N-methyl diisopropanolamine preparation method

A technology of methyldiisopropanolamine and diisopropanolamine, applied in the field of preparation of N-methyldiisopropanolamine, can solve the problem of low conversion rate and low purity of N-methyldiisopropanolamine and other problems, to achieve the effect of high conversion rate, avoiding deamination reaction, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

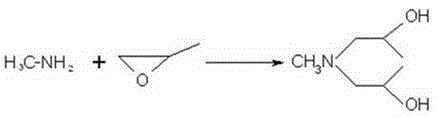

Image

Examples

Embodiment 1

[0024] (1) Add 266g of diisopropanolamine and 60g of paraformaldehyde (polymerization degree: 200) into a four-necked flask equipped with a mechanical stirrer and a thermometer, stir evenly, heat, control the reaction temperature at 60°C, and evacuate to The vacuum degree in the reactor is -0.090~-0.099MPa. After stirring and reacting for 2 hours, an intermediate product is obtained, which is a colorless transparent liquid. Sampling is carried out for gas chromatography analysis, and the yield of the intermediate product is 95.1%;

[0025] (2) Cool 50g of the intermediate product obtained in step (1) to room temperature, add 100g of methanol for dilution to obtain the diluted product; (3) add the diluted product to the reaction kettle, and then add 2.5g of Raney nickel , 4g triethylamine, replace the air in the reactor with 1.5Mpa hydrogen for 3-4 times, fill the reactor with hydrogen to 2Mpa, stir the reaction, and control the reaction temperature at about 45°C through circula...

Embodiment 2

[0027] (1) Add 266g of diisopropanolamine and 60g of paraformaldehyde (polymerization degree: 200) into a four-necked flask equipped with a mechanical stirrer and a thermometer, stir evenly, heat, control the reaction temperature at 70°C, and evacuate to The vacuum degree in the reactor is -0.090~-0.099MPa. After stirring and reacting for 2 hours, the intermediate product is obtained as a colorless transparent liquid. Samples are taken and analyzed by gas chromatography. The yield of the intermediate product is 96.3%;

[0028] (2) Cool 50g of the intermediate product obtained in step (1) to room temperature, add 150g of isopropanol for dilution, and obtain the diluted product;

[0029] (3) Add the diluted product to the reactor, then add 2.5g of copper chromite and 4g of trimethylamine, replace the air in the reactor with 1.5Mpa hydrogen for 3-4 times, then fill the reactor with hydrogen to 2Mpa, stir the reaction, and control the reaction temperature at about 45°C by circulat...

Embodiment 3

[0031] (1) Add 266g of diisopropanolamine and 63g of paraformaldehyde (polymerization degree: 200) into a four-necked flask equipped with a mechanical stirrer and a thermometer, stir evenly, heat, control the reaction temperature at 70°C, and evacuate to The vacuum degree in the reactor is -0.090~-0.099MPa. After stirring and reacting for 3 hours, an intermediate product is obtained, which is a colorless transparent liquid. Samples are taken and analyzed by gas chromatography. The yield of the intermediate product is 99.5%;

[0032] (2) Cool 50g of the intermediate product obtained in step (1) to room temperature, add 150g of isopropanol for dilution, and obtain the diluted product;

[0033] (3) Add the diluted product to the reactor, then add 2.5g of copper chromite and 4g of trimethylamine, replace the air in the reactor with 1.5Mpa hydrogen for 3-4 times, then fill the reactor with hydrogen to 2Mpa, stir the reaction, and control the reaction temperature at about 45°C by ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com