Al2O3/Ti(C,N) composite ceramic tool material and microwave sintering process thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

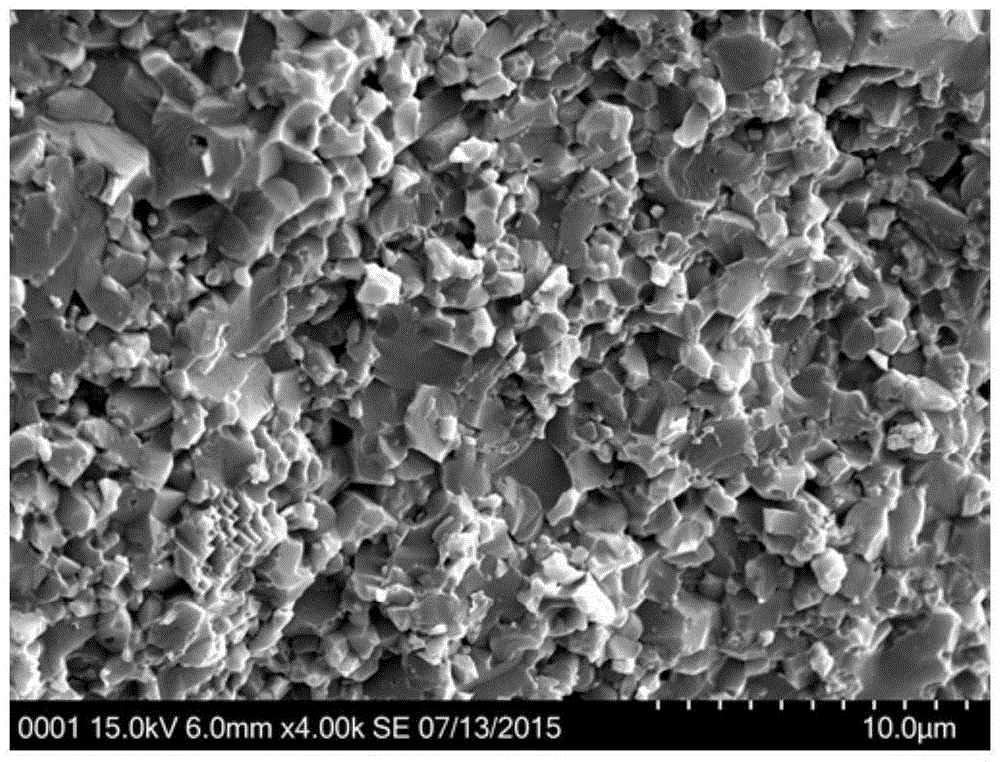

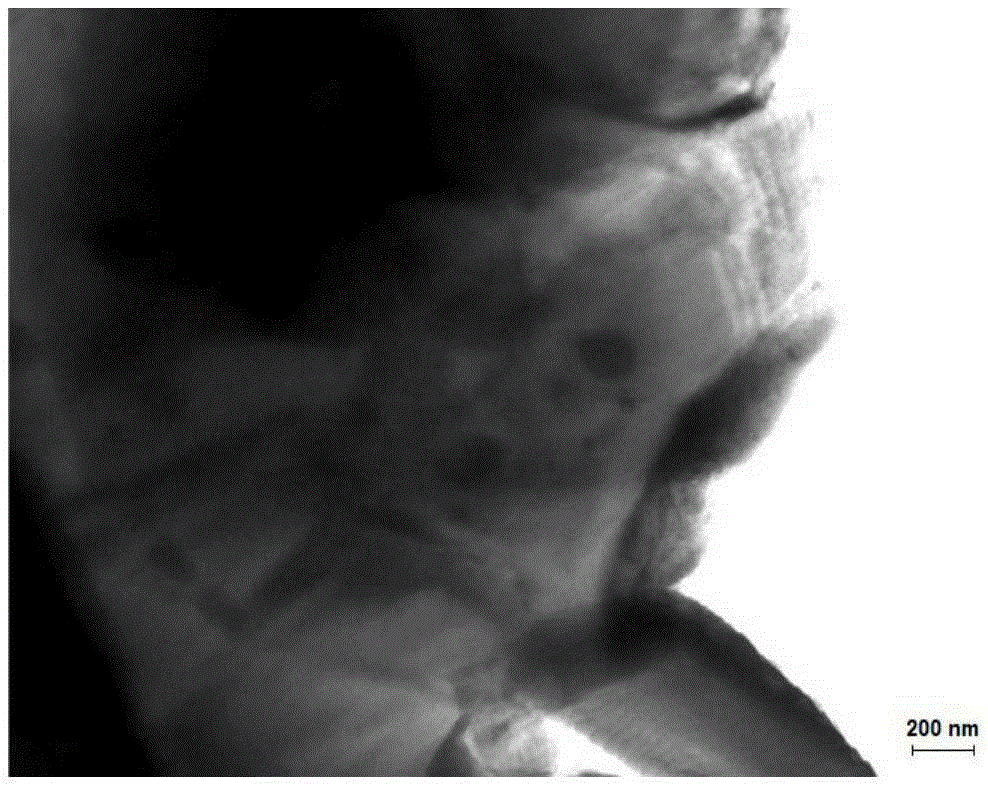

Image

Examples

Embodiment 1

[0024] Press Al 2 o 3 1.875g, Ti(C,N)0.5g, Ni0.075g, Mo0.05g are batched; the powder after weighing is put into the planetary ball mill, and the medium is ball milled with an alumina ball for 24 hours with anhydrous ethanol; 2 hours before the end, add polyvinyl alcohol solution with a concentration of 3% to the mixed powder, and the quality of polyvinyl alcohol is 1% of the mixed powder mass; the mixed material after ball milling is dried, ground and sieved; the sieved powder One-way pressure compression molding, molding pressure 200MPa, pressure holding time 2min; under nitrogen atmosphere, microwave sintering was carried out in a microwave sintering furnace with a frequency of 2.45GHz, and the temperature was raised to 1500°C at a heating rate of 30°C / min. Keep it warm for 5 minutes, then cool down to room temperature with the furnace.

Embodiment 2

[0026] Press Al 2 o 3 1.75g, Ti(C,N)0.625g, Ni0.075g, Mo0.05g are carried out batching; The powder after weighing is packed in the planetary ball mill, with anhydrous ethanol as medium use alumina ball mill for 48 hours; 2 hours before the end, add polyvinyl alcohol solution with a concentration of 5% to the mixed powder, and the quality of polyvinyl alcohol is 5% of the mixed powder mass; the mixed material after ball milling is dried, ground and sieved; the sieved powder One-way pressure compression molding, molding pressure 200MPa, pressure holding time 2min; under nitrogen atmosphere, use 2.45GHz frequency microwave sintering furnace for microwave sintering, and raise the temperature to 1500℃ at a heating rate of 40℃ / min, at this temperature Keep it warm for 10 minutes, then cool down to room temperature with the furnace.

Embodiment 3

[0028] Press Al 2 o 31.75g, Ti(C,N)0.625g, Ni0.075g, Mo0.05g are carried out batching; The powder after weighing is packed in the planetary ball mill, with anhydrous ethanol as medium use alumina ball mill for 48 hours; 3 hours before the end, add polyvinyl alcohol solution with a concentration of 3% to the mixed powder, and the quality of polyvinyl alcohol is 3% of the mixed powder mass; the mixed material after ball milling is dried, ground and sieved; the sieved powder One-way pressure compression molding, molding pressure 300MPa, pressure holding time 2min; under nitrogen atmosphere, microwave sintering was carried out in a microwave sintering furnace with a frequency of 2.45GHz, and the temperature was raised to 1550°C at a heating rate of 40°C / min. Keep it warm for 15 minutes, then cool to room temperature with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com