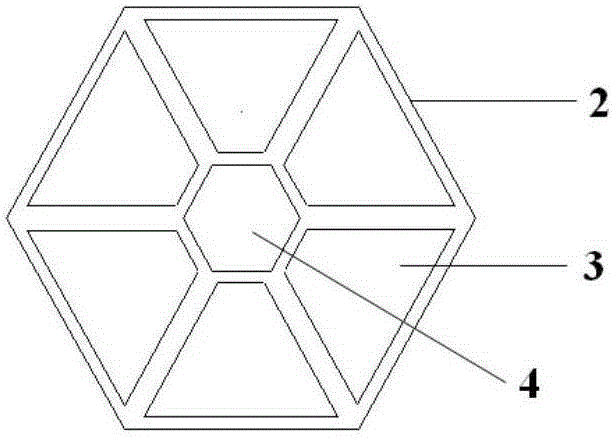

[0029] Such as figure 1 , figure 2 As shown, the shielding layer assembly of the present invention includes: an operating head 1, an outer sleeve 2, a neutron shielding block 3, a connecting rod 4, and a lower pin 5; the upper end of the shielding layer assembly is the operating head 1, and the lower end is the lower tube The pin 5, the operating head 1 and the lower pin 5 are connected through the outer sleeve 2; the outer sleeve 2 is a regular hexagonal hollow cylinder, and the center is a connecting rod 4, and the connecting rod 4 is fixedly connected with the operating head 1 and the lower pin 5; the outer sleeve A neutron shielding block 3 is arranged between the tube 2 and the connecting rod 4; the neutron shielding block 3 is fixedly connected to the lower pin 5, and the outer wall of the neutron shielding block 3 contains a spacer 10; between the neutron shielding blocks 3, the outer casing 2 and the neutron shielding block 3, between the connecting rod 4 and the neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com