Method for improving hollow balling rate of coal slime floating beads

A technology of pelletizing rate and slime, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of wasting coal resources, difficult to transport slime, low hollow pelletizing rate, etc. The effect of increased feasibility, short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

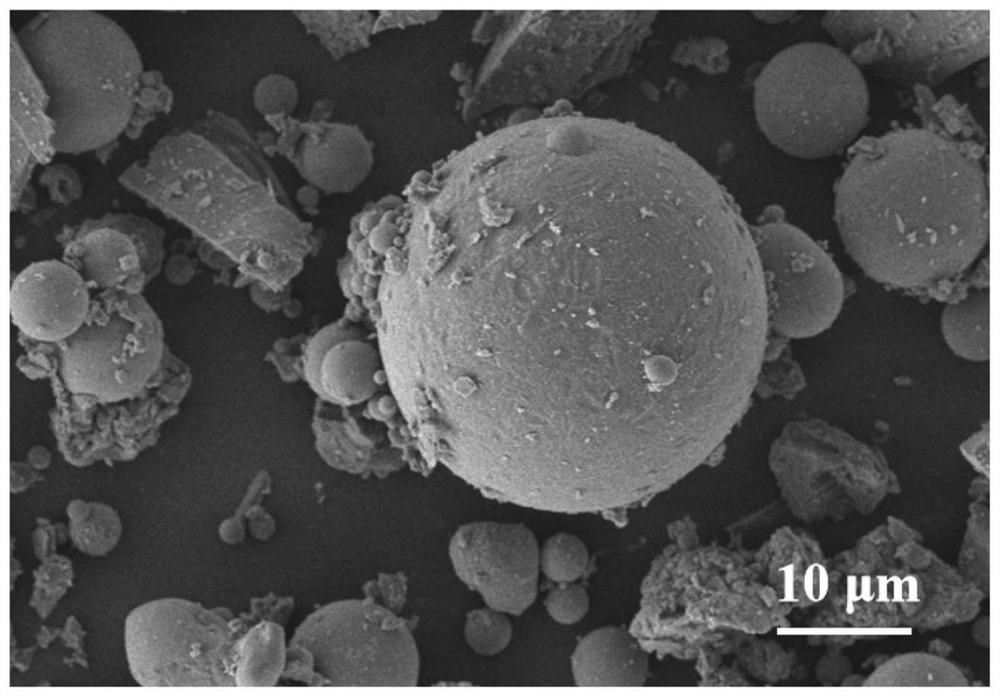

Image

Examples

Embodiment 1

[0026] Coal slime from a coal preparation plant in Shanxi is used. After drying, the main components and content are SiO 2 49%, Fe 2 o 3 5%, Al 2 o 3 33%, C 44%. Dry the coal slime repeatedly and sieve it to below 600 mesh; mix the coal slime powder with a NaOH solution with a concentration of 100g / L, the liquid-solid ratio is 4mL:1g, and grind it in a homogeneous reactor at 200°C for 4h under wet conditions. Filter, dry, grind, homogenize, and pass through a 600-mesh sieve to obtain activated coal slime micropowder. The activated coal slime powder is suspended and roasted in the furnace through airflow control. The roasting temperature is 1600°C. After the suspension roasting reaction time is 10s, the airflow control system is turned off, so that the hollow floating beads are rapidly cooled and quickly separated from the high-temperature furnace when they have not shrunk. The bead hollow forming rate is 66%.

Embodiment 2

[0028] Coal slime from a coal preparation plant in Shanxi is used. After drying, the main components and content are SiO 2 49%, Fe 2 o 3 5%, Al 2 o 3 33%, C 44%. Dry the coal slime repeatedly and sieve it to below 600 mesh; mix the coal slime powder with a NaOH solution with a concentration of 140g / L, the liquid-solid ratio is 4mL:1g, and grind it in a homogeneous reactor at 200°C for 4h under wet conditions. Filter, dry, grind, homogenize, and pass through a 600-mesh sieve to obtain activated coal slime micropowder. The activated coal slime powder is suspended and roasted in the furnace through airflow control. The roasting temperature is 1300 ° C. After the reaction time of suspension roasting is 5s, the airflow control system is turned off, so that the hollow floating beads are rapidly cooled and quickly separated from the high-temperature furnace when they have not shrunk. The bead hollow-forming rate is 57%.

Embodiment 3

[0030] Coal slime from a coal preparation plant in Shanxi is used. After drying, the main components and content are SiO 2 49%, Fe 2 o 3 5%, Al 2 o 3 33%, C 44%. Dry and grind the coal slime repeatedly and sieve it to below 600 mesh; mix the coal slime powder with a NaOH solution with a concentration of 120g / L, the liquid-solid ratio is 6mL:1g, grind for 4 hours in a homogeneous reactor at 200°C under wet conditions, and filter , drying, grinding, homogenizing, and passing through a 600-mesh sieve to obtain activated coal slime powder. The activated coal slime powder is suspended and roasted in the furnace through airflow control. The roasting temperature is 1600°C. After the suspension roasting reaction time is 10s, the airflow control system is turned off, so that the hollow floating beads are rapidly cooled and quickly separated from the high-temperature furnace when they have not shrunk. The bead hollow-forming rate is 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com