Anti-ultraviolet glass film and manufacturing method thereof

A glass film, anti-ultraviolet technology, applied in the direction of film/flake adhesives, coatings, adhesives, etc., can solve the problems of poor perspective, general heat insulation effect, high price, etc., to improve the heat insulation performance, improve the UV protection performance, skin protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

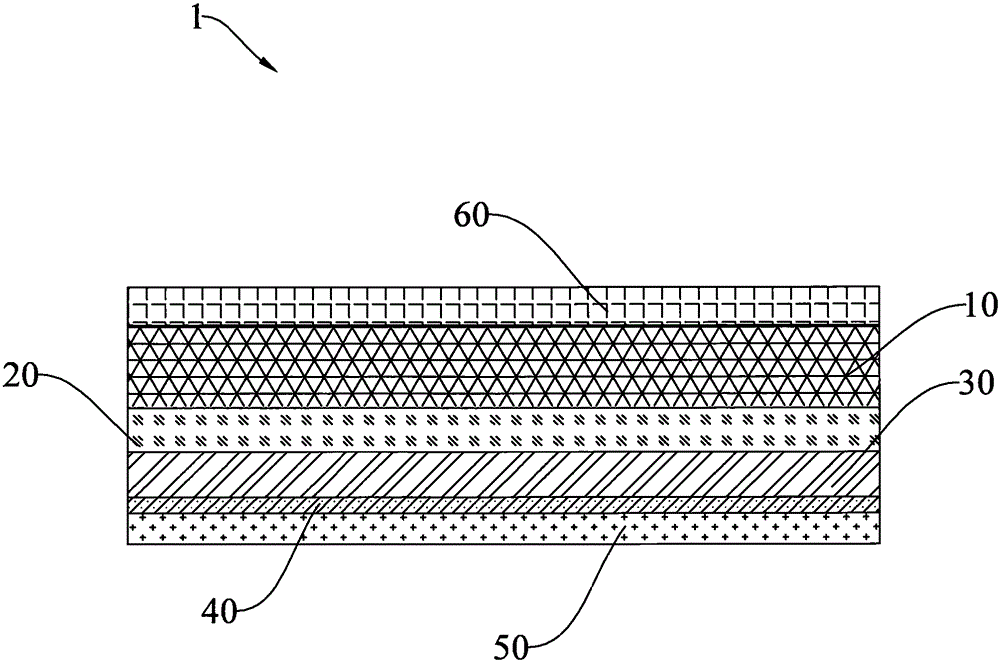

[0055] A preparation method for UV-resistant glass film 1, comprising the steps of:

[0056] S100 provides a base layer 10, wherein the base layer 10 is a polyimide layer;

[0057] S200 coating the water-based epoxy resin containing modified nano-zinc-aluminum oxide and nano-antimony-doped tin oxide on the inner surface of the base layer 10 to form a heat-insulating layer 20;

[0058] S300 coating the water-based polyurethane containing anti-ultraviolet nanocomposite material and anti-ultraviolet additive on the surface of the heat insulation layer 20 to form an anti-ultraviolet layer 30; and

[0059] S400 sequentially coating silicon dioxide and epoxy resin containing nano-alumina on the outer surface of the base layer 10 to form the wear-resistant layer 60 .

[0060] Wherein, the preparation method of the anti-ultraviolet glass film 1 further includes step S500: detachably bonding polyethylene terephthalate to the anti-ultraviolet layer with a polyurethane adhesive to form ...

Embodiment 1

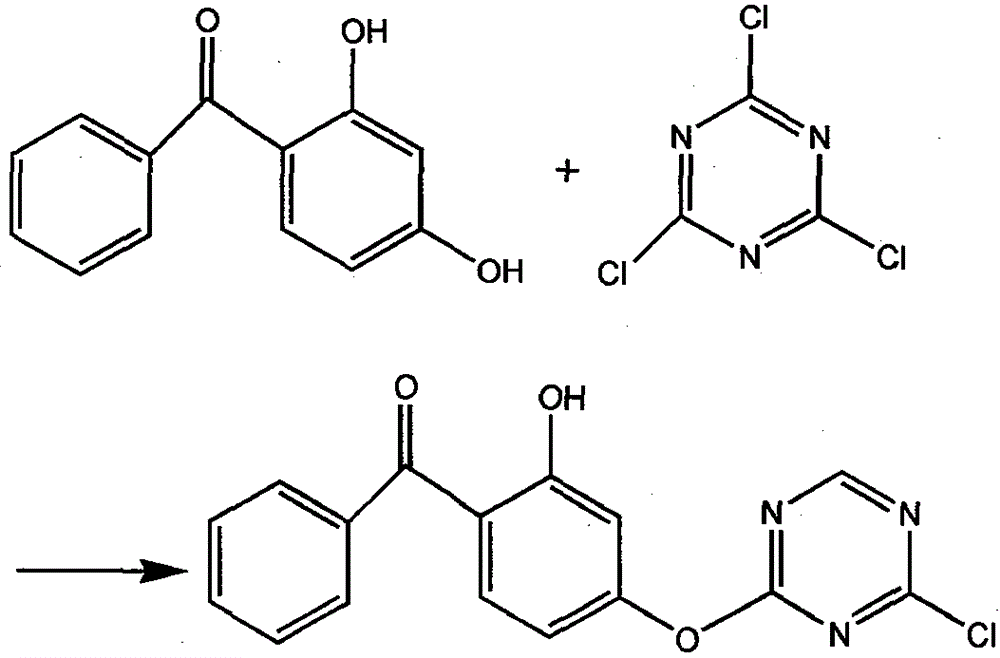

[0080] The step S300 further includes the steps of:

[0081] The anti-ultraviolet nano-composite material is prepared by coating a layer of nano-cerium dioxide with a particle size of less than 100nm by a sol-gel method, wherein 5 parts by mass of nano-zinc oxide are dispersed in 200 parts by mass of absolute ethanol , Then add 5 mass parts of cerium chloride, stir for 5 minutes. Then, 3 parts by mass of acetylacetone was added dropwise to the above solution, sealed and stirred at room temperature for 1 hour, and aged for 2 hours. Centrifuge the above-mentioned zinc oxide coated with nano ceria, repeatedly add 1,2 propylene glycol and ethanol to wash, and dry;

[0082] Prepare anti-ultraviolet nano-composite slurry, 80 mass parts of 4-methyl-2-pentanone, add 3 mass parts of methacrylic acid oxypropylmethyldimethoxysilane, then add 12 mass parts of anti-ultraviolet nano Composite materials, disperse for 8 minutes at 500rpm, and then grind for 25 minutes with a ball mill;

[...

Embodiment 2

[0091] The step S300 further includes the steps of:

[0092] Nano-zinc oxide with a particle size of less than 100nm is coated with a layer of nano-ceria by a sol-gel method to prepare an anti-ultraviolet nano-composite material, wherein 7 parts by mass of nano-zinc oxide are dispersed into 200 parts by mass of absolute ethanol , Then add 6 parts by mass of cerium chloride, and stir for 7 minutes. Then, 4 parts by mass of acetylacetone was added dropwise to the above solution, stirred at room temperature for 1.5 hours, and aged for 2.5 hours. Centrifuge the above-mentioned zinc oxide coated with nano ceria, repeatedly add 1,2 propylene glycol and ethanol to wash, and dry;

[0093] Prepare anti-ultraviolet nanocomposite slurry, 85 parts by mass of 4-methyl-2-pentanone, add 4 parts by mass of methacrylic acid oxypropylmethyldimethoxysilane, then add 10 parts by mass of anti-ultraviolet nano Composite material, disperse for 5 minutes at 480rpm, and then grind for 20 minutes wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com