A wide temperature window high-efficiency diesel engine post-processing device and its control method

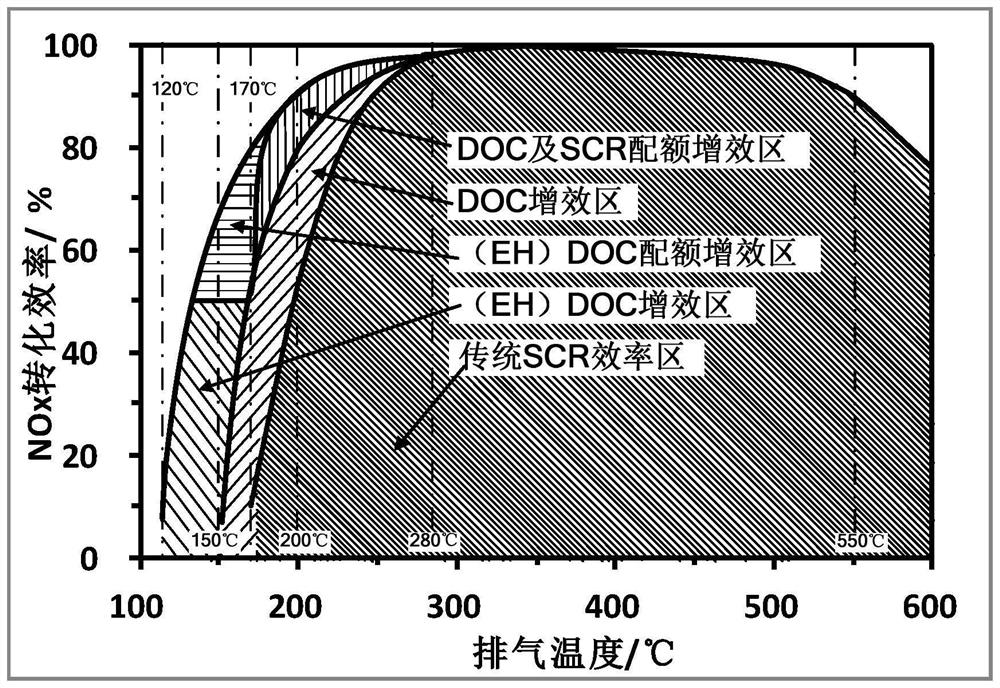

A technology of post-processing device and control method, which is applied in the direction of electronic control of exhaust treatment device, diagnostic device of exhaust treatment device, exhaust device, etc., which can solve the problem of low activity utilization rate, unreasonable distribution, Reduced reliability and other issues, to achieve the effect of prolonging the passive regeneration cycle, saving fuel consumption, and reducing the temperature of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

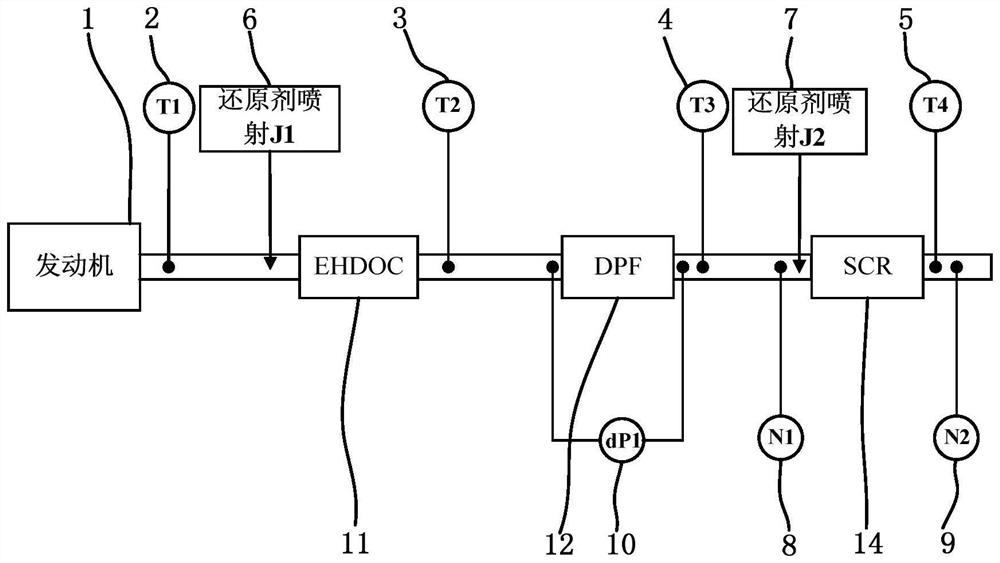

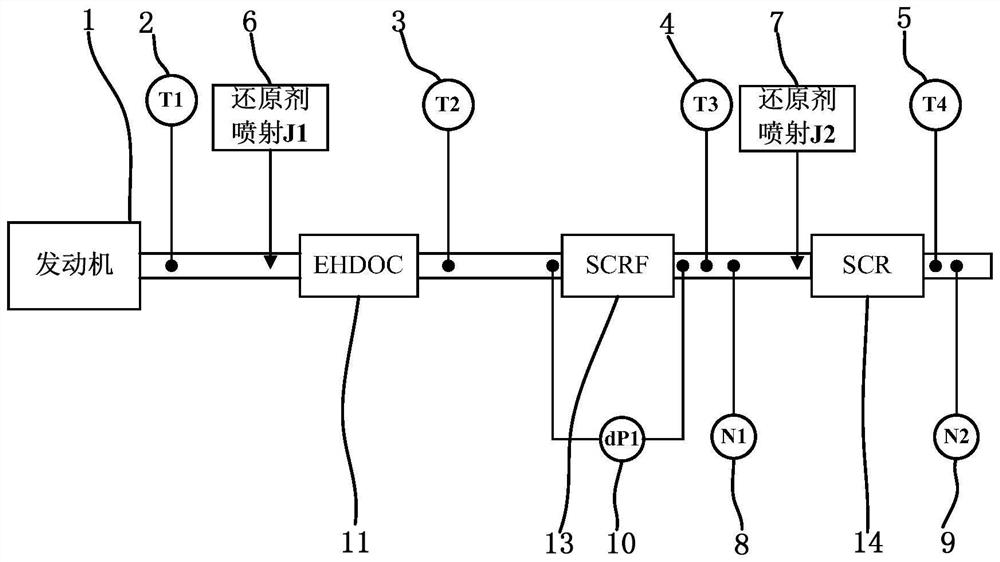

[0035] refer to figure 2 , a high-efficiency diesel engine aftertreatment device with a wide temperature window, which includes an oxidation catalyst 11 with a heating function, a particulate filter 12, a selective catalytic reduction processor 14, a first-stage reductant injector J16, a second-stage Reductant injector J27, first nitrogen oxide sensor N18, second nitrogen oxide sensor N29, first temperature sensor T12, second temperature sensor T23, third temperature sensor T34, fourth temperature sensor T45 and differential pressure sensor; The oxidation catalyst 11 with heating function, the particulate filter 12, and the selective catalytic reduction processor 14 are sequentially connected in series along the exhaust gas flow direction of the engine 1; the first-stage reductant injector J16 is arranged in the upstream of the oxidation catalyst 11; the second-stage reductant injector J27 is arranged downstream of the particle filter 12 and upstream of the selective catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com