Polyester base film for window film and manufacturing technology of polyester base film

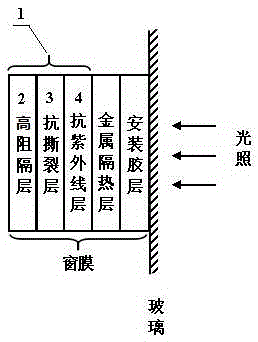

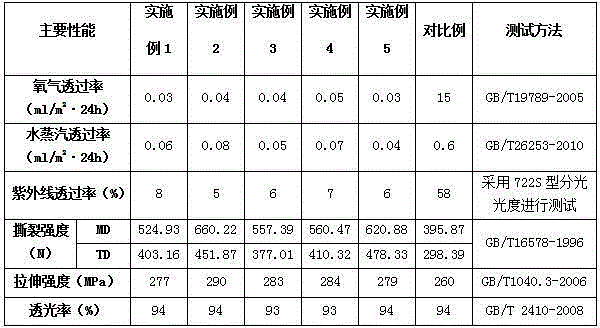

A polyester base film and production process technology, applied in the direction of lamination auxiliary operation, lamination, layered products, etc., can solve the problems of reducing the optical and surface properties of the film, reducing the life of the window film, cracking, etc., and achieving oxygen permeability The effect of reducing the pass rate and UV transmittance, improving the tear resistance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Group ratio:

[0031] The raw material of high barrier layer 2 is made of 0.25% SiO by weight percentage 2 Microparticles and 99.75% optical grade polyethylene naphthalate (PEN);

[0032] The raw material of anti-tearing layer 3 is made of 10% polyethylene terephthalate-1,4-cyclohexane dimethanol (PETG) and 90% optical grade polyethylene terephthalate by weight percentage. Alcohol ester (PET) composition;

[0033] The raw materials of the anti-ultraviolet layer 4 are composed of 1.5% 2-(2'-hydroxy-5'-methylphenyl)benzotriazole, 1.5% PETG, and 97% optical grade PET polyester chips by weight percentage ;

[0034] According to the following production process for production:

[0035] a) Put the raw materials of the tear-resistant layer 3 into a fluidized bed at 140°C and dry them for 4 hours. After the obtained dry raw materials are formulated according to the weight percentage, they are sent to the main extruder to be heated to a molten state as the core layer Melt: ...

Embodiment 2

[0040] Group ratio:

[0041] The raw material of high barrier layer 2 is made of 0.25% SiO by weight percentage 2 Microparticles and 99.75% optical grade polyethylene naphthalate (PEN);

[0042] The raw material of anti-tearing layer 3 is made of 15% polyethylene terephthalate-1,4-cyclohexane dimethanol (PETG) and 85% optical grade polyethylene terephthalate by weight percentage. Alcohol ester (PET) composition;

[0043] The raw material of the anti-ultraviolet layer 4 consists of 1% 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole, 1% 4-benzoyloxy-2,2, 6,6-Tetramethylpiperidine, 3% PETG, 95% optical grade PET polyester chips;

[0044] According to the following production process for production:

[0045] a) Put the raw materials of tear-resistant layer 3 into a fluidized bed at 160°C for 5 hours and dry them for 5 hours. After the obtained dry raw materials are formulated according to the weight percentage, they are sent to the main extruder to be heated to a molten state as th...

Embodiment 3

[0050] Group ratio:

[0051] The raw material of high barrier layer 2 is made of 0.25% SiO by weight percentage 2 Microparticles and 99.75% optical grade polyethylene naphthalate (PEN);

[0052] The raw material of anti-tearing layer 3 is made of 13% polyethylene terephthalate-1,4-cyclohexane dimethanol (PETG) and 87% optical grade polyethylene terephthalate by weight percentage. Alcohol ester (PET) composition;

[0053] The raw material of the anti-ultraviolet layer 4 consists of 1% 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole, 1% 4-benzoyloxy-2,2, 6,6-tetramethylpiperidine, 1% 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorobenzotriazole, 1% PETG, 96% Composition of optical grade PET polyester chips;

[0054] According to the following production process for production:

[0055] a) Put the raw materials of the anti-tear layer 3 into a fluidized bed at 150°C for 4.5 hours and dry them for 4.5 hours. After the obtained dry raw materials are formulated according to the weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com