Rare earth permanent magnet powder, preparation method thereof, bonded permanent magnet containing same and device

A technology of rare earth permanent magnets and bonded magnets, applied in the direction of magnetic objects, permanent magnets, magnetic materials, etc., can solve the problems of poor anti-corrosion performance and reduced magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Under the teaching of the present invention, those skilled in the art have the ability to select an appropriate method to prepare the above-mentioned rare earth permanent magnet powder. In a preferred embodiment of the present invention, the preparation method of the above-mentioned rare earth permanent magnet powder includes: forming by rapid quenching and heat treatment steps Take Nd 2 Fe 14 B is a rare earth alloy powder with a main phase structure; the rare earth alloy powder is subjected to nitriding treatment in a nitrogen-containing atmosphere to obtain a rare earth permanent magnet powder.

[0048] The preparation method of the above-mentioned rare earth permanent magnet powder provided by the present invention is formed by rapid quenching and heat treatment steps 2 Fe 14 B is a rare earth alloy powder with a main phase structure. This kind of Nd 2 Fe 14 The B structure can ensure that the obtained rare earth permanent magnet powder has certain magnetic pro...

Embodiment 1 to 25

[0087] Metal melting: put various raw materials (Nd, Pr, Fe, Co, B, C, Zr, Ti, Nb, Ga, Cu, Al) into the induction melting furnace in proportion, and melt them under the protection of Ar gas to obtain alloys Ingot.

[0088] Quick quenching: The alloy ingot is roughly broken and put into a quick quenching furnace for quick quenching. The protective gas in the quick quenching furnace is Ar gas, and the number of nozzles is 1. The diameter of the circular nozzle is 0.9mm, and it is sprayed out from the nozzle. After the alloy solution is in contact with the Cu roll, it is rapidly cooled and flew out, and the rare earth alloy powder with an average thickness of 15-100 μm is obtained after rapid quenching, and the phase structure of the obtained rare earth alloy powder is determined by XRD.

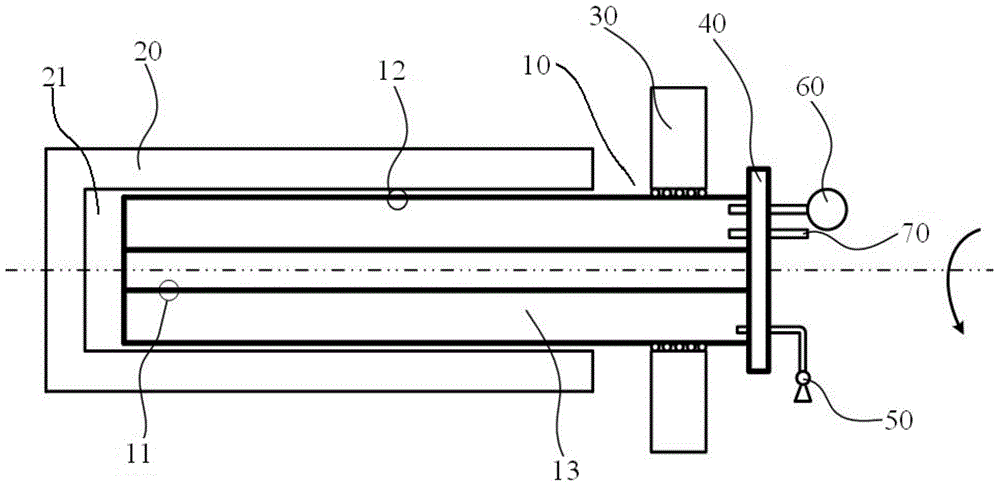

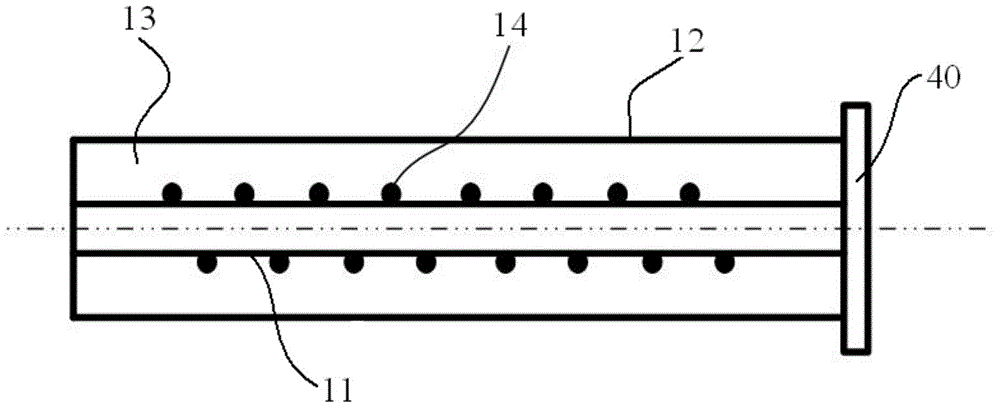

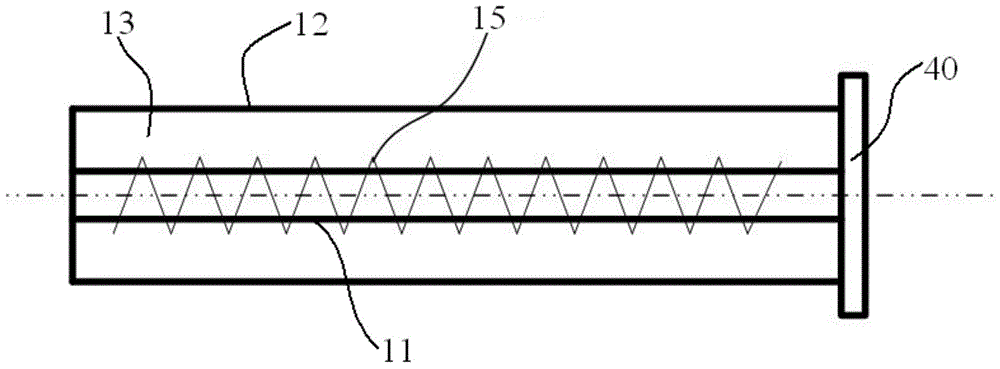

[0089] Heat treatment: put the above rare earth alloy powder in the above rotary heat treatment furnace, heat treatment at 600-800°C under the protection of Ar gas for 3min-60min, and take out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com