Contains nano fe(oh) 3 Preparation method of grafted acrylamide copolymer flocculant

A technology of acrylamide copolymer and grafted acrylamide, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of high dosage of organic polymer flocculants, poor removal of soluble inorganic and organic pollutants, and aluminum residues. Quantity and COD Higher Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

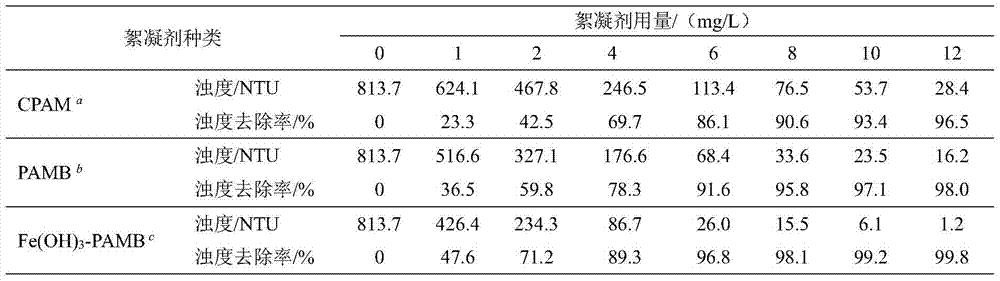

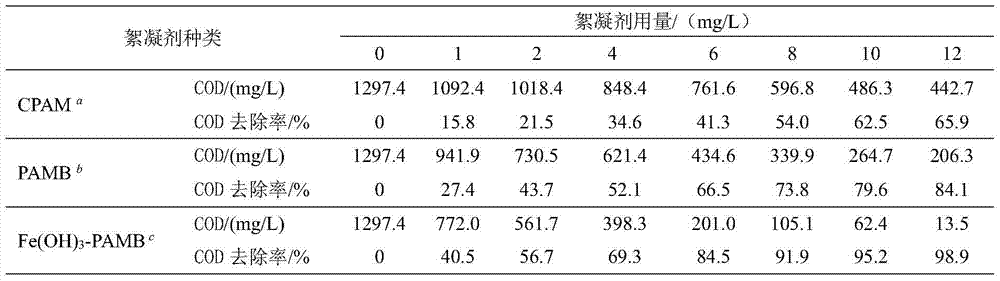

Examples

Embodiment 1

[0020] 10 g FeCl 3 Dissolve in ethylene glycol, prepare 100mL of a solution with a mass concentration of 100g / L, add 100mL of FeCl 3 Add the solution into a three-necked reaction flask, slowly add 95mL of ethylene glycol solution with a NaOH mass concentration of 40g / L while stirring, react for 3 hours under rapid stirring, the reaction temperature is 130°C, then cool to room temperature, and centrifuge the reaction product Separated and washed with deionized water to obtain nano-Fe(OH) 3 . Add 20 grams of acrylamide into a three-necked reaction flask, then add 175 grams of deionized water, stir to form a solution, add 1.250 grams of trimethylhexadecyl ammonium chloride and stir, add nano-Fe(OH) 3 0.980 grams, then add 9.760 grams of dimethyl diallyl ammonium chloride, 4-vinylbenzyl alkylphenol polyoxyethylene ether (the degree of polymerization of polyoxyethylene ether is 16) 1.310 grams, stir 30 minutes, adjust The pH value of the solution is 5.5, pass N under stirring 2...

Embodiment 2

[0022] 10 g FeCl 3 Dissolve in ethylene glycol, prepare 100mL of a solution with a mass concentration of 100g / L, add 100mL of FeCl 3 Add the solution into a three-necked reaction flask, slowly add 160mL of ethylene glycol solution with a NaOH mass concentration of 40g / L while stirring, react for 2.5 hours under rapid stirring, the reaction temperature is 145°C, then cool to room temperature, and centrifuge the reaction product Separated and washed with deionized water to obtain nano-Fe(OH) 3 . Add 20 grams of acrylamide into a three-necked reaction flask, then add 240 grams of deionized water, stir to make a solution, add 2.941 grams of trimethylhexadecyl ammonium chloride and stir, add nano-Fe(OH) 3 1.872 grams, then add 16.530 grams of ethyl acrylate trimethyl ammonium chloride, 2.861 grams of 4-vinylbenzyl alkylphenol polyoxyethylene ether (the degree of polymerization of polyoxyethylene ether is 40), stir for 30 minutes, adjust The pH value of the solution is 5, pass N ...

Embodiment 3

[0024] 10 g FeCl 3 Dissolve in ethylene glycol, prepare 100mL of a solution with a mass concentration of 100g / L, add 100mL of FeCl 3 Add the solution into a three-necked reaction flask, slowly add 210mL of ethylene glycol solution with a NaOH mass concentration of 40g / L while stirring, react for 4 hours under rapid stirring, the reaction temperature is 150°C, then cool to room temperature, and centrifuge the reaction product Separated and washed with deionized water to obtain nano-Fe(OH) 3 . Add 20 grams of acrylamide into the three-necked reaction flask, then add 330 grams of deionized water, stir to make a solution, add 4.260 grams of trimethylhexadecyl ammonium chloride and stir, add nano-Fe(OH) 3 4.503 grams, then add ethyl methacrylate trimethyl ammonium chloride 23.580 grams, 4-vinylbenzyl alkyl polyoxyethylene ether (the degree of polymerization of polyoxyethylene ether is 60) 4.724 grams, stir 30 minutes, Adjust the pH value of the solution to 6.0, pass N under stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com