Preparation method of catalyst for preparing propene through propane dehydrogenation

A propane dehydrogenation and catalyst technology, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of pollution and high product cost, and achieve the effects of cleaning the preparation process, reducing the preparation cost, and reducing the calcination temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

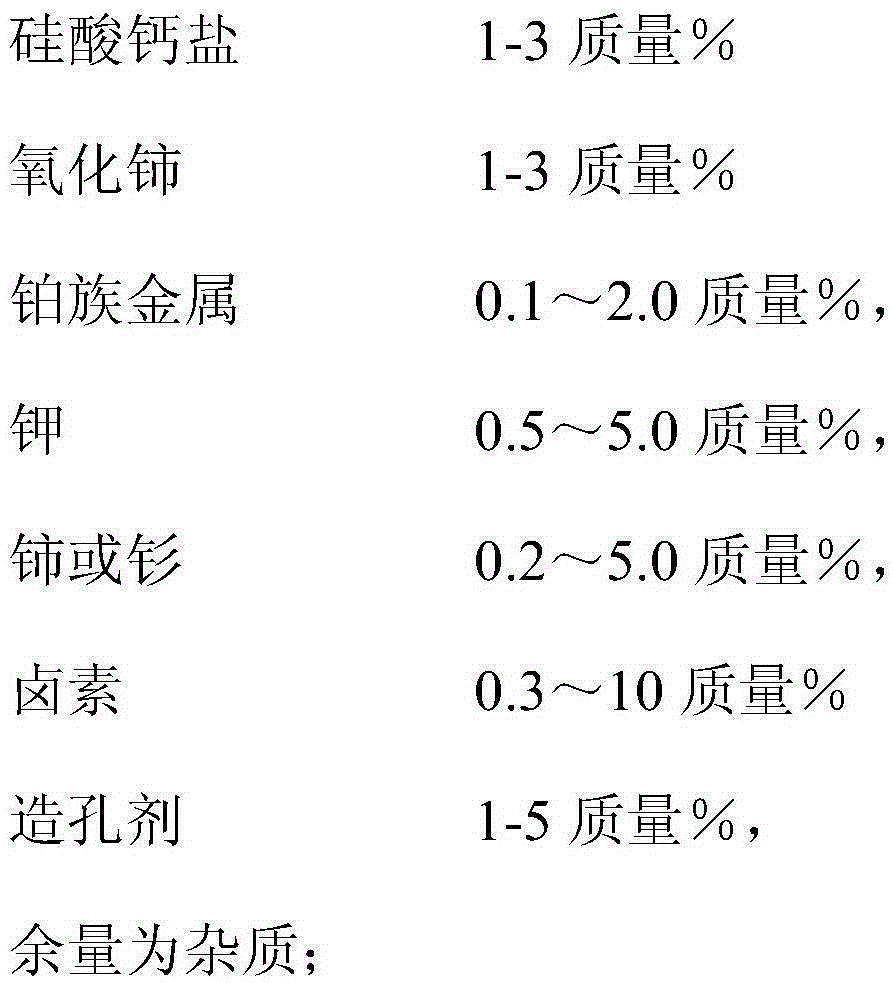

[0020] A method for preparing a catalyst for propane dehydrogenation to propylene, comprising an alumina carrier and an active component whose content is as follows based on the carrier:

[0021]

[0022]

[0023] The molar ratio of cerium or samarium to the platinum group metal is 7:8; the platinum group metal is platinum; the halogen is chlorine;

[0024] The alumina carrier is impregnated with a soluble cerium or samarium compound solution, a calcium silicate salt solution, dried, calcined, and then impregnated with a platinum group metal compound and hydrogen halide solution, dried, calcined, and then impregnated with a potassium salt solution. Drying and calcining; then mixing the above corresponding amount of cerium oxide and pore-forming agent, calcining at 600°C for 3 hours to obtain the catalyst for propane dehydrogenation to propylene.

Embodiment 2

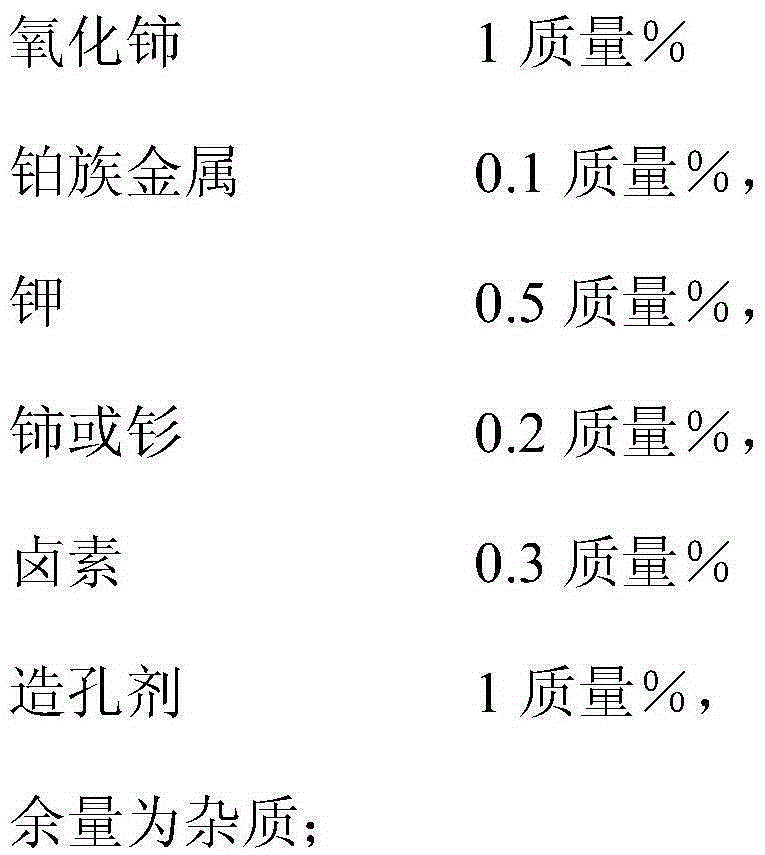

[0026] A method for preparing a catalyst for propane dehydrogenation to propylene, comprising an alumina carrier and an active component whose content is as follows based on the carrier:

[0027]

[0028] The molar ratio of cerium or samarium to the platinum group metal is 7:8; the platinum group metal is platinum; the halogen is chlorine;

[0029] The alumina carrier is impregnated with a soluble cerium or samarium compound solution, a calcium silicate salt solution, dried, calcined, and then impregnated with a platinum group metal compound and hydrogen halide solution, dried, calcined, and then impregnated with a potassium salt solution. Drying and calcining; then mixing the above corresponding amount of cerium oxide and pore-forming agent, calcining at 600°C for 3 hours to obtain the catalyst for propane dehydrogenation to propylene.

Embodiment 3

[0031] A method for preparing a catalyst for propane dehydrogenation to propylene, comprising an alumina carrier and an active component whose content is as follows based on the carrier:

[0032]

[0033] The molar ratio of cerium or samarium to the platinum group metal is 7:8; the platinum group metal is platinum; the halogen is chlorine;

[0034] The alumina carrier is impregnated with a soluble cerium or samarium compound solution, a calcium silicate salt solution, dried, calcined, and then impregnated with a platinum group metal compound and hydrogen halide solution, dried, calcined, and then impregnated with a potassium salt solution. Drying and calcining; then mixing the above corresponding amount of cerium oxide and pore-forming agent, calcining at 600°C for 3 hours to obtain the catalyst for propane dehydrogenation to propylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com