Dejecta treatment method and system

A technology for excrement treatment and excrement, which is applied in the field of harmless treatment of excrement concentration, can solve the problems of easy damage to seals, high pressure of the pump body, and high pump requirements, and achieve the effects of prolonging the service life, fully mixing and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

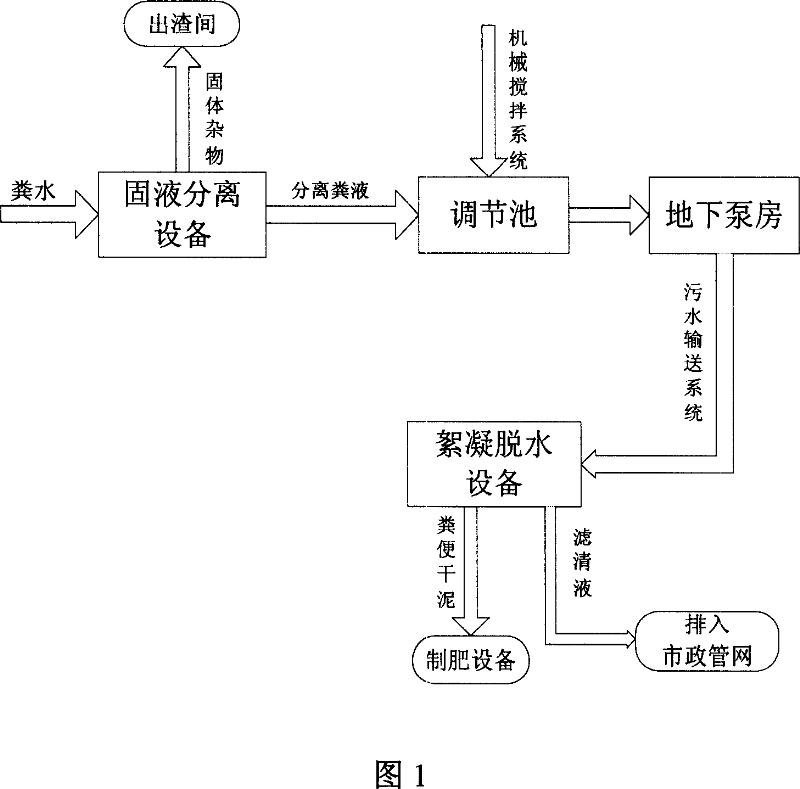

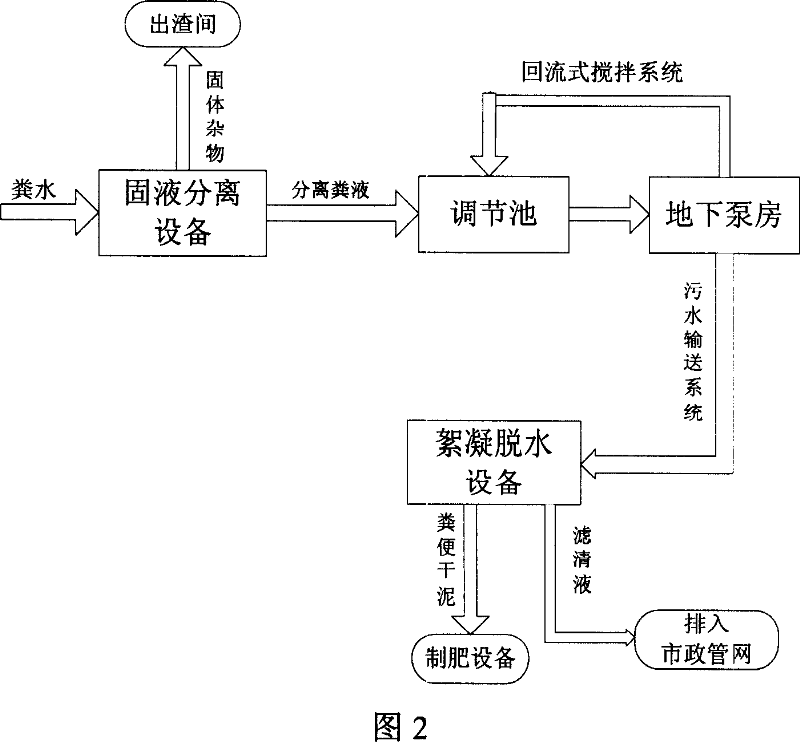

[0037] Figure 2 shows the feces treatment method and system of the present invention. The system includes solid-liquid separation equipment, regulating tank reflux mixing system, sewage conveying system and flocculation and dehydration equipment. Firstly, the solid-liquid separation equipment performs solid-liquid separation treatment on the feces; after separation, the feces are discharged into the regulating tank with a reflux stirring system, and the feces in the regulating tank are discharged by the sewage conveying system; The manure is flocculated and dehydrated.

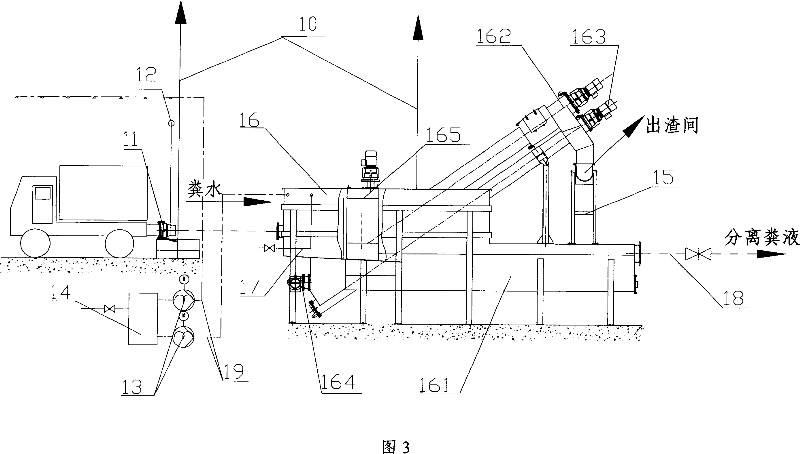

[0038] Figure 3 shows the technical assembly and treatment process of the solid-liquid separation room. As shown in Figure 3, the process room assembly includes a set of excrement discharge port docking device 11, a set of balancing device 12, a deodorizing liquid tank 14, a shaftless screw conveyor 15, and a It consists of a solid-liquid separator 16 for sorting, floating debris crushing, sand removal, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com