Method for preparing mixed iron powder cold-pressing pellets

A technology for cold-pressed pellets and mixed iron, which is applied in the field of preparation of mixed iron powder cold-pressed pellets, can solve the problems of many harmful impurities, high energy consumption, and coarse particle size of pellets, so as to reduce environmental pollution and reduce environmental pollution. Good effect of resource utilization and metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

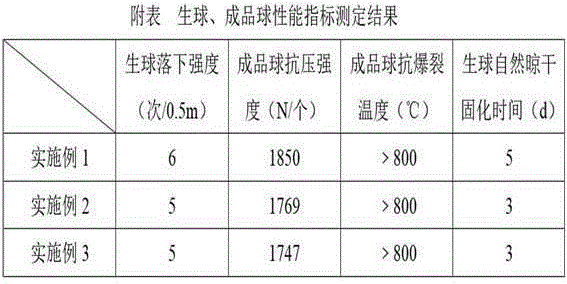

Examples

Embodiment 1

[0017] ①Remove the visible impurities, stones, sawdust, and plastics in the iron ore powder and iron oxide scale powder, and then dry them to make the water content 5%; and control the particle size of the iron ore powder and iron oxide scale powder to 100 mesh;

[0018] ② Weigh 700g of iron ore powder and 300g of iron oxide scale powder, stir and mix for 20 minutes at a stirring speed of 150r / min, and mix evenly to obtain mixed iron powder;

[0019] ③Prepare binder, weigh 15g of bentonite, 3.5g of rapid-hardening portland cement, 1.5g of rapid-hardening sulfoaluminate cement, 3g of sodium carboxymethyl starch, 1g of polyacrylamide, 6g of pregelatinized starch, powdered coal 2g of ash, 1g of magnesium oxide, 1g of calcium carbonate, 1g of gypsum and 1g of cement superplasticizer, stir and mix evenly to obtain a binder;

[0020] ④ Add 1000g of the above-mentioned mixed iron powder, 36g of binder, and 80g of water in sequence in the mixing device with mechanical stirring, stir r...

Embodiment 2

[0023] ①Remove the visible impurities, stones, sawdust and plastics in the iron ore powder and iron oxide scale powder, and then dry them to make the water content 3%; and control the particle size of the iron ore powder and iron oxide scale powder to 120 mesh;

[0024] ② Weigh 700g of iron ore powder and 300g of iron oxide scale powder, stir and mix for 20 minutes at a stirring speed of 150r / min, and mix evenly to obtain mixed iron powder;

[0025] ③Prepare binder, weigh 15g of bentonite, 3.5g of rapid-hardening portland cement, 1.5g of rapid-hardening sulfoaluminate cement, 3g of sodium carboxymethyl starch, 1g of polyacrylamide, 6g of pregelatinized starch, powdered coal 2g of ash, 1g of magnesium oxide, 1g of calcium carbonate, 1g of gypsum and 1g of cement superplasticizer, stir and mix evenly to obtain a binder;

[0026] ④ Add 1000g of the above-mentioned mixed iron powder, 36g of binder, and 60g of water in sequence in a mixing device with mechanical stirring, and stir ...

Embodiment 3

[0029] ①Remove the visible impurities, stones, sawdust, and plastics in the iron ore powder and iron oxide scale powder, and then dry them to make the water content 1%; and control the particle size of the iron ore powder and iron oxide scale powder to 110 mesh;

[0030] ② Weigh 700g of iron ore powder and 300g of iron oxide scale powder, stir and mix for 20 minutes at a stirring speed of 150r / min, and mix evenly to obtain mixed iron powder;

[0031] ③Prepare binder, weigh 15g of bentonite, 3.5g of rapid-hardening portland cement, 1.5g of rapid-hardening sulfoaluminate cement, 3g of sodium carboxymethyl starch, 1g of polyacrylamide, 6g of pregelatinized starch, powdered coal 2g of ash, 1g of magnesium oxide, 1g of calcium carbonate, 1g of gypsum and 1g of cement superplasticizer, stir and mix evenly to obtain a binder;

[0032] ④ Add 1000g of the above-mentioned mixed iron powder, 35g of binder, and 60g of water in sequence in a mixing device with mechanical stirring, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com