Technology and apparatus for removing lead, zinc, arsenic, antimony, bismuth and tin from matte

A matte and removal technology is applied in the process and device of arsenic, tin, bismuth, zinc, antimony, and lead removal. Benefit, increase the proportion of ingredients, the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

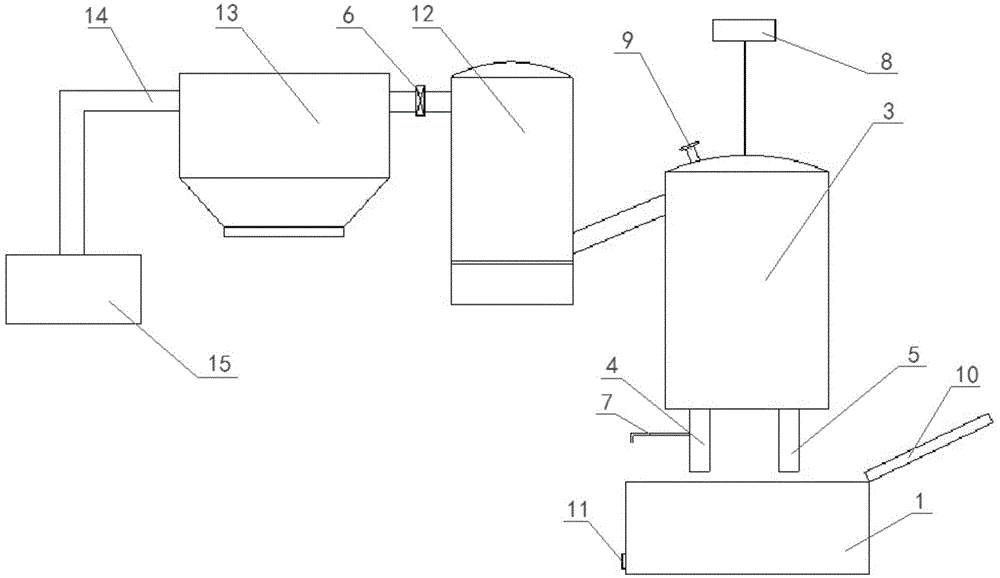

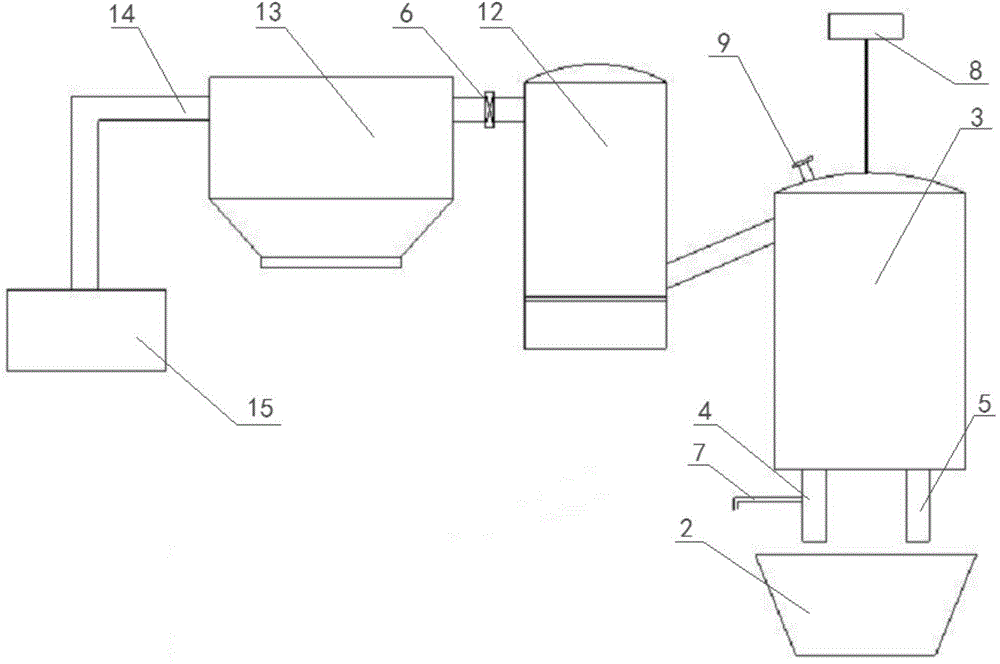

[0053] Embodiment 1 A kind of technology and device for removing lead, zinc, arsenic, antimony, bismuth, tin from matte

[0054] The process of removing lead, zinc, arsenic, antimony, bismuth, tin from matte, the steps are as follows:

[0055] (1) Boil the matte opening of the smelting furnace, and the molten matte flows from the chute 10 into the matte pool 1 or the matte bag 2 .

[0056] (2) Before the molten matte enters the matte pool 1 or the matte bag 2, preheat the vacuum chamber 3 by baking; after the molten matte enters the matte pool 1 or the matte bag 2, stop the baking of the vacuum chamber 3 Bake preheating, withdraw the natural gas burner, and the vacuum system 15 starts pre-evacuation. When the matte melt in the matte pool 1 or the copper matte bag 2 reaches a predetermined liquid level, the vacuum chamber 3 is lowered so that the ascending pipe 4 and the descending pipe 5 are immersed in the matte melt to a certain depth. Open the vacuum valve 6 and evacuate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com