A kind of desulfurization gypsum and iron tailings ceramsite and preparation method thereof

A technology for desulfurizing gypsum and iron tailings, which is applied to ceramic products, clay products, other household appliances, etc., to achieve the effects of easy ball formation, improved bonding performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

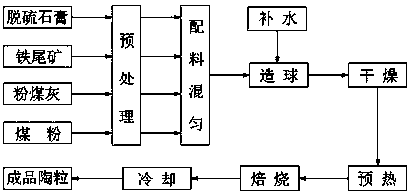

[0040] Such as figure 1 As shown, the raw materials for the preparation of the ceramsite include 13 parts of desulfurized gypsum, 59 parts of iron tailings, 24 parts of fly ash and 4 parts of coal powder by weight percentage. The characteristic steps of the preparation method of ceramsite using desulfurized gypsum and iron tailings as main raw materials are:

[0041] (1) Material pretreatment, desulfurization gypsum, iron tailings, fly ash and coal powder are respectively ground, dried, and passed through a 125-mesh sieve, and the raw materials for the ingredients are obtained from the part under the sieve;

[0042] (2) The ingredients are mixed evenly, each component is weighed according to the weight ratio, and the mixed material is obtained after mixing evenly;

[0043] (3) Pelletizing, adding the mixed material to the disc pelletizing machine to pelletize, the supplementary water in the pelletizing process is added in the form of mist water, and the raw pellets of 5~15mm ...

Embodiment 2

[0050] Such as figure 1 As shown, the raw materials for the preparation of the ceramsite include 15 parts of desulfurized gypsum, 60 parts of iron tailings, 21 parts of fly ash and 4 parts of coal powder by weight percentage. The steps of the preparation method of ceramsite using desulfurized gypsum and iron tailings as main raw materials are:

[0051] (1) Material pretreatment, desulfurization gypsum, iron tailings, fly ash and coal powder are respectively ground, dried, and passed through a 125-mesh sieve, and the raw materials for the ingredients are obtained from the part under the sieve;

[0052] (2) The ingredients are mixed evenly, each component is weighed according to the weight ratio, and the mixed material is obtained after mixing evenly;

[0053] (3) Pelletizing, adding the mixed material to the disc pelletizing machine to pelletize, the supplementary water in the pelletizing process is added in the form of mist water, and the raw pellets of 5~15mm are screened to...

Embodiment 3

[0060] Such as figure 1 As shown, the raw materials for the preparation of the ceramsite include 20 parts of desulfurized gypsum, 55 parts of iron tailings, 21 parts of fly ash and 4 parts of coal powder by weight percentage. The steps of the preparation method of ceramsite using desulfurized gypsum and iron tailings as main raw materials are:

[0061] (1) Material pretreatment, desulfurization gypsum, iron tailings, fly ash and coal powder are respectively ground, dried, and passed through a 125-mesh sieve, and the raw materials for the ingredients are obtained from the part under the sieve;

[0062] (2) The ingredients are mixed evenly, each component is weighed according to the weight ratio, and the mixed material is obtained after mixing evenly;

[0063] (3) Pelletizing, adding the mixed material to the disc pelletizing machine to pelletize, the supplementary water in the pelletizing process is added in the form of mist water, and the raw pellets of 5~15mm are screened to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com