Method for preparing hollow ceramic micro-spheres

A technology of hollow ceramics and microspheres, applied in ceramic products, ceramic material production, clay products, etc., can solve the problems of uneven distribution of elements, high cost, high cost of raw materials, etc. The effect of low temperature and raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

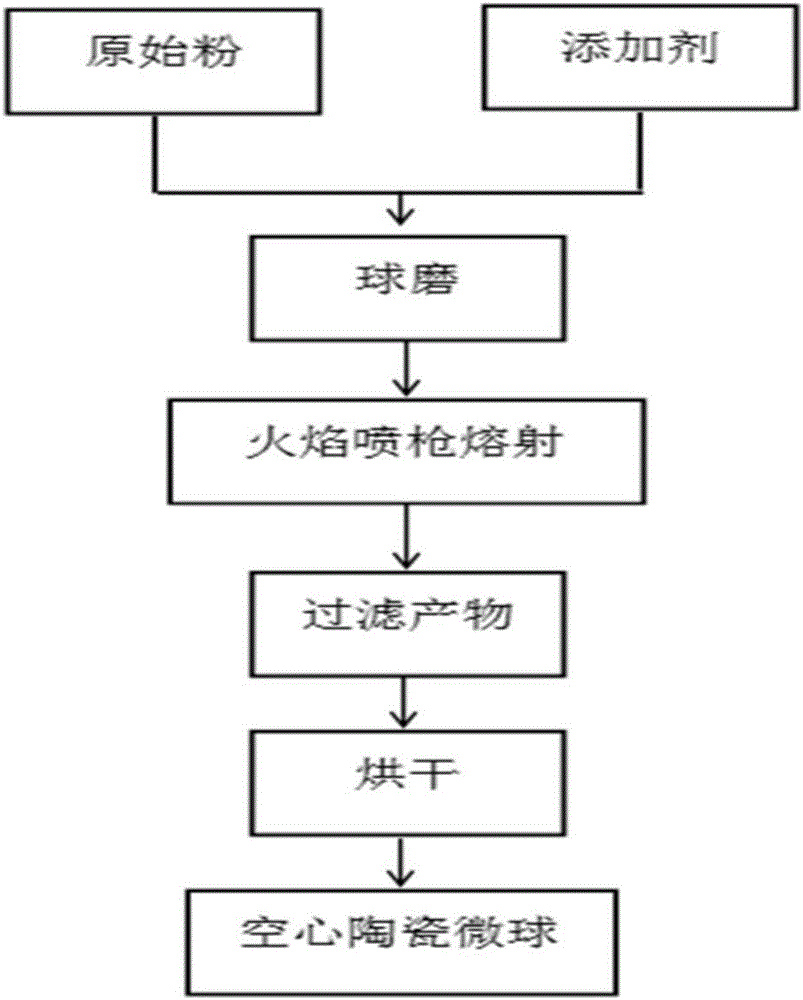

Method used

Image

Examples

Embodiment 1

[0024] 1) Grind the oil shale ash to 400 mesh through a ball mill;

[0025] 2) Take 196g of the ground oil shale ash, add 4g of sodium nitrate, then use a ball mill to ball mill and mix to obtain a mixed powder I containing 2% sodium nitrate by mass;

[0026] 3) Spray the above-mentioned mixed powder I through flame spray gun, where the powder feeding gas is compressed air, the pressure is 0.8MPa, the working gas is air and natural gas, the pressure is 0.1MPa, the feeding speed is 15g / min, and the melting temperature is about The temperature is 2500~3200℃, the quenching distance is 450mm, and the receiving medium is water;

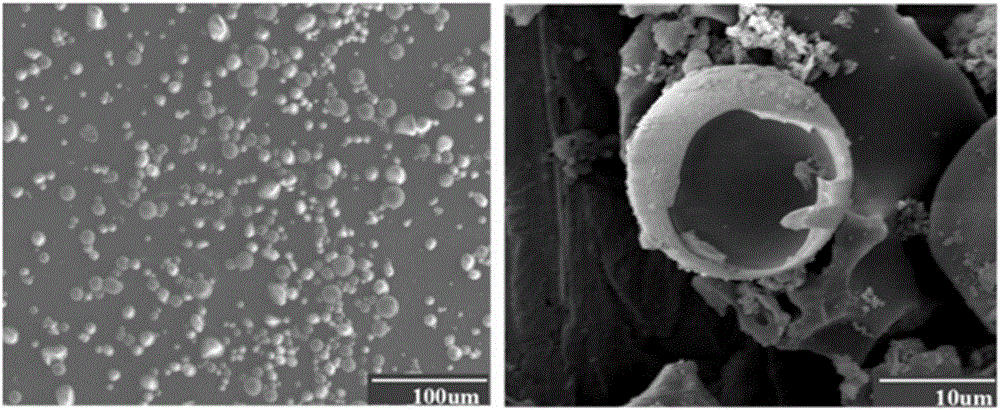

[0027] 4) Separate the spray product in 3) with water, collect the hollow ceramic beads, and dry them in an oven for 3 hours to obtain hollow ceramic microspheres. The outer diameter of the obtained hollow ceramic microspheres is 12-25um, the wall thickness of the hollow microspheres is about 0.5-1um, and the hollowness is 65%.

Embodiment 2

[0029] 1) Grind the oil shale ash to 400 mesh through a ball mill;

[0030] 2) Take 192g of ground oil shale ash, add 8g of sodium nitrate, and then use a ball mill to ball mill and mix to obtain a mixed powder I containing 4% sodium nitrate by mass;

[0031] 3) Spray the above mixed powder I through a flame spray gun, where the powder feeding gas is compressed air, the pressure is 0.8MPa, the working gas is air, natural gas, the pressure of air and natural gas is 0.2MPa, the feeding speed is 15g / min, and the melting temperature The temperature is 2500~3200℃, the quenching distance is 450mm, and the receiving medium is water;

[0032] 4) Separate the spray product in 3) with water, collect the hollow ceramic beads, and dry them in an oven for 3 hours to obtain hollow ceramic microspheres. The outer diameter of the obtained hollow ceramic microspheres is 12-25um, the wall thickness of the hollow microspheres is about 0.5-1um, and the hollowness is 55%.

Embodiment 3

[0034] 1) Grind the oil shale ash to 400 mesh through a ball mill;

[0035] 2) Take 188g of ground oil shale ash, add 12g of sodium nitrate, and then use a ball mill to ball mill and mix to obtain a mixed powder I containing 6% by mass of sodium nitrate;

[0036] 3) Spray the above mixed powder I through a flame spray gun, where the powder feeding gas is compressed air, the pressure is 0.8MPa, the working gas is air, natural gas, the pressure of air and natural gas is 0.15MPa, the feeding speed is 15g / min, and the melting temperature The temperature is 2500~3200℃, the quenching distance is 450mm, and the receiving medium is water;

[0037] 4) Separate the spray product in 3) with water, collect the hollow ceramic beads, and dry them in an oven for 3 hours to obtain hollow ceramic microspheres. The outer diameter of the obtained hollow ceramic microbeads is 6-17um, the wall thickness of the hollow microbeads is about 0.5-1um, and the hollowness is 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com