High-temperature-resistant anti-oxidation inorganic coating and preparation method thereof

An inorganic coating and anti-oxidation technology, applied in the direction of coating, etc., can solve the problems of poor high temperature resistance, falling off, and reducing the high temperature anti-oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

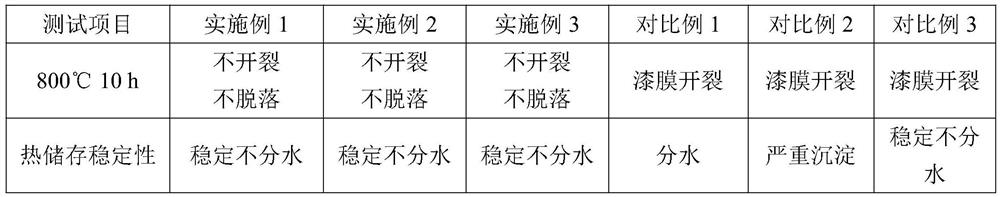

Examples

Embodiment 1

[0020] Adjust the rotation speed to 300 rpm, add 10 parts of water, 0.1 part of hydroxyethyl cellulose, 0.6 part of water-based dispersant, 0.3 part of water-based wetting agent, 0.2 part of water-based defoamer, and stir for 1 minute until the cellulose thickens significantly;

[0021] Add 20 parts of silica sol and 1.0 part of bentonite, and stir for 5 minutes until the dispersion is uniform and transparent;

[0022] Then add 25 parts of alumina, 15 parts of boron carbide, 7.5 parts of mica powder, and 2 parts of calcined kaolin, increase the speed to 1500 rpm, and disperse for 15 minutes until the powder is evenly dispersed in the system;

[0023] Adjust the rotating speed to 500rpm, add 20 parts of silica sol and 0.3 parts of water resistant agent in sequence, and continue stirring for 5-10 minutes to obtain the finished product.

Embodiment 2

[0025] Adjust the rotation speed to 300rpm, add 20 parts of water, 0.4 part of hydroxyethyl cellulose, 0.5 part of water-based dispersant, 0.4 part of water-based wetting agent, 0.1 part of water-based defoamer, and stir for 1 minute until the cellulose thickens significantly;

[0026] Add 20 parts of silica sol and 0.2 parts of bentonite, and stir for 5 minutes until the dispersion is uniform and transparent;

[0027] Then add 20 parts of alumina, 11 parts of boron carbide, 9 parts of mica powder, and 8 parts of calcined kaolin, increase the speed to 1500 rpm, and disperse for 15 minutes until the powder is evenly dispersed in the system;

[0028] Adjust the rotation speed to 500rpm, add 10 parts of silica sol and 0.4 parts of water resistant agent in sequence, and continue stirring for 5-10 minutes to obtain the finished product.

Embodiment 3

[0030] Adjust the rotation speed to 300rpm, add 5 parts of water, 0.3 parts of hydroxyethyl cellulose, 0.4 parts of water-based dispersant, 0.3 parts of water-based wetting agent, and 0.3 parts of water-based defoamer, and stir for 1 minute until the cellulose thickens significantly;

[0031] Add 20 parts of silica sol and 0.4 parts of bentonite, and stir for 5 minutes until the dispersion is uniform and transparent;

[0032] Then add 30 parts of alumina, 7 parts of boron carbide, 6 parts of mica powder, and 5 parts of calcined kaolin, increase the speed to 1500 rpm, and disperse for 15 minutes until the powder is evenly dispersed in the system;

[0033] Adjust the rotation speed to 500rpm, add 30 parts of silica sol and 0.3 parts of water resistant agent in sequence, and continue stirring for 5-10 minutes to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com