Method for producing lining plate of ball mill by adopting rolling technology

A ball mill liner and process technology, applied in the field of ball mill liner, can solve the problems of affecting the mechanical strength and wear resistance of the liner, high labor intensity of workers, low production efficiency, etc., so as to improve production efficiency and economic benefit and reduce labor. Strength and production cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

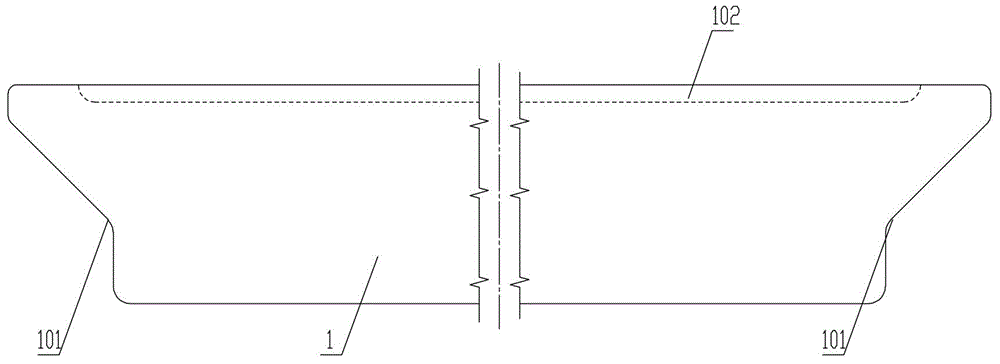

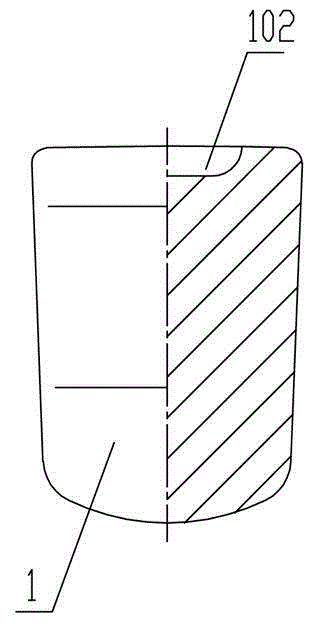

[0027] Take the ball mill liner used in the Φ2700×3600 ball mill used in the current mine concentrator as an example.

[0028] The present invention comprises the following steps:

[0029] (1) Smelting, putting scrap steel materials into an intermediate frequency electric furnace for smelting, the melting temperature is: 1600°C;

[0030] (2) Batching, sampling and testing the molten steel in the intermediate frequency electric furnace, detecting the content of each element in the molten steel, and disposing a certain amount of trace elements in the molten steel until the weight percentage of each element in the molten steel reaches the following requirements: C0.30 %, Mn0.90%, Si0.90%, Ni1.0%, Cr0.90%, Mo0.20%, S0.025%, P0.025%, Cu0.5%, Re0.1%, the balance is Fe;

[0031] (3) Modification treatment, the modification agent is placed on the bottom of the ladle after being wrapped with iron sheets or tin foil paper, and the molten steel that meets the element ratio requirements...

Embodiment 2

[0040] Take the ball mill liner used in the Φ2700×3600 ball mill used in the current mine concentrator as an example.

[0041] The present invention comprises the following steps:

[0042] (1) Smelting, putting the scrap steel material into an intermediate frequency electric furnace for melting, the melting temperature is: 1630°C;

[0043] (2) Batching, sampling and testing the molten steel in the intermediate frequency electric furnace, detecting the content of each element in the molten steel, and disposing a certain amount of trace elements in the molten steel until the weight percentage of each element in the molten steel reaches the following requirements: C0.35 %, Mn1.2%, Si1.2%, Ni1.2%, Cr1.2%, Mo0.3%, S0.015%, P0.015%, Cu1.5%, Re0.2%, the balance is Fe;

[0044] (3) Modification treatment, the modification agent is placed on the bottom of the ladle after being wrapped with iron sheets or tin foil paper, and the molten steel that meets the element ratio requirements i...

Embodiment 3

[0053] Take the ball mill liner used in the Φ2700×3600 ball mill used in the current mine concentrator as an example.

[0054] The present invention comprises the following steps:

[0055] (1) Smelting, putting scrap steel material as raw material into an intermediate frequency electric furnace for smelting, the melting temperature is: 1615°C, and the scrap steel material is preferably a ball mill liner made of manganese steel that has been scrapped;

[0056] (2) Batching, sampling and testing the molten steel in the intermediate frequency electric furnace, detecting the content of each element in the molten steel, and disposing a certain amount of trace elements in the molten steel until the weight percentage of each element in the molten steel reaches the following requirements: C0.32 %, Mn1.0%, Si0.95%, Ni1.1%, Cr1.0%, Mo0.25%, S0.01%, P0.01%, Cu0.8%, Re0.15%, the balance is Fe;

[0057] (3) Modification treatment, wrapping the modification agent with iron sheet or tin fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com